The new economics of B2 and large-format press investments.

Any business weighing up a major investment has always had to balance risk with potential reward. But as energy prices rise, sustainability targets tighten, and automation becomes the new baseline for efficiency, the maths is changing. Forward thinking PSPs look beyond the initial purchase price, assessing total cost of ownership, uptime, data integration, and long-term future-proofing.

For those looking to invest in large format presses, this represents a change in mindset, towards smarter, more sustainable production that keeps paying back over time.

Productivity, uptime, and the real ROI

In today’s market, uptime and automation often de ne profitability more clearly than the cost of consumables. Heidelberg’s head of software solutions, Paul Chamberlain, advises PSPs to view a press as part of an integrated production system. “High throughput, automation, and hybrid work ow all reduce labour and downtime, improving ROI,” he explains.

He points to Heidelberg’s Jet re 75 as an example of how efficiency can change the equation. “Reduced setup times, lower maintenance overhead, increased job flexibility, and the elimination of plates and makeready waste sheets all contribute to a lower total cost of ownership.” Mr Chamberlain adds that automated colour management and “sorted output to eliminate finishing steps” are among the hidden factors that accelerate payback, while the “strongly reduced CO2 footprint” of presses like the Jet re 75 contribute to longer-term sustainability goals.

For Andrea Connor, worldwide solutions marketing manager at Kodak, uptime is equally central to the investment story. “Higher reliability and fewer interruptions directly translate into greater productivity and reduced labour costs,” she says. “Kodak Ultrastream and Stream Inkjet Technology deliver continuous flow of ink, resulting in fewer jet-outs and quality issues, and high productivity.”

The Heidelberg Jetfire 50

She argues that true ROI can only be calculated by factoring in “ongoing costs alongside expected output, job diversity, and the ability to take on new types of work that may command higher margins.” Ms Connor points to Kodak’s proactive maintenance systems as examples of how technology can help protect that productivity over the long term: “The Prosper log viewer allows our experts to look at press data at a granular, minute by-minute level to identify root causes and potential issues. Additionally, Kodak is developing more automated, AI-supported monitoring and analysis methods.”

Andy Gregory, sales director at Hybrid Services, the UK Mimaki distributor, agrees that productivity and reliability outweigh any temptation to choose purely on price. “While a lower price tag can be tempting, it isn’t always the right solution,” he says. “We encourage PSPs to look beyond the upfront cost and think about the total cost of ownership. That means factoring in ongoing expenses such as ink, energy use, maintenance, and downtime, as well as reliability, productivity, and the costs and benefits of extended warranty programmes.”

Mr Gregory adds that Mimaki printers “are designed with efficiency and longevity in mind, helping customers see a faster return on investment through reduced energy consumption, minimal ink waste, and consistently high-quality output.”

Energy, waste, and sustainability

With energy costs now a major operational concern, the efficiency of curing and drying systems, ink chemistry, and work ow automation all play a direct role in profitability. Mr Gregory notes that sustainability and cost savings increasingly go hand in hand. “Mimaki’s UV printers, such as the UCJV330-160, offer exceptionally low running costs thanks to their UV LED curing system, which instantly cures the ink during printing,” he says. “Compared to latex and solvent alternatives, these systems consume significantly less power while maintaining high productivity and print quality.”

Mimaki’s RasterLink7 RIP software adds another layer of savings through an ink-saving mode that can, Mr Gregory says, “reduce ink usage by up to 30% without affecting colour balance.” Innovations like these have a real influence on purchasing decisions, as customers increasingly seek technology that delivers cost savings, reduced environmental impact, and faster turnaround times without compromising on results.

Kodak has also made sustainability a central design principle. “Kodak Prosper Presses maximise energy efficiency with state-of-the-art drives and energy-saving near-infrared (NIR) inline drying technology,” says Ms Connor. “The presses use eco friendly, water-based Kodachrome and Ektacolor inks. These inks do not contain any VOCs or environmentally hazardous substances, which benefits sustainability and improves the working environment for press operators.”

Ms Connor highlights waste reduction, such as that achieved through Kodak’s Intelligent Print System (IPS), as an important consideration in terms of cost reduction and sustainability: “IPS ensures peak output by continuously monitoring and evaluating system operation… making up to five real time adjustments to the image data on every printed page.” The company even offers a refurbishment programme for worn printheads as a sustainable alternative to replacing them with new ones, conserving resources while allowing hardware and firmware to be updated.

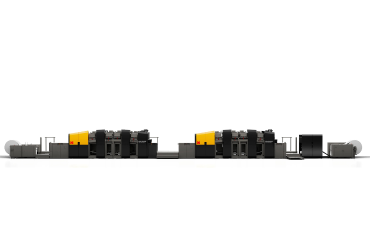

The Kodak Prosper 7000

Heidelberg’s approach follows a similar logic, combining energy efficient hardware with process automation to cut waste. Chamberlain says that water-based inks, automated workflows, and the elimination of offset plates and makeready waste “strongly reduce the CO2 footprint” while maintaining industrial-scale productivity. For PSPs, these efficiencies not only meet environmental targets but also lower the cost of each printed sheet.

Futureproofing and flexibility

Investment longevity is another defining factor. As print markets continue to diversify –from packaging and décor to short-run commercial print – PSPs want assurance that today’s purchase can evolve tomorrow.

Heidelberg’s answer lies in modularity and connectivity. Chamberlain describes presses such as the Jet re 75 as a strategic investment for PSPs navigating digital transformation, citing its “modular design, full integration into the AI-driven Prinect Touch Free work ow, and extreme flexibility in production changes from offset to digital or vice versa in seconds.”

For Kodak, the key is open architecture. “Choose a production inkjet solution with open architecture to easily integrate with existing equipment and workflow systems,” Ms Connor advises. “Open architecture can lower costs, simplify setup, increase productivity, and speed up your return on investment.” She notes that Kodak’s Prinergy Workflow Platform “helps PSPs optimise press usage, monitor performance, and make strategic decisions by leveraging Rules-Based Automation to streamline workflows and reduce manual intervention.”

Mimaki, meanwhile, is pushing connectivity through the cloud. “With Mimaki’s new PICT software, users can monitor their printers remotely, tracking performance, ink levels, and production data straight from a remote phone or laptop,” says Mr Gregory. “This gives PSPs greater visibility and control, even when they’re away from the machine.” Combined with the ID Cut automation system, which allows a cutter to scan barcodes and complete an entire roll unattended, the result is “fully automated print-then-cut workflows” that free up operators for higher-value work.

Think beyond the price tag

Across every segment of the B2 and large-format market, a common message emerges: price alone no longer defines value. Long-term efficiency, sustainability, and adaptability are the new metrics for ROI.

As Hybrid’s Andy Gregory concludes, “Think beyond the price tag and focus on what the printer can do for your business in the long run. A printer isn’t just a purchase for your current situation; it’s an investment in your future growth.” For PSPs making their next move, that might be the most reliable return of all.