How joined-up thinking between PSPs, OEMs and software developers is unlocking smarter workflows and shaping the future of print.

In today’s print environment – where complexity is rising, costs are climbing, and skilled experts are retiring faster than new blood is joining the workforce – no business can afford to work in a vacuum. From manufacturers and software developers to print service providers (PSPs), organisations are finding great benefit in partnerships.

This approach to collaboration is deeply practical. It is about interoperability, problem-solving, and knowledge-sharing across the supply chain. It is about building relationships that help each party adapt faster, automate more, and deliver better outcomes for end clients. It is about creating a rising tide that lifts all boats together.

Digital Printer magazine spoke to three industry players from across the value chain to explore this approach to business. Software provider Global Graphics, finishing specialist Duplo, and commercial print house Blackmore tell us how cross industry collaboration is already reshaping the way print gets done.

The software perspective: Co-creating the next generation of tools

At Global Graphics, collaboration is no bolt-on – it is a necessity. The company’s flagship software development kit (SDK), Mako Core, and its GPU-accelerated Apex rendering engine have both been developed through close partnerships with OEMs and print providers who are facing the challenges of shifting markets.

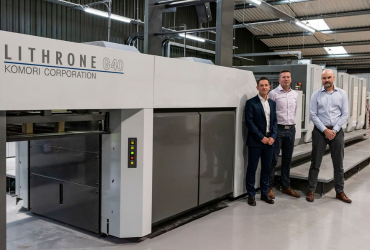

From left: Blackmore directors Andrew Robbins, Simon West, and Nigel Hunt, with the Komori Lithrone G40

“We develop new technology features and functionality in response to requests from our customers who are adapting to changes in the market,” says Global Graphics managing director Justin Bailey. “We listen to their requests and validate that the feature will help the OEM to sell more and will make our technology more appealing to our broader market.”

During development, the company will develop features in response to specific customer challenges, often releasing early versions for joint testing.

“We will often target specific features to meet the exact needs of our OEM customers, sharing engineering releases with them for their testing and validation in parallel to ours,” Mr Bailey explains. “Once approved by the customer and internally by our product owner we will roll the development into our next version of the technology, which is released to the market with a quarterly cadence.”

This process has led to wide platform support, additional programming language wrappers, and compatibility with cloud infrastructure – all built in direct response to customer needs.

Apex, one of the latest innovations, reflects this mindset. It moves rendering from CPU to GPU, delivering “blisteringly fast rendering times that are typically 10X to 30X faster than the same process being performed on the CPU,” says Mr Bailey. It’s particularly effective on jobs involving complex transparency or large format printing.

“With Apex you no longer need to render PDF at low resolution to be able to achieve an acceptable speed,” Mr Bailey adds. “Rendering at print resolutions of 1200dpi or more is almost as fast as when rendering at considerably lower resolutions.”

Even colour accuracy and system-wide efficiency are taken into account.

“Apex also has the colour management from our sister company, Colorlogic, integrated,” says Mr Bailey. “Leveraging the GPU for rendering frees up the CPU so that it can be used in parallel for other tasks.”

Another example is Global Graphics’ SmartDFE solution, which uses Mako to analyse each incoming PDF file and generate a tailored RIP configuration using AI.

Blackmore’s Shaftesbury facility

“Mako accesses all the individual objects in the PDF file and then processes in conjunction with a machine-learning model (AI) that we have trained to know the behaviour of the Harlequin RIP… so that we can always achieve the optimum RIP performance.”

Ultimately, Mr Bailey believes it is only possible to build innovative solutions like these with a collaborative approach.

“Closer collaboration between software provider and OEM or PSP will create increased trust and mutual understanding, accelerating collaboration and speeding time to market for innovation,” he says.

The OEM perspective: From vendor to consultative partner

For Duplo UK, the nature of its customer relationships has evolved significantly. “In today’s print landscape, where rising costs, staffing shortages, and increasing demand for fast-turnaround jobs continue to pressure UK PSPs, collaboration is no longer optional, it is critical,” says managing director Martyn Train.

“Where we once delivered equipment, we now deliver solutions,” he adds. “Our sales team spends time understanding a customer’s unique needs, not just what they think they need, but what they really need to grow sustainably whilst improving efficiency.”

That process often starts with an open conversation. “It’s common for a customer to visit our showroom with one machine in mind and leave with a completely different solution,” Mr Train explains. “That’s not a sales tactic, it is a result of our ability to ask the right questions and explore their production challenges in depth.”

