Heidelberg’s new 4D printing technology is a new direction for the company.

Three years after becoming a reseller for Ricoh’s SRA3 toner engines, Heidelberg has announced its plans for the wider digital print world, with inkjet leading the way.

The company gave a ‘Digital Sneak Peek’ to journalists at the start of April – an event that was both interesting and revealing in terms of the rhetoric and the directions this new digital strategy will take.

Dr Gerold Linzbach, the company’s chief executive, set the tone with the following words: ‘In order to enter the digital arena we had to get much more focused. We are much more humble now and more understanding that other companies have solutions that can help customers. For what we want to achieve in this area it is necessary. We have changed our target portfolios, and changed how we approach partners.’

Such humility was accompanied by a very public throwing in of Heidelberg’s lot with inkjet as the key digital technology moving forward (although it also said it was ‘excited’ about the next generation of Ricoh dry toner engines coming through). In the pipeline are a number of new inkjet developments: right now it already has a technology it is calling ‘4D printing’ – a direct to object inkjet system called Jetmaster Dimension, that can be used on anything from small household products all the way up to cars and even airplanes; it is working with Gallus and Fujifilm on a new narrow web hybrid flexo/digital label press; and further ahead, Heidelberg raised the prospect of a sheetfed inkjet press in formats up to B1 for commercial and packaging markets. It also said that any potential partnership with Landa will be addressed when there is a working technology to partner with.

At the Sneak Peek, journalists were shown around Heidelberg’s research & development facility in Germany, with first stop being a Fuji JetPress 720 inkjet machine, which it is using for testing purposes. Heidelberg considers this to be capable of the highest inkjet quality in the market (1200 x 1200 dpi). Jason Oliver, head of the digital business area, commented that ‘it has started to change how people in Heidelberg think about digital and inkjet; it is really the first proof in a single pass that inkjet quality can match the needs of our customers in commercial and packaging print’.

While Heidelberg is not selling the JetPress 720, it is using the engine to test and experiment with inkjet heads, ink formulae and substrates – research that will inform the company’s inkjet products to come.

Next was the proposed hybrid flexo/inkjet label press, which it is developing with narrow web label printing specialist Gallus and the Fujifilm heads. Digital print accounts for only about 5% of labels produced worldwide and with other digital label presses there have been compromises in speed and colour gamut, resulting in sometimes a second pass being required. ‘The growth potential is significant for a press with no compromise. That is this press. It will offer the quality of offset, the speed of flexo and the efficiency of digital,’ the company claimed.

There wasn’t much to look at – just the Gallus ECS 340 platform (340 mm web width) and an empty box with peep holes for visitors to see an artist’s impression of what the press will look like when the inkjet heads are integrated. Nevertheless, Heidelberg hopes to have a product (though not necessarily a prototype) on show at Labelexpo in September.

The company’s ambitions extend beyond labels for inkjet, with a mooted range of sheetfed inkjet presses up to B1 format on the drawing board for the commercial and packaging market. ‘What the market wants is volume between 250 and 2000 sheets, printed both sides for commercial, one side packaging. It has to be faster than today’s machines or it will not make economic sense. Quality is a given and 1000 sheets has to be a bit cheaper than today,’ said Mr Oliver. Heidelberg intends to ‘move inkjet into the mainstream’ it said, and added that with the rate at which inkjet is improving in many facets, ‘the time to capitalise is right now’.

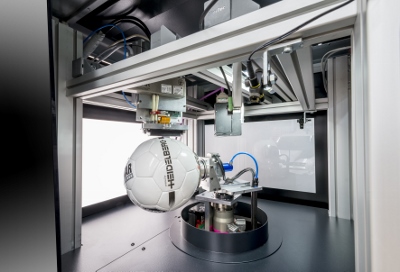

The sheetfed products seem some way off, with the company openly admitting that the label press and its new 4D printing concept come first. This last was shown as a product called the Jetmaster Dimension, printing on the sides of footballs – which is in fact the application that its first customer, flyeralarm in Germany, will use it for.

Here in fact is a brand new direction for Heidelberg – making use of the non-contact nature of inkjet to print direct to any 3D object, from the massive down to the small, to tolerances of one tenth of a millimetre. It uses a combination of advanced inkjet, high precision robotics, UV curing and workflow. There are two main markets for this: personalising mass produced consumer goods; and bringing more automation and productivity to decorating goods in the industrial process.

It would not say who its partners for the robotics were, and in fact the inkjet heads will not necessarily be Fujifilm’s, since flyeralarm’s Jetmaster Dimension uses Xaar heads. Clearly, 4D printing systems will be built for the specific needs of a customer, the set up needed to print onto a football or a bottle, being considerably different to that for a car.

And what of the toner-based digital printers, the Linoprints that Ricoh manufactures for Heidelberg – where do they fit in with all this digital activity? ‘We are very excited about the next range of products coming from Ricoh,’ said Mr Oliver. ‘Ricoh is focused on making the technology faster, better and cheaper.’

It said that it is looking into Ricoh’s refurbishment activity with these presses, since the first generation are reaching that stage in their lifecycles.

Ultimately, the impression was one of a Heidelberg that is undergoing significant change, and reaching out to industry partners in ways that will take some getting used to for those that always believed the company had all the answers itself.

Clearly, as Jason Oliver’s words in his presentation showed, this is no longer the case. He said: ‘Heidelberg will be successful in digital for three reasons: we have the world’s best customers and many of them want Heidelberg to grow and expand in digital; we understand printing and business processes and the technology that ties them together; and we have finally opened our hearts and minds to partners that will lead to the right business solutions.’