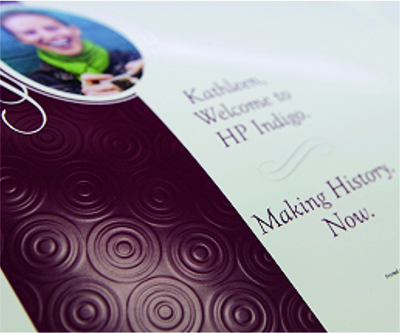

HP’s raised print uss up to 50 ayers of transparent ink

Basic greetings cards can be a relatively simple print job, but there are numerous ways of adding value to the product through print and finishing technology.

With little more than a digital press that can handle, say, 300 gsm card, and some basic finishing equipment for guillotining and folding, theoretically the short run greetings card market is one that almost any print provider could make steps into.

To make waves though, to stand out from the crowd, requires something more. There are paper stocks such as Tullis Russell’s Trucard, coated one side, which are ideal for greetings cards and are available from a number of UK paper merchants. But you might like to seek a little extra quality differentiation through a paper grade such as Fedrigoni’s Tintoretto Gesso (available from Premier Paper), which is a high quality uncoated board with a felt mark finish and off-white shade.

There are many creative papers in the market, including dark, coloured and metallic stocks, and some of today’s print engines also are able to deliver special effects that can enhance both these creative papers and basic white paper grades. Kodak and HP Indigo in particular have been prominent in this regard – Kodak with its fifth imaging unit solutions, and HP Indigo with white and transparent inks and its ‘one-shot’ option that makes it possible to print on substrates, including PVC and synthetics, as thick as 600 microns.

‘We get most of the ideas from customers who have a specific application in mind,’ said Vivian Cohen Leisorek, market development manager at HP Indigo. ‘For greetings cards, everything goes: different types of inks – white ink opens doors to a lot of ideas – and effects such as raised print, which is fully variable; that’s been a big hit in the last few years. The fact that each one can be different allows them to use it for personalisation. We’ve seen companies in both Germany and the US use raised print for Christmas cards. That’s a really premium application on the 7600 and 5600 presses.’

These HP Indigo presses can also produce embossing and debossing effects, which HP Indigo calls textured and reverse textured. ‘In terms of textured effect, that has been used less but it also takes more preparation. It does enable you to do embossing and debossing in-house, without having to create a mould for embossing,’ said Ms Cohen Leisorek.

The raised print and textured print effects are achieved in very different ways. Raised print is created by building up layers of transparent ink, up to 50 layers, directly on the substrate. The textured print, which gives an embossed/debossed effect, is produced by stopping the flow of paper to the HP Indigo press and printing up to about 250 layers of ink onto a piece of cardboard (or Digital Mold Media) that is attached to the cylinder that usually takes the substrate. This becomes the die, and when the flow of paper is renewed, the blanket acts as a cushion between the mould and paper to create the textured effect. It is not as crisp or deep as true embossing, but it allows print service providers to do short run embossing in a matter of minutes.

Kodak also offers a raised print effect which it calls Dimensional Printing, also based on a clear ink. It has been busy introducing new inks and finishes for its Nexpress fifth imaging unit in recent years, with red fluorescent and light black being augmented by glossing and coating solutions, and most recently with Gold Dry Ink (as was used on the front cover of Digital Printer in February 2013). Xerox also supplies a clear dry ink that can be used for highlighting images and text or digital watermarking.

Chance to enhance

Digital enhancement comes from companies such as Scodix and MGI Technology as well. Scodix uses an advanced jetting block and multiple independently controlled inkjet nozzles that produce UV polymer in small drops and multiple layers, which it can build up to 250 microns thick. There is also the option of Scodix Rainbow, a dedicated digital inkjet glittering station that produces glitter effects on selected areas, in any colour or transparency – ideal for greetings card applications.

Lawrence Dalton at 1st Byte took one of the first Scodix presses in the country, and in Digital Printer March 2014 he spoke in glowing terms of the special effects that the press can produce, which include printing with white and clear ink onto black and heavy substrates. ‘The reaction has been brilliant,’ he said. ‘This is absolutely right for our clients who want high value, high quality, short run print jobs.’

MGI’s special effects come via its JetVarnish 3D digital spot UV coater, and the Ipex-launched iFoil, which allows JetVarnish users to produce both flat and digitally-embossed hot foiling on demand. David Evans of MGI in the UK told Digital Printer: ‘Certainly greetings cards is a big area of interest for us. Companies are getting really interested in variable foiling in short runs. iFoil means you can do personalised foiling for the first time. You could add 50p or whatever for customers to add their loved one’s name in foil, and that could be a very nice upsell that costs pennies to produce. You can also use it for proofing, instead of setting up a die for £500.’

Textured effects on a greeting card

Textured effects on a greeting card

Ideal for web

Even more important than having a great product and the means to produce it is the ability to sell it effectively, and this is where software comes in, with numerous specialist web to print, photo gift and personalisation products on the market.

Two of them – DirectSmile and Taopix – are sold by Transeo Media. It is important to get software choices right from the beginning, said managing director Neil Bather, and to understand the role that each product plays.

‘We are seeing printers moving into the greetings card space because there are niche markets for all types of print. It’s not confined to just the big players, there are different levels and niches,’ he said. ‘DirectSmile has been very successful in that market. The big players are using it and whenever we get into a sales cycle with these customers, there are lots of web to print systems out there for them to look at. DirectSmile stands apart in scalability. It’s a composition engine. It interacts with a website, so that the printer can develop the look and feel and customer interaction they want, and when a customer chooses a product, types in their name and hits preview, DirectSmile generates that. This flexibility is an important factor in this market.

‘With scalability, no-one deploying this type of application should do it just for the average workload, you’ve got to do it for the peaks. DirectSmile is truly load balanced to handle the volume. You can’t have a customer waiting a long time for a preview – they will go elsewhere. We can render many things at the same time and can have as many instances at the same time.’

Taopix meanwhile can create personalised cards also, but as more of an add-on to a range of gifts, since its flexibility enables many more photo gift products such as mouse mats, mugs etc. to be offered. A user buying Taopix gets everything in the box, a total end to end solution, whereas DirectSmile is an engine for rendering products, and requires an end user to build an ordering system around that.

Mr Bather added: ‘The biggest business challenge we need to advise customers on is getting workflow in place to handle runs of one. A lot have processes for short runs but their workflow practices might have to change to accommodate lots of single orders coming through.’

The greetings card advice from HP Indigo is three-fold. ‘Don’t be afraid of design,’ said Ms Cohen Leisorek. ‘There are a lot of myths around. Designers are often guided by how a job is going to print and if it is digital they stick to the simple ABC and don’t use other opportunities. So work with design; think of all the options with inks, papers and effects. Secondly, think about the best use of substrates. We can now do eight-up applications that used to be two-up. And thirdly, the use of photos: it faded away but it is back again, and consumers are much more open to it. It’s something that PSPs can easily integrate into their existing workflows as an offering, especially with all the photos we now carry on phones and digital devices. It’s a great way to integrate with print.’