This consultative approach has helped customers like Alan Dakin, owner of Colourbridge printers, make informed choices for their businesses: “Originally, I was in the market for a second-hand folder/creaser. But a visit to Duplo’s showroom quickly changed that plan,” says Mr Dakin. “The DC-618 really stood out as giving me the best bang for my buck.”

Duplo’s collaborations extend to software partners too, such as Fiery. “Nearly 80% of all Duplo DC-618 installations this year have included Fiery integration, enabling full end-to-end automation,” says Mr Train.

Ben Pickard, general manager of Printstore, describes the impact this approach to software and automation has had on the business:

“We’d lost a guillotine operator and instead of rehiring, we invested in the DC-618,” he says. “It’s fully automated, the interface is simple, and best of all, it doesn’t need a skilled operator.”

“I had ten minutes’ training on the DC-618 and that was it and I was away,” adds Martin Cook, Prinstore operations manager. “That’s the beauty of it. It’s touchscreen/PC driven and template based, so anyone tech-savvy can run it.”

Martyn Train, managing director, Duplo UK

For Mr Train, collaboration also means alignment across the value chain. He points to a major joint project with Konica Minolta and the University of Leeds as a standout case.

“It’s a textbook case of how strategic partnerships can deliver real, measurable value,” says Mr Train.

As Ollie Renshaw, business and systems manager at the University of Leeds, explains: “We’ve now started pushing print through the professors and staff straight into the print room,” he says. “Now we produce the very first bit of print that a student sees, their offer letter, to the last, which is their graduation certificate, and everything in between!”

The PSP perspective: Building trust through openness and shared problem-solving

For Andrew Robbins, managing director of Shaftesbury-based print service provider Blackmore, collaboration isn’t new—but it’s never been more vital.

“As a business, we’ve always had quite a diverse range of services that we offer to our clients,” he says. “We were already looking at further diversification, but we took a decision then to look at collaborating with other organisations… both in terms of manufacturers… and strategic partners.”

“In today’s print landscape, where rising costs, staffing shortages and increasing demand for fast-turnaround jobs continue to pressure UK PSPs, collaboration is no longer optional, it is critical.” – Martyn Train, managing director, Duplo UK

One such relationship is with Komori, whose B1 presses are central to Blackmore’s operation.

“We consider the relationship we have with them a partnership,” Mr Robbins explains. “We’re looking to develop new techniques, new ways of offering different coatings, new decorative finishes. And likewise, they’re looking for ways they can help us develop what we can offer.”

This kind of mutual support became especially important during the COVID-19 pandemic, when demand for different services fluctuated rapidly. “There was a feeling, particularly with the other organisations that we work with, that we all wanted to try and help each other navigate our way through an unprecedented time.”

Mr Robbins says that trust is what enables Blackmore to act as a “project printer” – a business that clients rely on to solve problems, even if that means partnering with others or outsourcing elements of a job. And this is something that has proven effective for Blackmore – and its industry friends – through crisis after crisis.

“It’s been one challenge after after the next,” says Mr Robbins, referring to the financial crisis of 2018, Covid, and the current economic uncertainties around the globe. “But I think it’s all about how you adapt, and certainly collaboration has been a big part of that and I can only see that continuing. I see part of our strategy as collaborating with other like-minded organisations as something we’ll do to try and protect us all from the continued volatility in the economy.”

Looking forward, Mr Robbins sees collaboration extending even further – into relationships with creative agencies, education, and knowledge sharing. All elements that will help businesses across the print industry – and beyond – find success and stability in the future.

Collaboration as foundation, not feature

Across software, hardware, and production, collaboration is no longer a luxury – it’s a strategy for thriving in difficult times. It builds speed, reduces waste, and helps companies adapt in the face of relentless change.

“We’re not here to over-spec or push products,” says Martyn Train of Duplo. “We’re here to help printers make the right choice, for now and for the future.”

Justin Bailey, managing director, Global Graphics

“It ensures that we develop technology that will add value for our customers,” adds Justin Bailey of Global Graphics, “and enables both parties to have confidence in their future roadmaps.”

At the sharp end of production, Andrew Robbins of Blackmore has seen the impact first-hand.

“You can’t win every project – but if you’re confident in what you offer, and you collaborate with the right partners, you’ll win more than your fair share.”

In an industry where uncertainty is constant and expectations keep rising, that confidence – and that spirit of collaboration – may just be the difference between standing still and moving forward.