Simon Eccles takes a look at the business potential of small flatbed printers that can apply their images directly onto solid 3D objects.

Think print and most people immediately envisage putting images onto thin sheets of flat paper. It is what Gutenberg did in the 1460s and it is what the first digital presses were built to do too. But there is also a lot of scope for putting images onto thicker objects, sometimes in complex shapes.

Screen printing, pad printing and analogue transfer printing has been able to do this for ever. What we are examining here is the scope for digital printing, directly onto solid items with no intermediate stages.

It is certainly possible to apply digital inkjet print directly onto solid items of quite surprising thickness, as long as they only exhibit modest curves and textures. Large format flatbeds can do this, which is fine if you are printing big exhibition panels day in and day out.

However, there is another potentially big market, for printing onto smallish solid objects such as promotional print, giftware and small POS and signage. Think of phone cases, leather iPad covers, pens, golf balls, plaques, trophies, office nameplates and so on.

This market is open to today’s commercial digital printers as a natural extension to what they are doing already, especially if they are already offering short runs of personalised items such as the ubiquitous business cards. It ties in well with web to print ordering, either B2B, B2C or B2B2C.

Small UV flatbed printers in the A3 and A2 format range have been appearing for the past four or five years. Although there had been largely unsuccessful attempts at solvent based small flatbeds in the early 2000s, Mimaki scored a hit with UV inks and LED lamps on its A3 format UJV-3042FX, introduced in 2009 and selling well ever since. This takes items up to 50 mm thick and now costs £16,995 (a drop of about £5,000 since 2009). In 2011 it was joined by the £29,995 UJF-3042HG, which can accept 150 mm objects. An A2 format UJF-6042 was introduced in 2012, for £39,995.

All models print a maximum of 1800 dpi and offer CMYK plus light cyan and light magenta and will optionally print a primer coating if needed. The original UJF-3042 prints either white or clear ink, while the other two can run both in the same unit. There is a choice of high durability, stretchable or wide gamut inks, and the white has recirculation.

The UJF-6042 can print a complete bed in between 2 minutes 30 seconds and 7 minutes 37 seconds depending on the quality settings.

As with all this class of small flatbeds, the Mimakis need some sort of jig to hold items in place during printing, so the image is applied to the right areas. This can be made from wood, foam, metal or plastic. It is tied into the design system or RIP through simple templates that position the artwork objects to align with the physical jigs.

An optional ‘Kebab 2’ attachment for the 6042 bed can rotate wine bottles and similar cylinders under the print carriage. This is coming to Europe soon.

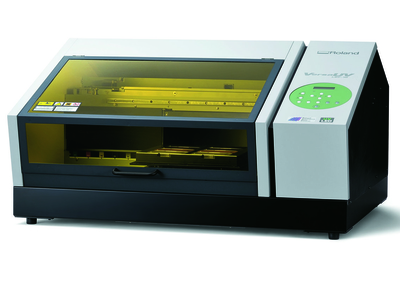

Roland DG introduced its first small UV flatbed, the VersaUV LEF-12 in 2011. It was and remains a remarkably compact design, with a closing lid that keeps dust out and ink mist in (aided by an optional carbon filter system). Its A4 bed format was noticeably smaller than the A3 Mimaki but it originally cost about the same. Last year it dropped the UK price to a more attractive £12,995 and introduced an SRA3 format model of its own, LEF-20, for £19,999.

Roland DG’s VeraUV flatbed systems are remarkably compact

Roland DG’s VeraUV flatbed systems are remarkably compact

The LEF-20 takes objects up to 100 mm high. It has LED curing lamps and the inks are CMYK plus white and clear, in 220ml cartridges. The white ink has recirculation (with LEF-12 you have to manually shake the cartridge). With both printers there’s a choice of matt or gloss finish when curing the clear coating.

The maximum resolution is 1,440 dpi and Roland says the speeds are 7 minutes 20 seconds for a complete SRA3 bed with CMYK only; or 12 minutes 44 seconds with CMYK plus white; and 17 minutes 20 seconds with clear as well.

Speeds probably aren’t a big issue if you’re producing relatively small runs, but if you’re after longish runs of personalised or versioned items for a regular client, they may be a bit too slow. Mat Drake, business manager at at Roland DG, says that there’s been interest in the large format LEJ-640 UV-LED hybrid printer, which can accept items up to 150 mm thick and can be loaded with jigs to hold them. This is 1.6 metres wide with table feeds for 2.1, 2.5 or 3.5 metres length.

Likewise, Duncan Jefferies at Hybrid Solutions, Mimaki’s UK distributor, says that the large format 2.1 x 3.1 metre JFX500 UV flatbed, launched last year, accepts items up to 150 mm deep and can be loaded with jigs to hold items in position.

