If you want a truly metallic look on your printed materials, then you have to use real metal. There are various different processes for achieving this in digital print. Simon Eccles goes prospecting.

There are three ways to get more metal into your print: it can be mixed as flakes into the ink or toner that forms the image, used underneath the image as a silver or metallised layer on a substrate, or applied on top as a foil made of microscopically thin metal. All three ways demand very different techniques and processes, and give different results.

Metallic-er

A metallic substrate may be a board or paper pre-printed with silver ink, or it may be a metallised plastic layer (usually polyester) applied as a laminate onto paper or board.

Unlike printed ink, a highly reflective near-mirror finish is possible from metallised plastic, as well as various diffraction and holographic effects. Some digital processes are happier with plastics than others. HP Indigos can do it, and so can UV inkjets, whether the wide-format type, or the little ‘baby flatbeds’ available from Mimaki, Mutoh and Roland. UV inks are used by the Konica Minolta and Komori B2 inkjet presses sold respectively as the AccurioJet KM-1 and Impremia IS29. Landa’s B1 S10 commercial press will print on plastic too.

Some dry toner printers will work well with metallised films, some won’t, so the best way to check is to ask your supplier for samples and run a test. Broadly speaking, most are okay, with decent results reported for MGI Meteors, current Konica Minoltas, Ricoh Pro C current models and their Heidelberg Versafire equivalents, as well as the latest Xerox Iridesse.

Non-UV wide-format inks are less certain. Aqueous inkjets can’t print on metallised plastics without expensive extra coatings. Solvent and latex inks should work on plastics, and some models can print opaque white.

Celloglas’ Mirri range is well established and available as board with a wide range of metallic effects, mostly intended for litho or UV inkjet. However there’s a digital HP Indigo capable material in silver or ‘rainbow’ diffraction effects in 255 or 325gsm and sizes up to 500 x 700mm. Celloglas will also apply laminate to your choice of paper or other substrate to special order. Mirri’s data sheet says it will work with HP Indigos and UV inkjets, but for anything else you really need to run tests.

Some other film suppliers have metallics that you can laminate yourself onto paper or board. Graphic Image Films, UK distributer for the Spanish Derprosa range, can supply gloss silver and gold, plus diffraction/holograhic effect materials. A new anti-marking version is out, which is resistant to finger marks. These can be printed by HP Indigo or UV inks, plus some toner types; the company says it’ll supply free samples for trials.

A neat trick with Derprosa and rivals’ soft touch velvet-feel metallic film is to print a clear spot gloss, which smooths out the matt surface to give a near-mirror effect. Scodix in particular promoted this effect after a Spanish customer worked it out, but it should work with any high gloss spot UV varnish.

Scodix (available through Friedheim in the UK) has refined the process, which it calls Metallic: here a gloss silver metallised substrate is overlaminated with an ink-receptive clear matt film for HP Indigo, UV inkjet or some dry toner printers, with blockout white if needed in some areas. Scodix Sense clear spot inkjet varnish is then printed on top. The ink colours the metallic effect where needed and the Scodix Sense brings it up to fully reflective glory.

Nigel Tracey, head of packaging at Scodix, says ‘you can make unbelievably complex coloured effects very easily, but the downside is the cost of materials is very high. It’s mostly used for sample packs and short run luxury packaging.’

The UK’s Kernow Print can supply Metalik, a highly reflective metallic board range in silver, gold and copper, with separate grades suitable for toner print or HP Indigo ElectroInk, and sheet sizes up to B2. It’s also introducing a metallised self-adhesive plastic for wide format printercutters that use solvent or latex inks. If applied to glass, the metallic effect is visible from both sides.

MDV in Germany supplies a metallic silver (not mirror) substrate called UltraSilver, on paper, board or film. This works for some dry toner presses, as well as UV inkjets, the company says. UltraSilver is available from UK paper merchant Elliott Baxter, double-sided in 125-360gsm weights, or single-sided in 120 and 235gsm.

