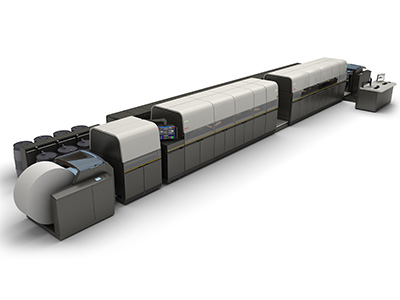

The Prosper 5000XL is currently top of Kodak’s inkjet family.

Installation and commissioning of the UK’s second Kodak Prosper 5000XL full-colour inkjet web press is well under way at the Nottingham direct mail site of DST Output, the major international print group. The site is well known in the industry as the former Howitt web offset factory.

As part of an update on company activities Nick Dixon, CEO of DST’s UK customer communication division, said that the new Prosper press ‘is being commissioned to provide high volume, fully dynamic colour digital solutions on a wide range of paper stocks.’ He also announced expansion plans for all-digital ‘white paper production’ at DST’s Bristol site including another fast digital press, and a second Ricoh InfoPrint 5000 inkjet for financial work at Dagenham.

The Prosper 5000XL is currently top of Kodak’s inkjet web press range, costing in the region of £2.7 million, though the need for revised computer facilities and finishing updates would raise this considerably. The 5000XL offers speeds up to 200 metres per minute on web widths of 622 mm. It’s a 4/4 single-pass twin unit duplex configuration, intended for very high volume, high quality print work. Although an even faster, 300 metres per minute Prosper 6000XL was announced at drupa, it isn’t shipping yet. Existing 5000XLs will be upgradable to 6000XL standard.

The only other 5000XL in the UK is at Howard Hunt in Dartford, which installed its system in March last year and has been working it up to handle personalised ‘white paper’ direct mail. A 5000XL at Servinform Group in Spain is the only other announced European sale, but this was deemed unsuited to its planned application and has been taken out again. Issues over availability of compatible papers at acceptable prices seem to be holding back European sales, so North America and Japan have the highest population of 5000XLs so far. However, the monochrome Prosper 1000 is selling well into Europe and the UK, mainly for on-demand book work.

The Howard Hunt press officially still remains a ‘Beta’ installation, meaning among other things that the company hasn’t paid the full price yet. However Will Mansfield, Kodak’s worldwide marketing director for inkjet printing solutions, said that the DST press will count as a full commercial installation once it is fully commissioned. He wasn’t able to put a target date on this commissioning.

Mr Dixon also announced that a second Ricoh InfoPrint 5000, a narrower and somewhat slower 520 mm inkjet colour web press, is also now operating at the Dagenham site. The first one was installed four years ago and work has increased to justify the second one, according to Fraser Church, DST’s head of

marketing.

Used together with intelligent stitching lines, the InfoPrint press are used to produce personalised multi-element Intelligent Investment Statements for the financial services sector.

DST’s various plants in the UK and North America have long been users of Kodak’s Versamark presses and overprint heads, said Mr Mansfield. The DST Bristol site already has two Versamark presses. Another fast digital press will go there as as part of an expansion programme into ‘white paper’ transactional printing facilities at the Bristol site, which will also entail an expansion of enclosing capacity by 29% and an enlargement of the factory area by 2400 m2.

The DST Output Solutions name was applied to all the print activities of the group in June this year, reflecting the name of the parent company, DST inc in Kansas City, Missouri. The data services, customer engagement and creative services activities are called Lateral Group.

Previously the company had been called Innovative Output Solutions (IOS) which in turn had come out of a 2010 merger between DST and the former DSICMM. It currently has UK sites in Bristol, Dagenham, Jarrow, Nottingham and Peterborough. However, it closed the K2 direct mail print site in Openshaw, Manchester, during the summer.

‘While we have been changing the name above the door and re-aligning Lateral Group as a customer engagement agency, in the UK and North America, we have also been investing in our infrastructure, service offering and personnel,’ Mr Dixon said.

‘Combined, these will provide our clients with the necessary tools and environment to create more engaging and effective communication both now and in the future.’

Contact: www.graphics.kodak.com and www.dstoutput.co.uk