Morgana Systems has added two new models to its range of Valiani flatbed cutters: a smaller entry-level version of the Optima model, and a more automated addition to the range, the Omnia, which features an automated feeder.

The Optima V50 is the latest and smallest of the current range of flatbed cutters and is designed for digital printers who need to cut a wide range of substrates in thicknesses of up to 20mm but who are short of floorspace. It is said to be suited to producing mock-ups, prototypes and small production runs without requiring a die-cutter. The single-head cutting system can swap tools in under 10 seconds and the unit is supplied as standard with a tangential cutting tool suitable for materials up to 5mm thick, a creasing tool and a camera which can detect crop marks and enable contour cuts in combination with OptiCrop software. Maximum material size is 55 x 80cm. The oscillating cutter for materials up to 20mm thick is an extra cost option.

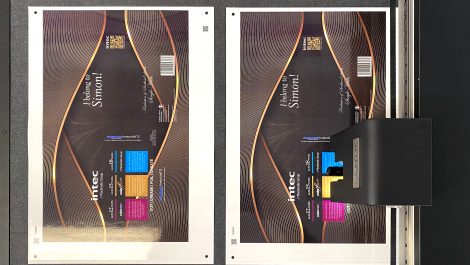

The Omnia combines the substrate versatility of the Optima range with a newly designed sheet feeder and optical registration system,allowing the unit to run repetitive tasks without requiring an operator. According to Morgana it can be left to run unattended overnight, to which end it is equipped with an oversized feeder system capable of holding up to 500 sheets of 350gsm card, delivering work to the 600 x 800mm cutting table. In addition to crop mark detection, it supports QR code recognition, which can be used to load the cut details for each job and automatically carry it out.

Commenting on the new additions, Ray Hillhouse, VP Sales & Marketing for the Plockmatic Group Offline Business Unit, said, ‘These two new units further enhance our range of cutting tables. The Optima V50 addresses the entry level sector, where a small but highly versatile device is an essential ingredient. It’s an ideal starting point for those seeing the need for a cutting table.

‘The Omnia breaks new ground in automating cutting table processes. For those businesses with a growing demand for repetitive tasks, Omnia can produce a great many tasks without the need for an operator to stand over the machine, including ‘lights out’ production of work overnight.’