Beata Ulman, senior product marketing manager for commercial and industrial print at Ricoh UK, says ‘We can print on MDV UltraSilver, however we find it very matt and our pre-sales specialists prefer to use Kernow Metalik boards to showcase a true metallic effect to our customers.’

HP Indigos can print white ink over

metallised substrates

White-out

If you print onto a metallic substrate directly, then transparent inks or toners will take on a metallic tint, but they’ll look a bit faded. If you want normal colour to show then a white undercoat can be run underneath. If you print white overall and leave ‘holes’ for the metallic substrate to show though, it resembles spot foiling, but with the digital print advantage of variable images. The results can be striking, especially if the white is also halftoned to vary the metal show-through.

All current HP Indigo presses can print an opaque white as a first colour, which works well over metallised substrates. Dry toner digital presses that can print white include Kodak’s five-unit NexPress and Nexfinity presses; Ricoh’s five unit Pro C7100 and current Pro C7200 models; the old Xerox Colour 1000i and the latest Xerox Iridesse; and OKI’s amazingly good value £1995 Pro7411WT (A4) five colour desktop printer (there is also an A3 model that can print white, but only by removing black).

Hi ho silver

Recent years have seen an increasing number of digital presses with metallic inks or toners. While the results are certainly metallic, they are like silver paint, rather than mirror finish. One the other hand, it’s easy to print halftones and graduated tints for more complex colour effects.

Kodak was the first to introduce a metallic toner, gold, for its five unit NexPresses at drupa 2008. It took a good while to deliver, and so far there is still no silver even for the latest Nexfinity models.

Xerox was next with the option for gold or silver for its five-unit Colour 1000i (a Fuji-Xerox model). Both were the brightest dry toner metallics to date, but were replaced by further improved gold and silver on the Iridesse introduced last year. This has six colour stations, so can print two specials at once out of the choice of silver, gold, white and clear. This opens up a lot of options, especially as the colour order can be swapped around so one special can be an undercoat and one or two can be overcoats.

HP introduced a white ink for all Indigo digital press models in 2010, which was very successful over metallised substrates. In 2013, it introduced the long-hinted silver metallic ink, though initially only for its continuous feed label presses; silver for sheet-fed Indigos arrived last year. Given a seven-unit Indigo this opens the possibility of printing CMYK plus white, clear and silver, in any order.

Some wide format solvent inkjets offer metallic inks. These are essentially silver-coloured, but are intended for overprinting to give other metallic colours.

Mimaki and Roland supply metallic inks on some of their wide format solvent printers, with Mimaki releasing an improved SS21 silver for its CJV300 and CJV150 series printer/cutters in the past couple of years. Mutoh doesn’t have a metallic ink so far.

Efforts to develop metallic UV inks previously haven’t seen great success for reasons to do with the thick ink films. However, Mimaki has recently released a UV-LED cured metallic ink called MUH-100-Si for its UJF-715-plus baby flatbed that looks respectably shiny, so it can be done.

Roland offers silver ink for some of its print-and-cut machines

Swatches and software

Often the digital front ends for metallic-capable printers will automatically generate swatch books which run colours of various tints and combinations over the metallic ink/toner. These can be given unique numbers that when used in the digital artwork as special colours will let the RIP call up the corresponding combinations.

If you don’t have that, then the US company Color-Logic has a software solution and licence for printers to create and print Swatch books for CMYK print over any metallic layer – foil, ink or laminate. It can also generate metallic colour palettes and plugins to load into Adobe Creative Cloud applications. Its FX-Viewer is an on-screen 3D ‘virtual proofing system’ that simulates how metallic-printed artwork will catch the light when rotated.

Swatches can also be created for some metallic substrates with white-capable presses – recent examples are Folex Silver Polyester cut sheet film for HP Indigo presses, and the Kernow Print Metalik and MDV UltraSilver papers for the Ricoh Pro C7200 toner presses.

