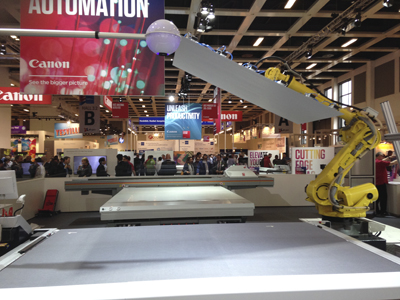

The Canon installation at Fespa

A highlight of Canon’s stand at Fespa was a fully robotised print-and-cut workflow linking the Océ Arizona 6170 flatbed printer with the Océ ProCut cutting table.

The show demonstration was based on a Canon installation at Van Vliet Printing in The Netherlands, where robotisation has enabled 24/7 unattended operation of the Arizona printer and ProCut system, significantly extending the production capacity of the business without needing multiple operator shifts.

The system, integrated by Canon partner robotisation specialist Rolan Robotics, picks unprinted media from a pallet near the Arizona printer and places it in a registration and turning station which registers the media both horizontally and vertically. The robot subsequently withdraws the media and places it with accurate registration on the flatbed for printing. The Arizona automatically receives a machine command to begin printing.

If the substrate is to be printed both sides, the robot returns the media to the turning station and then replaces it on the flatbed to print the other side. An intelligent software interface, developed by Rolan, enables the different devices to synchronise.

When printing is finished, the robot transfers the printed media to the Océ ProCut cutting table. The ProCut software processes the finishing instructions and sends a command to the cutter, without operator intervention. After cutting, creasing or kiss-cutting, the robot can either take all materials from the cutter or, alternatively, lift the finished product(s) from the cutter and transport waste to a container for disposal or recycling. The workflow can also identify repetitive jobs, removing the need for identification and registration for each individual job.