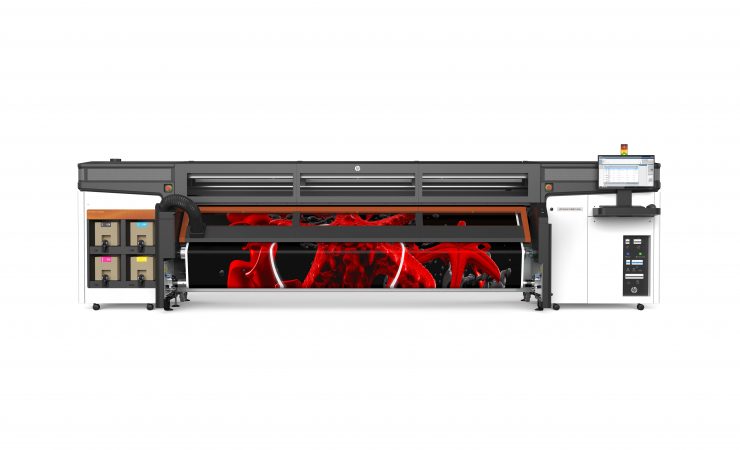

HP has updated its 3.2m Stitch S1000 dye sublimation printer with a number of hardware and software enhancements that improve quality in certain applications and boost overall productivity.

The S1000 ‘2021 edition’ features a new secondary dryer, the Contact Heater, which HP says improves the colour saturation achievable in direct-to-fabric (DtF) printing of back-lit display materials, flags and front-lit products. Reflecting the improved capabilities in DtF printing, HP has also produced a new set of colour profiles for various fabric materials and transfer paper.

The Contact Heater also allows faster warm-up times, which HP says mean that the whole loading, warm-up and printhead cleaning cycle is faster, to make the most of the S1000’s productivity (up to 220sqm/hr for most applications, 130sqm/hr for backlits). Also new on the hardware side is the addition of a dual roll adapter that allows two 1.6m rolls to be printed simultaneously, and an aerosol and vapour extraction system that is said to improve reliability for DtF printing.

Colour consistency across printer fleets is managed via the built-in spectrophotometer and software support in the Configuration Centre, part of HP’s Print OS workflow, allowing load balancing across different machines. Remote monitoring of Stitch printers is also improved via the Print Beat software component.

Introduced at Fespa 2019, the Stitch S1000 can print both DtF and to transfer paper with the one set of dye sublimation inks, as can the smaller 1.6m S300 and S500 models launched the month before.