The fashion industry is embracing digital print, but how is each new wave of designers introduced to the technology? Charlie Kortens sat down with Northumbria University’s Kenny Macrae to find out

Kenny Macrae has more than 30 years of experience when it comes to fashion and design, having originally studied at Edinburgh College of Art in his native Scotland. By his own admission Mr Macrae ended up at Northumbria University pretty much by accident. ‘I arrived in Newcastle inadvertently,’ he says, ‘I came down to help a friend who was teaching at the university… but after 22 years I’m still here!’

Over the course of those two and a bit decades Mr Macrae has risen to the point where he is now technical manager for fashion and textiles, responsible for managing the technical provision within all areas of the faculty of Art, Design and Social Science. But despite spending so long at an institute of higher learning Mr Macrae is far from a dusty academic. ‘My passions and skills have always leant themselves to the actual work rather than just pure design,’ he tells Digital Textile Printer. ‘I like to get my hands dirty!’

This attitude means he is intimately familiar with the many different ways students might create work, including digital printing. ‘My first experience of digital was a Mimaki TX1 which Edinburgh College of art installed shortly before I left,’ he explains. ‘That was for wide-format work and I remember when I first saw colour separation done at the push of a button, it was just jaw dropping. Prior to the Mimaki’s arrival everything had to be done by hand.’

After this, digital took a back seat in Mr Macrae’s career until he arrived in Newcastle to find another Mimaki machine, a TX 1600, waiting for him. This early experience of Mimaki tech has built some brand loyalty in Mr Macrae, whose department recently upgraded to a TX3. ‘The first digital printer I ever used was a Mimaki and their equipment has always proved reliable,’ he explains. ‘I’ve also known Magnus (Magnus Mighall of Mimaki partner RA Smart) for the best part of 30 years. We have an incredibly strong working relationship so I trust his advice as well.’

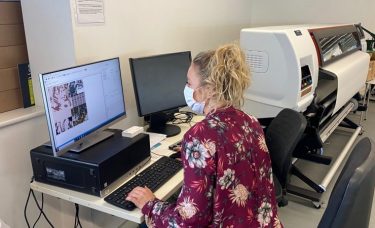

Fashion students have managed to keep working during the pandemic, largely thanks to digital printing technology

A Stitch on Tyne

In 2020 Mr Macrae welcomed an HP Stitch S300 to Tyneside in his first foray into dye-sublimation printing, which he says has significantly enhanced what his department can offer.

Installed by RA Smart, the machine was first put into use as the first lockdown came to an end in England and Mr Macrae says it has gone on to play a key role in helping students to keep working even as access to facilities has remained limited. Initially intended to increase the department’s textile offering to non-specialist students, the Stitch has actually gone on to play a much wider role, being used by Masters students for work in sportswear as well as sustainable and ethical fashion.

‘Thanks to HP PrintOS our students were able to electronically send us work to be printed out and transferred onto fabric,’ Mr Macrae tells. ‘We would send the finished article back to them and – in conjunction with half-scale mannequins we provided the students with to allow them to engage with the blended learning over lockdown – undergraduates were able to develop their garment shapes, silhouettes and print designs from the safety of their own homes.

‘The printer is seen as something that will become integral not only to fashion students but as a resource for the whole of the design school. The speed, efficiency and simplicity of the printing process means that eventually anyone from the school should be able to utilise it. It allows students to be experimental and develop their samples and ideas with a minimum of waste and allows us to move from small samples to full sized garment prints easily.

‘From interior design students wanting samples for soft furnishings, to fashion students looking to push the boundaries of print through fabrication, it will allow everyone to prove concepts and realise their ideas. It’s not a machine that has been brought in to replace traditional skills and practise that sits at the core of what we do, but instead a modern printer that will help enhance our output and allow our staff and students to push the boundaries of print design and research within their chosen discipline.’

Northumbria University’s he HP Stitch S300, installed in 2020

The next generation

Obviously it’s these students, the next generation of designers, that are key. When it comes to digital printing Mr Macrae says that there can often be a ‘bit of a learning curve for students in the sense that they don’t necessarily know what sort of kit is available and what different pieces of kit can do. But in more general terms, digital technology is just part of the modern world. We have modules focusing on digital design and digital illustration and we’re a fashion course so everything we do is geared toward fashion… everything relates back to garments and portfolio work.

