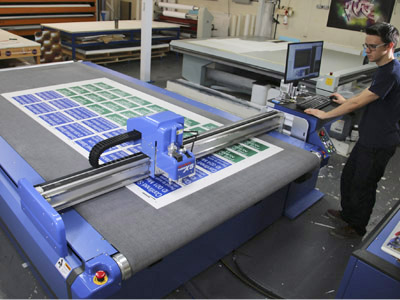

Hotel safety signage being cut on GB4’s DYSS X5

To solve a bottleneck caused by hand cutting, Graphics4 Business purchased a DYSS X5 digital cutting table from AG/CAD.

‘We bought an Océ Arizona XT flatbed printer four years ago and this meant we had three printers in operation,’ explained Ian Hatfield, owner and director of Worcester-based GB4, which employs aqueous, solvent and large format UV flatbed digital printing to manufacture exhibition graphics, signage, pop-up systems and banner stands, vinyl, fabrication, PoS, fabric and flag production.

‘These machines all fed in to a bottleneck that was our manual hand-cutting operation,’ continued Mr Hatfield. ‘Added to this, the flatbed enabled us to print foamex, foam board, cardboard, Corex, PVC and much more. These materials brought greater challenges when conducting precision hand cutting.’

With a 3 m cutting area on the Océ Arizona, G4B opted for a 3 m x 1.6 m DYSS X5-1630 with a roll feeding conveyor facility and installed the digital cutter last September.

‘The DYSS churns through the creasing, marking and cutting and the printers are now the bottleneck – they can’t keep up with the DYSS; a complete role reversal,’ said Mr Hatfield. ‘The DYSS is easily giving us a 300 to 400% time saving and this is regardless of the job.’

The DYSS X5 has also absorbed some of the capacity from the company’s dedicated CNC routing machine to process some of the tough boards and materials that could often cause a bottleneck.

‘We can now generate complex forms and shapes with exceptional precision and speed,’ noted Mr Hatfield. ‘This has already enabled us to win new business producing short-run boxes for customers.’