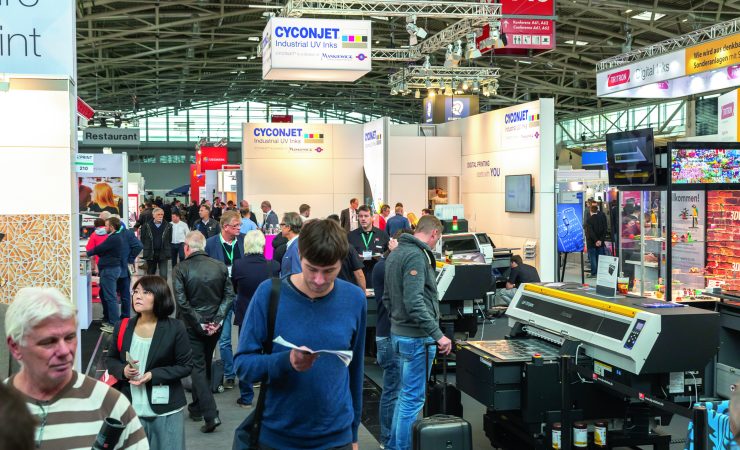

The InPrint show is back after an enforced absence, showcasing digital printing technology developments, particularly around inkjet.

InPrint describes itself as ‘Europe’s flagship event … for the emerging community of printing professionals and manufacturers who want to maximise on new business potential for print applications in the industrial production sector’ and so targets not just print industry people, but professionals from a range of manufacturing and related industries. After an pandemic-enforced break in 2021, the show is back this year, running concurrently with ICE Europe and CCE International which respectively cover paper, film and foil converting and corrugated and folding carton production, so the three collectively cover a wide gamut of packaging and industrial print applications.

Patrick Herman, event director for the Converting, Paper and Print Events at organiser Mack-Brooks Exhibitions, says, ‘For the first time, the three shows will take place at the same time and the same venue creating an all-round experience with increased opportunities and synergies for all trade visitors on-site. With InPrint Munich covering the print technology for industrial manufacturing we are now able to offer an almost comprehensive overview of the value chain.’

The InPrint exhibition is complemented by a conference programme that explores technology trends, market developments, new applications and innovative projects as well as the latest product and technology developments. Here are some exhibitor highlights:

Global Graphics will present its SmartDFE, a software and hardware solution that allows print to be added in industrial production environments. Combining the specialist capabilities of the various Hybrid Software Group companies, SmartDFE supports Industry 4.0 telematics, MIS integration and connectivity with automated manufacturing lines via OPC UA. Via the company’s Harlequin Direct technology, SmartDFE can also send print data directly to the printheads at the ‘blistering speeds’ needed for high volume single-pass inkjet systems.

The technologies displayed at InPrint have a wide range of applications

Global Inkjet Systems (GIS) will present its Atlas IQ Tools for image optimisation for digital print which also compensate for a variety of inkjet quality issues. Its ink/fluid delivery systems, which have high resistance to aggressive fluids to support extended materials deposition, will also be featured, along with the company’s capabilities in drive electronics supporting major printhead manufacturers’ models and an increasing range of industrial applications.

Slovenian manufacturer INO builds printing systems that combine the strengths of screen and digital printing which it says offer high output with minimal setup time via automated processes. Described as user friendly at ‘all operation levels’, the INO machines offer the convenience of a single supplier and a return on investment in ‘the shortest period’.

UK-based Integration Technology specialises in UV LED and other UV lamp implementations across various print sectors and has been involved with this technology since its earliest days. The company has recently made two new appointments to pursue growth in 2022, with Neil Stickland joining as marketing manager and Jamie Fenn as sales and business development manager. Each brings around a decade of relevant experience.

Ipco makes steel processing and conveying belts and will use InPrint to present findings that belt vibration – which can affect imaging quality – is between three and six times lower with steel designs than with plastic alternatives. On 17 March global product manager Cherryleen Garcia-Lindgren will present the results of independent research carried out by the Fraunhofer Institute. The company says its belts are suitable for applications ranging from large format corrugated packaging to furniture board, film wrap and ceramic tiles.

Meteor Inkjet, which develops control electronics and printhead subsystems for a wide range of inkjet applications, announced last summer that it is now working with Epson’s T3200, T1600 and D3000 printheads. Applications for the first two include signage and product packaging, while the latter has a positioning capability that reduces assembly time in multi-head arrays. Meteor has also significantly increased its floorspace at its Cambridge, UK headquarters, reflecting strong growth.

Nazdar produces UV, water- and solvent-based inks for inkjet and other printing technologies. It will demonstrate labels and packaging applications but will also discuss a range of industrial applications including textile, graphics, direct-to-shape, 3D and commercial print, as well as special effects with functional clear inks and varnishes. There will be a focus on OEM and system integration business, based around the company’s relationships with various print equipment and printhead manufacturers.

Customised inks for personalised packaging and labels will also be the focus of the Siegwerk stand at InPrint, including UV and water-based types as well as primers and OPVs for a wide spectrum of substrates.

A similar portfolio will be presented by newcomer to the show Zschimmer & Schwarz, which offers tailored solutions for primers, overprint varnishes and pigment inks for inkjet across a range of substrates including ceramics, textiles, technical glass and papers.

Xaar will showcase its array of inkjet technologies, printheads, electronics, data paths, system components and ink supply systems, as well as its expertise in designing systems to deliver ‘difficult’ fluids to a range of substrates and in multiple orientations. As a sponsor of the conference programme, general manager of the printhead business unit Graham Tweedale will present an overview of the company’s core technologies and the capabilities of the ImagineX printhead platform.