EFI has marked the 75th anniversary of its Reggiani breand by unveiling a new entry-level digital textile printer, an enhanced version of its EFI Reggiani Terra Silver printer and confirming that a higher-volume EFI Reggiani Hyper model will be launched in July.

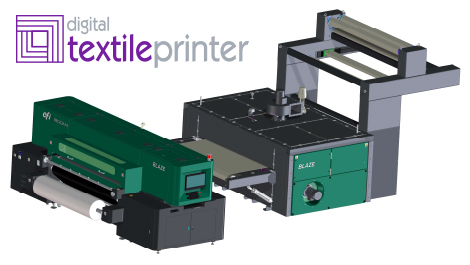

The brand new Reggiani Blaze, a 1.8m printer able to print 225sqm/hr and at 600 x 1200dpi, is designed to give companies the opportunity to enter the digital textile printing market with a compact solution. The industrial printer took centre stage on EFI’s stand at ITMA Asia, currently taking place in Shanghai.

‘Despite the impact of the pandemic, EFI Reggiani has continued to invest and develop the next trailblazing technology for the textile market,’ said EFI Reggiani senior vice president and general manager, Adele Genoni. ‘Our customers are our number one priority no matter how small or big they are. With the EFI Reggiani Blaze, we are able to offer an ideal solution for companies that want to enter the industrial textile digital printing space. We are excited to be able to offer such a solution and look forward to embarking on this journey with our customers.’

EFI Reggiani says that its new printer is one of the fastest printers in its class and offers an ‘innovative, low-maintenance, continuous ink recirculation system equipped with a level sensor and degassing as well as a print head crash protective system for longer printhead life and superior uptime.’ It is also equipped with a continuous and switchable belt washing unit and includes features designed to boost productivity such as a 400mm roll unwinder, expandable shafts, an air gun and a pneumatic bar for standard fabrics.

The company has also updated the EFI Reggiani Terra Silver, a 1.8m wide printer which runs EFI Reggiani’s Terra pigment ink for ‘high-quality, highly sustainable,’ direct-to-textile printing without steaming or washing. New features of the Terra Silver include an ink recirculation system, real-time image processing, several printing modes and a more-efficient polymerisation process that takes place as printed textile goes through the printer’s onboard dryer.

‘Textile has been in our DNA since the beginning,’ Ms Genoni concluded. ‘We are always moving to the next level, thinking ahead and developing high-tech, quality and reliable products as well as new textile industry solutions and processes. We are also pleased to be a part of the success of so many global textile manufacturers and apparel brands over the past seven decades and into the future.

‘We have very close relationships with our customers, and the collaboration we have together allow us to develop groundbreaking new technologies. The three new printers we are launching this year speak to the legacy and expertise for solutions that have made our technologies a benchmark of productivity and quality ever since the creation of the first Reggiani textile printer in 1946.’

Whilst in China EFI Reggiani also confirmed that its Aqua range of water-based reactive inks, suitable for use on cotton, silk, viscose rayon, linen and lyocell, are set to become available in China, where they will also be manufactured.

Full details of the EFI Reggiani Hyper will be made available closer to its official launch next month.

The next instalment of Digital Textile Printer will be published on 24 June, to make sure you receive all the latest interviews, insight and analysis from this booming sector: REGISTER HERE.