A few other manufacturers have produced interesting modifications of existing printers. One of these is Croatian developer Azon, whose flatbed UV printer family is sold in the UK by Copytrax, renamed Printmaster Cezanne. There are models with bed sizes from A3 to B0 formats

The originally announced A2 Cezanne uses the upper chassis of an Epson Stylus Pro 4900, normally a roll/sheet fed 17 inch aqueous printer. The A3 model is based on the Epson Stylus Photo R2000, while the B0 model is a more highly modified 24 inch Epson Stylus Pro 7900.

In each case low temperature LED UV curing lamp has been added to the original Epson head carriage. UV inks replace the Epson eight channel aqueous cartridge mechanism with UV inks and feed lines for a choice of 2 x CMYK or CMYK plus 2 x white and 2 x clear inks.

Underneath the original paper feed is replaced by a completely new flatbed mechanism. This moves backwards and forwards under the printhead carriage and the height can be adjusted for items of different thicknesses.

The A2 Cezanne is a desktop model and takes items up to 150 mm thick. An alternative freestanding model with its own stand has an even deeper bed system for objects up to 300 mm. The UK price is £18,750 for the 150mm depth model and £22,000 for 300mm. The A3 model costs £15,000 and the B0 is 39,000.

Objects are positioned and secured in the bed by jigs made of wood, plastic or metal. Copytrax can make up jigs to order, with B2 costing about £300 for metal or £125 for acrylic, or customers can make their own.

While solvent inks didn’t work too well for early small flatbeds, Steve Woods at Copytrax says that the inks have ‘come along enormously’ in the past three or four years. The company sells a solvent based range called Rubens, again with Epson heads. An A3 model costs £9,995 and an A2 model is just under £13,000. A solvent gel ink version of the Cezanne has also been developed for a special order.

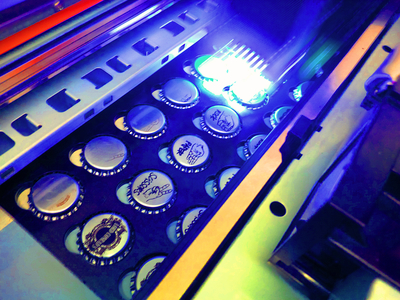

Printing on beer bottle caps with the Copytrax Cezanne

Printing on beer bottle caps with the Copytrax Cezanne

‘Solvent gives a much smoother, high res finish for colour photographs, because the ink has time to flow, unlike UV,’ says Mr Woods. ‘It’s very good for plastics, where the heated bed helps the ink etch into the surface.’

On the other hand UV can be used with a wider range of materials, he says, and the items are ready for handling and packing immediately. Solvent has to be left for a few hours for the ink to fully cure and harden.

Anther company that modifies existing printers is Bergstein in Holland. Originally a supplier of pad printers, Bergstein has now added a range of modified Mimaki UJF flatbed UV printers, painted blue and with new bed mechanisms that accept thicker items than the original printers. Some of these models are distributed in the UK by Kaye-Dee Marking Solutions.

Bergstein’s BE 300 model family is based on the UJF-3042 but added ‘industrial’ features such as anti-static ionised air circulation and extra microswitches on the guards. It’s available in three models with 50, 150 or 300 mm item heights. The ionisation helps ink adhere to uneven surfaces. Prices range from £25,000-£33,000 depending on spec.

The new BE 600 is based on the A2 format 1800 dpi UJF 6042, with the same extra features and version with 150mm, 300 mm and 500 mm depth vacuum beds. Prices range from £45,000 to £60,000. There’s provision for a robotic arm loading/unloading system, demonstrated at the recent InPrint event in Hamburg.

Transfer alternatives

Small flatbed printers are impressively versatile and the outlay isn’t huge compared to a large UV flatbed. Other the other hand, direct printing isn’t the only way to get images onto solid items. We’ve covered thermal transfer papers in the past (such as TheMagicTouch Wow!), that can be printed by very low cost desktop toner printers. There is also the option of dye sublimation transfers that can be used with almost anything made from or coated with polyester. Heat-stretch vinyl, as used for vehicle wraps, can also be used to wrap smaller things such as laptop cases or cycle helmets.

Digital UV (or solvent) flatbeds really seem to score for smallish items that would benefit from the one-step full-colour process, with no time consuming transfer or finishing stages), or where subtle effects are needed – Roland’s print product manager Mark Elvidge cites the example of a laptop case with an image that fades off toward the edges. The cool running UV LEDs lamps used in most small flatbeds also allow the use of delicate or heat-sensitive media that a heat press might damage.

Probably, as with so many processes in print, a UV flatbed would be just one of a whole range of tools you’d need to be able to handle all contingencies.