UK-based The Delta Group has acquired its third EFI press, an EFI Nozomi 14000 SD single-pass printer for sign and display.

This printer adds to two previous Nozomi acquisitions, a C18000 printer for corrugated and a 18000+ LED printer for sign and display, rounding out its high-volume digital production capability which will help them finish their migration from offset to digital.

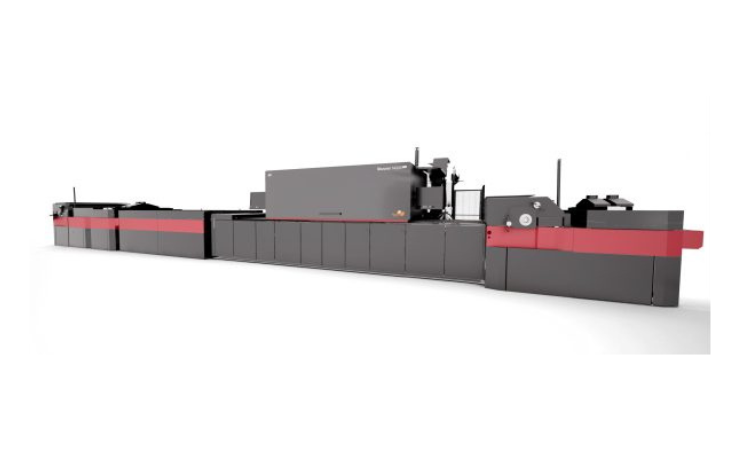

The EFI Nozomi 14000 SD printer was designed to specifically meet the needs of the sign and display graphics market, giving users the opportunity to significantly improve speed to market and increase profitability with a wide range of substrates and colour quality.

The Delta Group, in business for more than 35 years, is an end-to-end visual communications solutions provider predominantly serving the retail industry. Headquartered in Waltham Cross, Hertfordshire, UK, the company has four other locations around the UK, including in Dublin, Ireland. The company offers a range of services, from creative, to manufacturing, installation, digital signage, and is in the final stages of opening a new, highly sustainable facility which will replace the current hub centre.

The Delta Group was the first company in the UK to install a Nozomi press. ‘Once we have made the transition to our new facility,’ said Martin Shipp, the group’s chief operating officer, ‘I believe we will be the first company in the world to have three Nozomis under one roof.’

Mr Shipp added, ‘With our distributed platform, we receive orders centrally and distribute them to the site best suited for the type of work required. Meeting the customer’s requested delivery date is paramount to us.

‘In our main facility we had 13 flatbeds running. But with the Nozomis being up to five or six times faster than even the fastest multi-pass machines, we have been able to reduce our flatbed footprint down to about five across our network.’

Mr Shipp explained that the company has an efficient workflow in place, including customer-facing portals, and many jobs run through automatically where the first human touch is taking the prints off the back end of the printer, with some 500 orders per day being printed in this way. He also noted that whereas in the past, the company would produce overruns of a dozen or more in case some sheets had defects. Now, due to the inline quality control cameras on the Nozomi printers, he said, they only run one or two sheets over.

Key drivers for The Delta Group in shifting from offset and flatbeds to Nozomi printers were the shortened turn times and run lengths. Mr Shipp explained, ‘Historically, retailers would order run lengths of 3000 or more, suitable for offset. But now, instead of campaigns having five different items with a couple thousand of each, we are more commonly seeing campaigns that contain 250 different items with an order quantity of 500-ish each. So, it has really pushed the transition from analogue to digital for the group.’

Mr Shipp concluded, ‘We have realised that Nozomi is clearly the most reliable press we have ever owned. Downtime is extremely minimal, and we get great remote support from Spain. We are now producing more than five million square metres on each one of the Nozomis each year with virtually no downtime.’