Fespa’s return to schedule – and form – at the end of May saw a show bustling with activity and interest as the wide-format world reconvened. Michael Walker was there and presents some highlights.

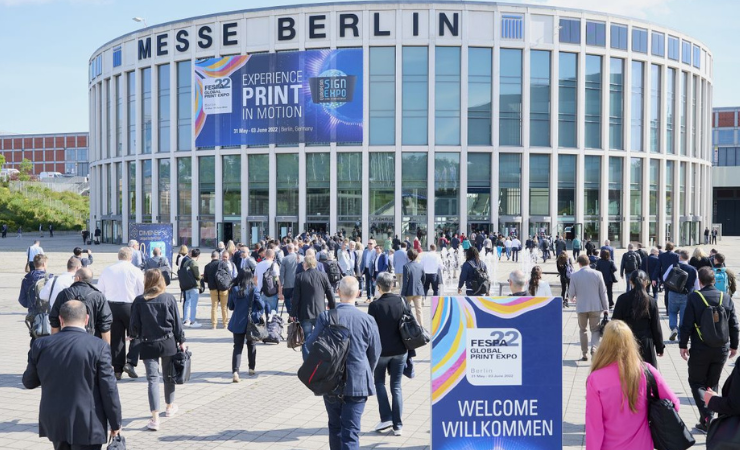

Although Fespa did manage to put on a show in October 2021 in Amsterdam, after several postponements and reschedulings, it wasn’t that busy with either exhibitors or visitors because of the ongoing pandemic restrictions. This year’s event, however, very much felt like ‘the real thing’ and saw eight halls in the Berlin Messe filled with hundreds of exhibitors.

At the time of writing, just after the show closed, official attendance figures hadn’t been released, but footfall seemed as good as in the ‘old’ (pre-pandemic) days, with visitors of many nationalities.

It was clear that this part of the print industry, which has arguably been hit harder than most by lockdowns and restrictions on in-person events, was keen to put that period firmly in the past and get back to its own socialising and in-person selling. And there was plenty for everyone to look at, with new and updated machines, materials and software vying for attention.

Perhaps most fundamental to digital print is the PDF family of standards and the Adobe PDF Print Engine (APPE) technology that is used by many printer, Rip and DFE manufacturers to render digital files into ink or toner dots. Adobe used Fespa as the platform to launch APPE 6.0, introducing capabilities specifically designed to address expanded colour gamut (ECG) printing, support for spectral brand colours, and features that address finishing requirements.

ECG support, which is principally aimed at both digital and analogue packaging applications, but also supporting any ‘CMYK-plus’ print engine, allows for direct colour conversion of page elements from source colour to the target seven-colour or other output space in a single step, avoiding gamut losses caused by intermediate CMYK-only conversion and cumulative rounding errors introduced by two-stage conversion.

Support for spectral brand colours is intended to provide absolute values for colours and so avoid possible misinterpretation. Speaking to Digital Printer, Adobe’s Mark Lewiecki noted that some Rip and colour management vendors had already added spectral colour support via other means but this move now makes spectral colours ‘first class citizens’. More sophisticated image resampling algorithms from Photoshop have now been implemented, replacing relatively ‘primitive’ approaches in previous APPE versions.

Support for automated post-press processes such as cutting and creasing, often achieved by assigning spot colours in vector artwork has also been added via the introduction of ‘reserved names’. This allows the Rip to exclude them from trapping, transparency flattening or knock-out calculations, while allowing on-screen previewing and proofing, and maintaining integrity with the print artwork.

This capability also has implications for ‘derived’ plates or planes – additional colour separations that can be automatically generated from artwork, to provide a white underlay for printing on coloured substrates, for example, or producing a digital spot gloss varnish overlay. This

capability can also handle production-specific issues like choking a white underlay in DtG printing.

Another major announcement at the show was the conclusion of Agfa’s purchase of Inca Digital. Pascal Juéry, president and CEO of the Agfa-Gevaert Group, described the move as ‘a demonstration of our willingness to grow the business. We needed to accelerate, to get new scale, and new capabilities in the toolbox,’ he said, adding that ‘the Inca acquisition is a perfect example of the reinvention of Agfa in digital imaging’.

