Muller Martini has introduced two new perfect binders, one optimised for digital print production, and shipped a compact web-fed book block production system announced in 2022.

The new Antaro perfect binder is available in two versions. It is described as a compact perfect binder platform that is suitable for highly flexible use. In on-demand applications, it can produce digitally-printed single books at up to 2000 cycles per hour, an output rate that Muller claims no other machine currently on the market can match, and with the lowest staffing levels. In the conventional version, it delivers up to 4000 cycles per hour.

The Antaro models enable digital nearline or inline production as well as conventional production, and so cater for a wide range of customer requirements. Muller says it also offers a high level of investment protection, because the system can be expanded and adapted on a modular basis.

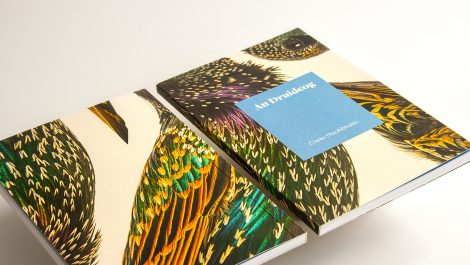

Antaro Digital offers fully automated single-book production with manual feed or inline connection to the SigmaLine Compact digital book production system (see below). With six clamps, up to 2000 individual books can be produced per hour. The regular Antaro version can achieve 4000 cycles/hour in combination with a gathering machine and a three-knife trimmer.

The units’ compact design is said to reduce floorspace and to require fewer than half the number of operators of alternatives. A swing clamp system allows continuous production of books with automatic adjustment for up 20mm thickness variance from book to book. Both EVA and PUR glues are supported, and a newly designed drum cover feeder and cover buffer for the digital version plus barcode reading ensure matching of covers to inners.

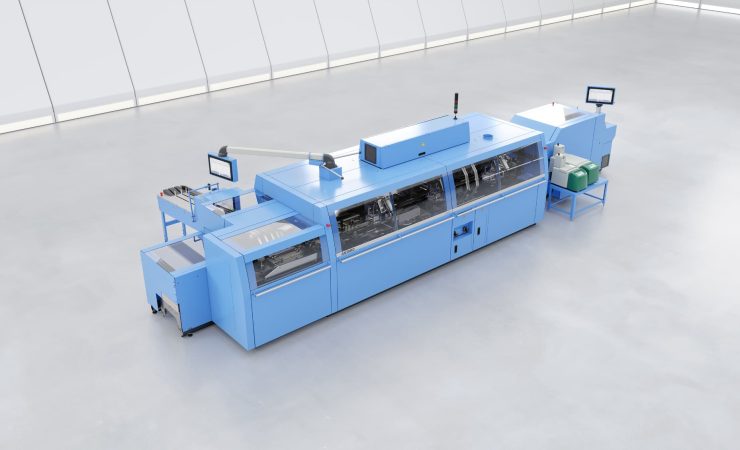

Muller is also now shipping the SigmaLine Compact book block system for use with roll-fed digital presses. The unit has a variable configuration but occupies only 40sqm of floor space. Muller says it can change folding schemes – from three across to four across, for example – in 10 seconds, increasing productivity and reducing set-up and changeover times via the Connex workflow. Waste generated during format change is limited to a few metres, and as with the Antaro units, less operator supervision is required.

The SigmaLine Compact handles rolls up to 22.5in (571mm) wide and embodies Muller’s ‘air knife’ folding technology found in the larger SigmaLine III units. It is suitable for producing blocks for softcover, hardcover, thread sewed and saddle stitched products.