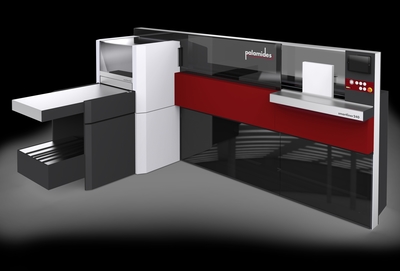

The palamides smartliner240

Short run, high quality layflat and large format books: there is a growing market for such products because they stand out both aesthetically and functionally, when compared to a PUR bound book.

Steve Giddins of Perfect Bindery Solutions has seen it happening through his machine sales, and Ipex 2014 visitors can see it too on the company’s show stand, where three different methods of producing such books will be on demonstration.

Specifically, these systems are the palamides smartliner240, which uses a special adhesive to create layflat books; Smyth’s Digital 88 Book Finishing Line – a thread sewing system that can process flat sheets into sections and then sewn books; and casemaking and casing in systems from On Demand Machinery (ODM).

‘We will be showing a range of different ways of making short run books, and in particular large format books,’ explained Mr Giddins.

‘The ODM systems we will have on the stand are the XXL versions, so can produce books up to 450 mm squared. The palamides can make an A3 landscape book, and with the Smyth you can make a book with a spine length of 520 mm and spine to fore edge of 550mm, so they are even bigger.

‘The feedback I’m getting is that the trend in design agencies is to go for large format books. This is a mixture of photobooks and books for selling expensive properties, where vendors are going to relatively great expense to promote such things.’

Smyth Digital 88 Book finishing liner

Smyth Digital 88 Book finishing liner

He added that most book finishing machines are unable to go beyond A4 landscape size. The systems that will be shown on the Perfect Bindery Solutions stand can go beyond such a format and they can also handle small book sizes too. Mr Giddins provided a run down on the three systems that will form the centrepiece of the Ipex stand: palamides smartliner240- uses EcoGlue, a unique new adhesive that delivers great fibre strength.

Mr Giddins explained: ‘The key to the machine is the adhesive. It has taken Ribler GmbH, the developer, 10 years to meet the challenge of having a strong adhesive which is also flexible. They have developed a spine preparation tool that pulls the fibres out and the development contains a special fibre treatment which combines with the adhesive. An infrared heater then dries the glue instantly, thereby controlling glue penetration. This is followed by another application of the same adhesive and then the cover is put on and the book is carefully moved onto a delivery belt. The book will be manageable much faster than a PUR book.

‘The market is not just photobooks but things like black and white text books, technical journals, music books, and cookery books, because the layflat characteristics are very good.’

Smyth Digital 88 Book Finishing Line- can fold flat sheets into signatures, or accept pre-folded signatures through the feeder or placed directly on the saddle by an operator. ‘Smyth developed the machine having done a lot of research into what printers wanted,’ said Mr Giddins. ‘You get a very high quality sewn book, and the machine is very reliable; we’ve not had a single service call yet for a machine that has been in for two years. Smyth has been building sewing machines since the 1920s. They have been in hard cover book production for a long time and they know what they’re doing.

The changeover time is very quick for short runs. It’s a very good machine for efficient large and small format book production.’ ODM casemaking and casing in- the casemaker is a modular system comprising the gluing unit (Spreader), board positioning unit (Slider), edge turning unit (Stomper) and rotary press (Squeezer). Casing in is performed by the Sticker and Smasher.

‘ODM is the leading supplier in the US and this kit fits into the typical American machine culture,’ he said. ‘They are very easy to use, well-built and reliable, and give you a good quality end product. We’ve sold 14 ODM units in the UK with another three going next week. ODM’s strategy differs slightly from other machines in that the casing in machine has got a small glue reservoir which can be used for intermittent demand with no need to wash up and refill. You can do an order for 10 books or even one book, then leave the glue there and hours later you can run another job. It’s very good for one-offs and short runs.

ODM Sticker XXL casing in and Smasher XXL pressing and forming

ODM Sticker XXL casing in and Smasher XXL pressing and forming