Michael Todd with the Truepress JetSX in situ at RCS.

Europe’s first Screen Truepress JetSX, a B2 format sheetfed inkjet press, has been installed at RCS in Retford, Nottinghamshire.

Managing director Michael Todd said it will be used primarily to print on a range of personalised packaging that the company is developing. He called it ‘a game changer for the business, a compelling and unique product that opens the door to more specialised applications and more rewarding business opportunities.’

RCS offers a wide ranging choice of printed products through a network of resellers such as copy shops, printers as well as to print buyers and designers. It expects to turn over about £7.5 million this year and employs more than 100 people.

Mr Todd says that the primary reason for choosing the Screen press was its ability to print onto heavy substrates including carton boards up to 600 microns. RCS is developing a range of pre-creased and perforated products that can be produced in advance as blanks and held in storage until an order comes in. These are going into the next edition of the company’s catalogue, which goes out to its resellers and on its website.

It would then be a quick and easy matter to print onto these in very small quantities on the new inkjet press, down to one-offs, ready for same-day despatch if needed. ‘The press then becomes in effect the finishing process,’ said Mr Todd.

He cited likely examples of such personalised packaging: ‘Say you have a conference and you want to produce personalised delegate folders. You can’t do those in B3 so the B2 format is needed. Or you might want to produce personalised boxes for bottles and other gifts.’

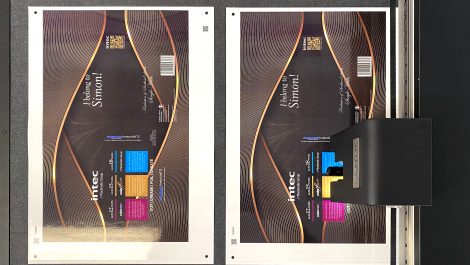

To demonstrate what the Truepress/Scodix pairing is capable of, RCS will send a free personalised sheet to the first 2000 people in the UK who request one. Go to www.rcs.plc.uk/freebie.

Among the other features of the JetSX that impressed RCS were the variety of media the press can handle and the precision vacuum flat-bed paper transport mechanism, which is the same as used on offset presses. Mr Todd said: ‘The straight feed means we can print on stock up to 600 micron thickness without bending it, which produces perfect print because the ink is always jetted from the optimum vertical position.’

The SRA3 format that’s common in earlier digital presses is too restrictive for packaging, he felt. Also, it fits the company’s existing workflow, especially its cutting and creasing machines, which are converted flatbed cylinder presses. ‘The fact that the press is compatible with B2 and B3 stocks mean it fits easily with our folders, binders, laminators, and so on, and because the ink dries virtually instantly we can go to finishing almost immediately after printing.’

RCS has something of a track record of ordering the first examples of equipment in the UK. In 2010 it was the first to put in the Scodix raised-image digital UV varnishing inkjet, while over the past summer it installed the UK’s first Presstek 75DI, a B2 format digitally imaged offset press. The company already has a Xeikon 5000 roll fed digital press that can handle similar B2 formats, but Mr Todd said it isn’t suitable for the short run packaging work planned for the JetSX. ‘It can only handle weights up to 350 g/m2. Also, the Screen prints are very similar to offset, except they are dry and ready to go after printing. With a toner press you get issues with wrinkles due to differential heating in the fuser.’

‘The Truepress JetSX lifts digital quality and flexibility to a new level,’ added Mr Todd. ‘It is the only B2 inkjet press that can print onto pre-scored and pre-creased boards which allows us to produce dozens of web to print packaging solutions very efficiently and extremely competitively. In combination with the finishes possible with the Scodix 1200, the press is perfect for producing premium personalised and promotional print and gifts, such as playing cards, books and packaging.’

The Screen Truepress JetSX was originally announced at drupa 2008 and was pronounced ready for shipping at drupa 2012, where the ability to print on 600 micron board was introduced for the first time. The list price is about £1.2 million, although Mr Todd wasn’t willing to confirm the actual figure that RCS will be paying. ‘The point is more what we can do with it,’ he said.

Although conceding that the same sort of money would buy a well specified offset press that would run a lot faster than the Screen press (quoted as 1620 B2 simplex sheets per hour, or 810 duplex), he said that wasn’t the point as he’s already got offset presses and doesn’t need another one.

You can’t do one-offs on a Speedmaster,’ he pointed out. ‘The offset market is over-capacity and people are having to cut prices to get the business, which is what we don’t want. If we think that personalised packaging has huge potential then it’s better to be early into the market than to be an also-ran later. This way we’re going into a rarefied market where supply doesn’t outstrip demand.’

He added that he’d also considered the B2 format HP Indigo 10000 press announced earlier this year. ‘However, the Indigo is only just in beta testing now, whereas the Screen press is a production ready machine. The Indigo won’t handle the heavier stocks that we wanted either.’

Kees Mulder, president of Screen Europe, said that RCS is ‘the perfect home for Europe’s first Truepress JetSX. The response to the press has been especially positive among print providers who recognise that focusing on value-added, premium-quality work is the way to success and profitability. Many of these are established offset producers making a strategic move into digital and looking for a productive machine that not only matches offset for quality but also fits into their existing workflow.’

Contact: www.screeneurope.com and www.rcs.plc.uk