Vincent Wille, president of Agfa’s Digital Print and Chemicals division, explained that Inca firstly brings complementary product capabilities in Inca’s historic main markets, with bigger and faster multi-pass machines, ‘a nice add-on’, and secondly and perhaps more indicative of the planned direction of development, ‘a platform for growth inindustrial print with a focus on packaging and single-pass’.

Inca CEO/CTO Stephen Wilson showed how the Inca range added to the top end of Agfa’s range in performance terms, with the Onset X, SpeedSet and the Print Engine, its ‘super high-end’ co-development for corrugated with BHS. Mr Wille noted that applications in cartons and corrugated would be targeted due to the fast growth for digital in these sectors, where Agfa would now be able to offer full solutions.

Mr Wilson reported that Agfa inks were already being run on Inca printers at the company’s Cambridge, UK site, giving the installed base a choice that might ‘open eyes and opportunities’. Ongoing support arrangements will vary by country. It appears that customers who bought through Fujifilm and who continue to use

Fujifilm inks will also be supported by Fujifilm but backed by Inca as previously; what would happen if they then switched to Agfa inks ‘would have to be considered carefully’, Mr Wilson told Digital Printer.

Sales will mostly continue to be direct in the major geographic markets, and the SpeedSet even more so. Mr Wilson said that ‘it is easier to sell through the merged business. There are so many opportunities, we have to carefully prioritise.’

High speed printer developments were also announced by EFI, which confirmed the commercial availability of the super high speed Nozomi 18000+ single-pass printer for display graphics. The Nozomi 18000+ LED is a 1.8m width single-pass printer designed for the sign and display graphics market, based on the technologies in the corrugated printer of the same name. EFI claims that at up to 1000 sheets or 1.2 x 1.4m boards per hour, equivalent to between 3000 and 5000sqm/ hr, it is three to five times faster than scanning head alternatives and can handle both synthetic and paperbased media.

Announced in 2021, the 18000+ offers manual or fully automated feeding and stacking, a hybrid aqueous/UV primer for difficult materials, and optional pre-white coating for reflective or coloured substrates and/or post UV coating for durability and weather protection. EFI contends that its ‘unparalleled throughput helps users drive profitability in a wide range of high-volume signage applications’.

That argument seems to have been taken on board at Delta Group, which has ordered the new press for delivery in the third quarter of 2022, making it the second customer site for the 18000+ and the first outside North America.

A preview was given at Fespa of the EFI Reggiani EcoTerra, a new all-in-one ‘eco-friendly’ pigment-based textile roll printer that requires neither pre- nor post-treatment for the fabrics it prints, thus reducing its footprint, energy and water usage.

The EcoTerra offers a seven-colour ink set (CMYK plus blue, red and green) for expanded colour gamut and is claimed to achieve excellent wet and dry colour fastness with sharp detail and high durability. An enhanced polymerisation and finishing unit is said to give a softer hand feel to finished printed fabrics. An analytics application, Query, for monitoring and reporting, is also in development, and Reggiani demonstrated a partnership with textile Rip software developer Inèdit at the show.

Introducing brand-new printers and others that hadn’t previously been shown in public, was Fujifilm, which launched two new wide-format printers, the Acuity Prime L, and the Acuity Ultra Hybrid, the former adding a 3.2 x 2m flatbed option to the existing Prime range and the latter marking the company’s first high-performance hybrid option.

The Acuity Ultra Hybrid is a 3.3m printer that offers speeds of up to 218sqm/hr on flexible media though less on rigid substrates. Print resolution is up to 1200 x 1200dpi and Fujifilm says that the machine combines ‘ultra-high’ quality for ‘near photographic’ interior graphics with a competitive return on investment. A dimpled table surface is said to support a wide range of media types, with protection against accidental damage and accurate media feed. This is complemented by an intelligent vacuum control system that adjusts to the loaded media width and adjusts vacuum strength to hold it down securely.

The Acuity Prime L complements the Prime 20 and 30 models introduced last summer and offers up to 202sqm/ hr thanks to a larger bed size. It uses the same carriage and Ricoh Gen 5 printheads as its smaller siblings, with six vacuum zones and 16 media location pins, plus the ability to print side-by-side jobs with a dual zone function. The Prime L supports up to seven ink channels (CMYK, plus white, clear and primer). It uses Uvijet HM inks, said to yield excellent adhesion to a broad range of substrates while also producing a wide colour gamut. This is augmented by a new jettable primer for particularly difficult substrates. Both new printers are currently in beta testing and will be available in autumn 2022.

