Ricoh has used its Print Evolution Live open-house event to launch the Auto Color Adjuster, a stand-alone hardware and software unit that simplifies colour management of digital presses, as well as giving some insight into the progress to market of its Pro Z75 B2 inkjet press and further high-end inkjet developments.

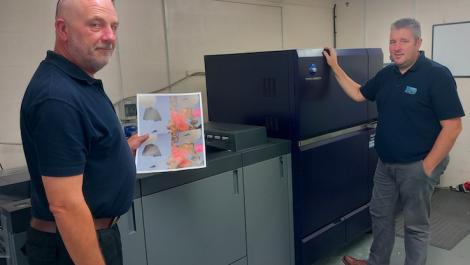

The open house event at the company’s Customer Experience Centre in Telford, Shropshire, was attended by some 65 UK customers and included presentations of the recently launched Pro C7500 and Pro C9500 toner presses, Ricoh’s software and workflow portfolio and a demonstration of the new Auto Color Adjuster.

The latter is designed to de-skill colour management by providing a simple one-touch approach to measuring calibration charts for ICC profile building, or printed samples in order to provide accurate matching of existing work, across multiple print devices and over time. The floor-standing unit has a built-in spectrophotometer and auto-feed that can read a patch chart in around 20 seconds.

It offer three modes: Quick Adjust which checks press calibration and compensates for colour deviation; Verify, which enables test charts containing Fogra Media Wedges to be generated and measured, with pass/fail certification; and Spot Colour which allows for matching of existing samples by scanning the sample to be matched, plus a ‘raw’ print from the press in question and automatically generating a device-link CMYK-to-CMYK correction profile to make subsequent new prints match the sample.

Ricoh’s commercial print sales director Tim Carter spoke to Digital Printer and revealed that the announcement of a UK customer site for the company’s long heralded Pro Z75 inkjet press is due ‘within the next few weeks’; installation at a French site is presently underway, with one to follow in the Netherlands, and a fourth is expected by the end of the current financial year. Mr Carter said that the fourth machine could possibly also be placed in the UK.

‘We are scaling manufacturing in Japan and getting the spares, support and infrastructure in place to ramp up installations significantly,’ he confirmed. Describing the target customer for the B2 press, he explained, ‘It has been designed to have the broadest appeal possible, for general commercial printers moving standard offset pages to digital.’ Target businesses include online printers and gifting/greetings cards producers; Mr Carter also noted that the press’s ability to handle stock up to 600microns thick would suit some packaging applications – helped by its water-based inks – and said that it has been designed to ‘open up and expand opportunities both for Ricoh and its customers’.

There is an optional primer for the Pro Z75, he added, ‘but the aim aim is to not to have to use it, as the press prints on silk, matt and coated papers without it’, and the primer was intended for use with speciality media or some types of uncoated stock. He also explained that the dryer, critical to presenting flat dry sheets in duplexing work, uses a patent-applied-for directed heat technique that focuses on the imaged area.

Reference was also made during a general presentation to a forthcoming ‘new [inkjet] platform’ that would use AI and automation to ‘match offset productivity’. Few further details were given but Mr Carter likened the next step to the difference between Ricoh’s VC60000 and VC70000 models (both of which have evolved since their introduction) and implied that speed, quality and substrate flexibility were all in line to be further improved. More information about this is expected in a month or so. Both this and the Pro Z75 will be on display at drupa 2024.