Is cutting powering print’s next giant leap? Chris Brock finds out.

The digitalisation of print has already driven huge industry transformations – faster turnarounds, shorter runs, and endless personalisation – and that transformation has also happened at the cutting table.

Where cutting used to be a matter of scale and cost, today across packaging, signage, and industrial applications, it has evolved to provide versatile and flexible solutions for almost any customer request.

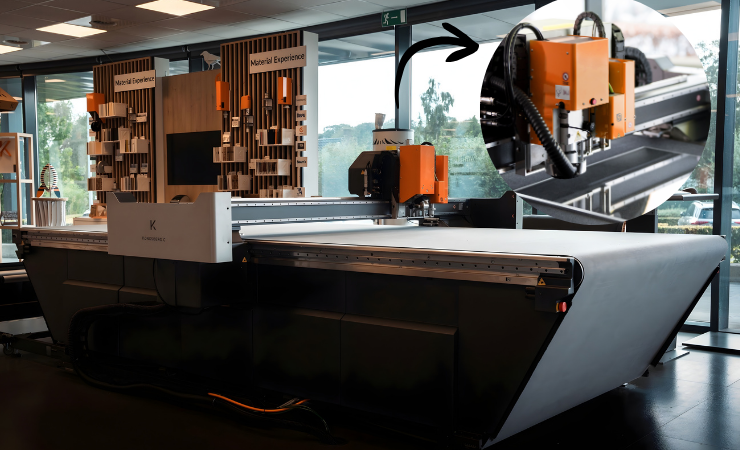

“Thanks to the flexibility of the digital cutting process, you can handle small jobs quite efficiently within short lead times,” says Dimitri van Gaever, global marketing director at Kongsberg Precision Cutting Systems. “It’s a little bit like print-on-demand, but in the finishing world – less obsolescence, less waste, less inventory.”

That ability to produce short, precise runs profitably is reshaping expectations. Printers want equipment that can move between materials and markets without compromise. “If the same table can cut and crease Kongsberg’s cardboard, route acrylic, or cut foam, they don’t need multiple systems,” says Mr van Gaever. “One table, lower footprint – and a faster ROI.”

For Roel Sadelaar, owner of Dutch gasket manufacturer Gelria Pakking, that versatility has been a game changer. “We’ve moved from die-cutting to digital cutting as batch sizes fell and shapes became more complex – the cutting table became the perfect tool,” he says. Using two Kongsberg tables, Gelria now runs production around the clock, grouping jobs by material so machines can process queued orders overnight. “We make products every week that we’ve never made before,” adds Mr Sadelaar. “By saving cut presets per material, even new operators can simply select the substrate and the machine knows the right speed and passes.”

Kongsberg’s Dimitri van Gaever

In Canada, ProPrint CEO Richard Krakower tells a similar story of lean efficiency. “What used to take days across plates, mounting and die-cutting now takes about half an hour – one person prints, cuts, and assembles a full-size production sample,” he says. Automation has allowed ProPrint to optimise staffing in one area of the business from several operators to a single multi skilled worker who moves between devices. “It’s essentially lock, load, and walk away – fewer touches, fewer bottlenecks, and staff focused where they add value.”

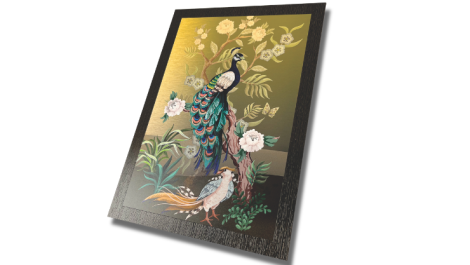

This focus on workflow and convergence is also visible in the graphics sector, where manufacturers like Vivid Laminating Technologies are merging multiple finishing functions into a single digital platform. The company’s new Razar system combines digital die-cutting, creasing, perforating, taping, and raised spot UV – all in a single pass. “Razar was designed to meet the growing demand for shorter run lengths, faster job turnaround, and more premium, creative finishing,” says Vivid director, Lewis Evans. “Because it’s fully digital, every job – even a quantity of one – can be produced efficiently and profitably.”

By eliminating dies and separate setups, systems like these make high-end finishing accessible to smaller PSPs while reducing waste and energy use. The result is a leaner, more responsive production chain in which creativity and efficiency reinforce one another, and PSPs can diversify their offerings.

“The markets are converging – packaging, display, décor, and promotional work – and print providers need equipment that can move with them,” says Mr van Gaever.

Mr Evans agrees, adding: “Designers and print buyers now have far greater creative freedom. They can experiment with intricate shapes, textures, and raised effects, even for short runs or one-offs.”