Canon also had a new flatbed printer, the Arizona 6100 MkII, a 2.5 x 3m model intended for high volume production environments. It prints at up to 220sqm/hr and is offered in two variants: the XTS is aimed at a wide range of display media types and features independent control of vacuum zones, allowing simultaneous printing of multiple boards, unusual shapes or staggered loading for continuous printing; the XTHF has 15 times the vacuum power and for porous materials such as corrugated board or warped media. Both machines are available in six- or seven-colour versions and support communications with MIS, production analysis tools or robot automation systems.

The Colorado line of UV-gel roll-fed printers already offered a choice of matte and glossy finish, but previously the same choice had to apply to the entire job. With the introduction of FLXfinish+, it is possible to mix both finishes within a job in a single pass, to achieve creative effects of some

complexity and with an appearance not dissimilar to spot gloss UV, but without the extra process or consumable of digital embellishment systems. The new capability will be included as standard on all Colorado 1650 models and offered as an option on the entry-level 1630. It will also be available as an upgrade.

On the software side, the Prisma XL Suite is intended to automate production of complex jobs and to maximise printer uptime. PrismaGuide XL is a design and job automation application that simplifies preparation of jobs, storing them for re-use. The Prisma remote app allows Colorado printers to be monitored from anywhere, while PrismaService is a cloud-based platform for customer

Durst also expanded its printer family with the introduction of the five-metre P5 500, whose development goal was reliability for unattended operation. The P5 500 features an integrated mesh printing kit that can simply be switched in or out to suit different material types, a two-minute process compared to a two-operator 15-minute one on the previous model.

The new printer also features double-sided printing and gains a horizontal cutting capability in addition to the vertical slitter; its 5.25m width can accommodate two 2.5m rolls or three 1.6m ones; horizontal cuts can be made without stopping printing. No cut marks are required on the printed roll(s) as the position is calculated via encoder, though the double-sided printing does allow for QR codes to be printed to aid job identification.

The P5 500 supports eight channels at up to 1200dpi, which may be used to add light inks, white or clear varnish, or for double CMYK for maximum productivity. The new P5 ‘Double 4’ configuration option also allows a second set of printheads to be added to the P5 210/HS and 350/HS models, doubling their productivity.

A new top-of-the-range model was introduced by swissQprint, the Kudu flatbed – see news, page 8. SAi premiered Flexi 22, its sign-making, print-and-cut Rip software, adding productivity and workflow features. A new feature is order snapshots, a way of capturing settings and files for specific jobs that simplifies repeat orders.

New production-focused capabilities enable cutting path generation from supplied files without needing access to the original artwork-creating application.

Flexi can open and edit files created in Adobe Illustrator or Corel Draw to add contour cut lines, or these can be auto-generated from bitmap files. DtF/DtG tools enable the automatic generation of white under-layers for printing colours on dark fabrics, as well as support for solid white elements or knock-outs. Colour ways for textile or wallpaper designs can also be edited without access to original artwork files.

Artwork for very large projects, such as bus wraps, can be created and worked on at actual size. True shape nesting has been improved and is said to allow media savings of up to 20-30%. A new dashboard allows users to keep track of and manage their software subscriptions and software updates, as well as to monitor production and usage of consumables.

Meanwhile Onyx 22 brings a range of ‘everyday automation’ features to improve productivity. The new release implements a drag-and-drop interface to allow job files to be added to the queue with job parameters set automatically. This is complemented by Smart Job Submission, in which key job attributes can be embedded in the artwork file name, again automating processing and set-up for less skilled operators. There’s a defined file naming syntax for this and parameters that can be set this way include the job, customer, size and number of copies. Preparing work for flatbed output or DtG printers is also supported via auto-placing of artwork elements to match jigs, and repeated elements in artwork can be split to enable shape-based nesting. Colour matching is aided by the addition of a Color Reference Library, the ability to generate and print swatch sheets with calculated delta-E values; these can be measured for iterative refinement, if required. Specific colour settings for textile printing applications are now supported too