Spot cold foil on top

We’re seeing more and more methods of adapting hot foil die-stamping foil to digital printing without needing the metal dies. Briefly, they are sublimation foiling, where hot foil adhesive sticks to heated dry toner (or Indigo ElectroInk) print; or foiling units added to thermal laminators, where the rollers heat the print in the same way.

Here we’re examining alternative cold foiling methods that rely on a printed sticky ink as the adhesive (rather than a heat-activated adhesive) on the foil rolls. Foils can be mirror-finish metallics in various colours, but a wide choice of other effects, such as diffraction and holograms, patterns such as wood grains, and solid colours are available too.

Scodix and MGI offer foiling on special versions of their high-build clear UV digital spot varnish inkjets, in formats up to B1. The high build means that the final effect appears embossed as well as foiled.

Precise methods vary, but in Scodix’s case it uses an add-on unit built in the UK by Compact Foilers of Taunton. The Scodix clear UV varnish is first pinned with UV to ‘freeze’ it, and then given a second ‘activating’ zap of UV that makes it sticky.

UK based Autobond also can add cold foiling to its SUV spot UV units that it developed to run inline with its heavy duty laminators for 360, 520 and 740mm sheets. It can also offer hot foiling. Managing director John Gilmore says ‘We have a unique selling point of being the only manufacturer in the world to make a machine that can film laminate, spot UV and foil inline.’

The German foil maker Leonhard Kurz makes B3 and B3 sublimation foilers called DM-Luxliners, but it also offers a dedicated 324mm wide (B2) sheetfed inkjet cold foiler called DM-Liner UV Ink. It uses Kurz’s specially developed Digital Metal foil range, which can be overprinted by HP ElectroInks or most dry toners.

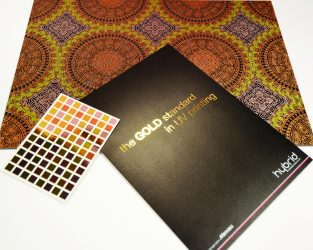

A promotional sample for Mimaki DigiFoil by UK distributor Hybrid

In February Kurz demonstrated its new DM-Jetliner inkjet web digital foiler at HP’s customer event in Tel Aviv, where it ran inline with an HP Indigo 6900 web-fed label press. It can be fitted before or after the press passes through the foil and completes the varnish cure. MGI calls its process iFoil and describes it as a hot foil process, as the ink is heated to make it sticky.

Steinemann, another German specialist, has also developed foiling module called DFoil to fit inline with its DMax spot UV varnisher, available in 72 and 106cm widths. It applies Kurz Digital Metal foils over the spot UV (which can be flat or raised), from up to seven separate rolls, at up to 5000sph. Cold foiling can also be added to the Czech Komfi 36 (B3)and 54 (B2) digital spot varnishers, also distributed by Friedheim.

For smaller formats, UK supplier i-Sub Digital offers a cold foiling option called Digi-Foil for the Mimaki UJF range of small UV-LED flatbeds, based on a modified Vivid Matrix laminator and foil feeder that works with Mimaki’s sticky primer ink. A hand foil feeder can be used with larger format sheets from the JFX200 flatbed, which prints the same primer.

As CMYK digital presses are all ‘good enough’ nowadays, then extra colours and embellishment are a way for a printer to add value as well as offering customers and their designers new ways to catch their customers’ eyes. Bright metal is shiny and eye-catching and people have liked it for thousands of years. Now it’s easily accessible for digital print.

I used to buy a coated high mirrored finish media from Folex (Folajet QD-SI) that would run through my aquaous printers and offer a great metallic/mirrored finish… unfortunately they have stopped producing it.

If anyone know where I can source some, or an alternative coated foil for aquaous printers,… pease let me know. The market demand is there, why would you stop making it!?