Mimaki has unveiled a set of new products, including a 200sqm/hr flatbed UV printer, a dedicated 1.6m roll-fed leather printer and an entry-level full colour 3D printer.

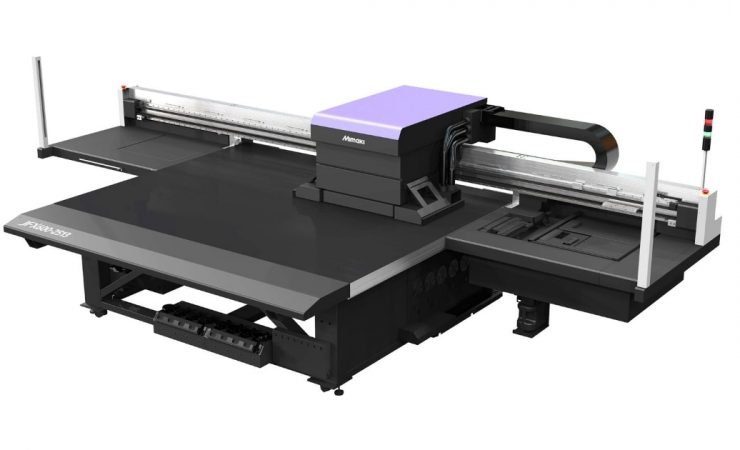

The JFX 550-2513 and JFX 600-2513 mark Mimaki’s entry into the high productivity flatbed sector. The two models respectively are equipped with eight and 16 printheads with the latter able to reach 200sqm/hr in its high speed mode and 140sqm/hr in ‘production’ mode, with two slower and progressively higher quality modes also available.

Based on the existing JFX 500-2131 model, the new additions both have a maximum printing area of 2.5 x 1.3m and can handle rigid media up to 6cm thick, thus supporting the standard 8x4ft board size. Ink options include white, clear and a primer for difficult substrates such as glass and some plastics and metals, in addition to normal CMYK. All six ink sets, which offer differing degrees of hardness and flexibility, are Greenguard Gold certified.

Workflow has been addressed with a new Mimaki Print Controller operator interface, based on that introduced with the Tiger 1800B textile printer. Industry 4.0-style connectivity with robots for loading/unloading , conveyors or barcode readers for integration into automated production environments is achieved via Mimaki’s MDL Command interface. The printers are driven by Mimaki’s Raster Link 7 Rip software. Mimaki Europe’s general manager for sales, Ronald van den Broek, indicated that the likely price range for the new machines would be from around €150,000 for the 8-head machine, and noted that competing units in this productivity category typically range from €200,000 upwards.

An entirely new addition to the Mimaki portfolio, and possibly unique in the world, though Agfa is working on a dedicated digital leather printer, is the SUJV-160, a 1.6m roll-fed leather printer. Using a combined solvent and UV ink set developed by Fujifilm, and available also with a clear ink for printed surface protection, the new machine is capable of up to 9sqm/hr without the clear coating. The combined curing/drying process requires a large post-cure unit which can handle 25kg rolls.

The clear ink is said to provide a high degree of protection against scratching/rubbing, while being highly flexible and resistant to cracking, yet preserving the touch and feel of the underlying leather, something that Mimaki says is a requirement in the high-end luxury leather goods market at which the printer is aimed. Envisaged applications include vehicle or other seat covers, shoes and handbags.

The third introduction is the 3DUJ-2207, a full colour 3D printer that produces items that fit into a volume of 20 x 20 x 7.8cm (WxDxH). Its print control software supports the use of ICC colour profiles to produce accurate colour reproduction. White and clear print materials are also supported in addition to mixed process colours and suggested applications include scale models, prototyping, figurines and gaming as well as educational and medical purposes. Mr van den Broek indicated that a complete ‘portfolio’ that includes a dedicated cleaning solution will be available for around €50,000, again considerably lower than many other competing offerings which he said typically start at €100,000 without the cleaning system and other necessary accessories.

Mimaki is running a series of rather familiarly-named ‘innovation days’ from 2–4 June 2021, at which more details and virtual demonstrations/factory tours will be offered, and its digital showroom will be running continually with new content added each week.

All the new products described here are to become available in late summer of 2021.