‘We do have students who specialise and go a bit more into depth in terms of process and how samples are produced and I think most art colleges would now say that their digital provision is more or less in line with more traditional skills… though I don’t think we should ever get to the stage where either option works at a detriment to the other.’

The advantages of digital printing are many, though Mr Macrae says that at his university ‘I advocate using digital print as a starting point. There are huge speed advantages, particularly with dye sublimation printing which is borderline instant, but I encourage students not to see it as the be all and end all.

‘Those students that aren’t specialists make use of it because it’s quick, but I think that specialists are hard pushed to find something to replace screen printing or traditional hand dyeing in terms of aesthetics, the depth of colour, the ability to mix up substrates… there are other options which give you an extra level of depth that digital, for me at least, still lacks.’

When it comes to the substrates he talks about, there is certainly creativity on display amongst his students. ‘We have our Mimaki set up with reactive inks,’ Mr Macrae explains, ‘so students tend to be printing on your cotton and silk type fabrics… it’s a bit more restrictive because those fabrics need to be coated before they go through the machine. But for dye sublimation work, I personally advocate whacking anything through and seeing what happens!

‘We have a set of rules and guidelines regarding what to do and what works, but the really interesting things tend to happen when you push against those boundaries.’

When he says whacking anything through, Mr Macrae really does mean anything, particularly for work that can be printed onto sublimation papers and then put through a heat press rather than being printed directly onto the fabric. ‘I think that in terms of sourcing materials it’s very much about finding out what will happen if you try this fabric or that fabric, or a coloured background versus a pale background and all these sorts of things… A lot of that is driven by students, they’ll source media from anywhere, you’ve got no idea!’

This ingenuity isn’t just limited to substrates either. ‘We’re very creative and it’s very much a sample driven culture here,’ Mr Macrae adds. ‘Students might employ embroidery (done by hand or machine) or other forms of embellishment, but we also try experimental things… what happens if you melt a plastic bag onto your work? What will it turn out like if you shred it and then weave it all back together? We’re only limited by our imagination.’

Mr Macrae says that Northumbria University has ‘s sample driven culture.’

Breaking through

Of course the students eventually move on from the university, looking to forge a successful career in fashion. Digital Textile Printer asked if the proliferation of ecommerce platforms and affordable entry-level textile printers would make it easier for fledgling designers to set up their own businesses or labels.

‘It’s not as simple as that,’ Mr Macrae insists. ‘I’ve been a designer for more than 30 years and I still sell my own work, I know it isn’t easy. There is a place for the sort of thing you’ve described but I think that in fashion you need some sort of initial financial backing else you’ll struggle to get to that stage where you’re stable and can pay a mortgage.

‘I do agree that as the technology gets cheaper you will get more people supplementing their income, but people can produce T-shirts and make use of direct-to-garment printing without a huge amount of start-up capital already. Its not easy to go from a standing start to shifting more than 500 products a week, 3D printers have fallen dramatically in price in recent years, and you can set up one in your garage now, but it’s a huge leap from that to establishing a viable business.’

Considering his decades of experience working in design, as well as his familiarity with the printing process, Mr Macrae is perfectly placed to comment on whether digital print is doing enough to sell itself to the design world. ‘I think there is a fair criticism to be made,’ he says. ‘There is still a something of a dividing line between ‘the creative people’ and the printers. Print is more geared toward production and output, like a factory.

‘These days there are smaller machines and user-friendly platforms, but a designer often still needs that input to see how to turn their idea or sample into a finished product. They’ll need the advice on the best technique and the most effective way to get that bang for their buck.

‘Here we have lots of contact with actual designers, but we don’t have anywhere near as much with printing manufacturers, suppliers or the people who can actually make things happen! A lot of it is down to visibility, we do get reps from fabric companies coming in and chatting to students about their products, but it’s very unusual for us to be approached by someone like HP for instance. I’ve been to the showrooms and the exhibitions and for certain students it would absolutely be beneficial to have that contact and that relationship, maybe its something both sides should look to develop in the future.

‘I’d recommend visits that would let students see the context of their work, rather than handing over a template and coming back a day later and to see something that has been done for them… actually seeing the machines in action and understanding how their digital file actually becomes an end product.’

With the advantages that digital can offer, from print quality to the ability to personalise, producing short runs to environmental benefits, matching up perfectly with trends developing in the fashion world, anything that leads to closer collaboration between the two sectors is surely worth a shot?