A new best practice guide shows how to ‘do PDF/VT right’ to maximize productivity and minimise turnaround in the time and profit-critical world of variable data print

The Hollywood entertainer Eddie Cantor once remarked “It takes 20 years to become an overnight success.” For much of the last 15 years or so, evangelists for variable data in digital printing (VDP) knew the feeling: widely regarded as “the next big thing”, the technology took a while to reach the tipping point and realize its vast, untapped potential.

When it did, things changed quickly. Today, VDP is routinely used for all manner of personalized information – from credit card bills and bank statements to direct mailshots and personalized catalogues, from college enrolment packs to photobooks, from cheques to tickets.

These jobs are created and managed by a wide variety of software, from specialist composition tools to general-purpose design applications configured for VDP, and they pass through workflows involving – or even completely within – the digital front end (DFE) for a digital production press. A similarly broad variety of people use these tools, from graphic designers and marketing campaign managers, through experts in data management, to – last but definitely not least – digital press and finishing equipment operators.

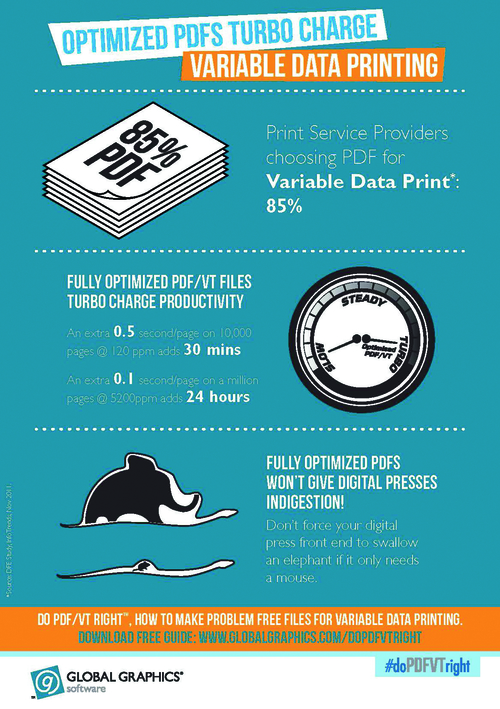

The result is the evolution of a huge number of complex, sophisticated workflows. Many of these are based on PDF and its standardized subset PDF/X, which have become the dominant delivery formats for conventional print and print-on-demand (PoD). According to InfoTrends, 85% of print service providers are using PDF for their VDP work.

Recently PDF’s pre-eminence has been reinforced by the PDF/VT format, designed specifically to support robust delivery and production of modern variable data print jobs. PDF/VT enables graphic designers to apply many of the features they use in commercial print and publication work to complementary direct mail and transpromo campaigns. The format also includes metadata such as JDF that can be linked to a job ticket, allowing for more automated processing and finishing.

PDF workflows work very well most of the time. However, as VDP jobs themselves become richer and more complex, they place additional demands on the processing power of the DFE: printinga VDP job at 120 pages a minute means RIPping120 pages a minute. Each minor inefficiency in a VDP job often only adds between a few milliseconds and a second or two to the processing of each page, but multiply those times by the number of pages in the job and the problem becomes clear. A delay of half a second on every page of a 10,000-page job running at 120 pages per minute adds 30 minutes to the whole job; for a really big job of a million pages an extra tenth of a second per page at 5200 pages per minute adds 24 hours to the total processing time.

As a result, constructing PDF files properly – ‘optimizing’ them – has become critical to production efficiency. Poorly constructed PDF files can impact print service providers in two ways. Firstly, the additional processing they require slows down the digital press, reducing the return on investment and disrupting production schedules that are typically tight, particularly for variable data direct mail and transactional print. Secondly, they can make the DFE more expensive because to expand the processing capability the press vendor builds in more hardware than would be necessary if all jobs were well-constructed.

Martin Bailey: ‘Don’t force your digital press front end to swallow an elephant if it only needs a mouse!’

Monte Rose, research & development manager for media solutions at Quad Graphics, vividly describes the challenges VDP printers face far too often: ‘We have all seen files that will ‘rip’, but not necessarily in a timely fashion. With VDP files we see it more frequently – files with too many fonts, too many layers, or too many images. The RIP has to sort the bits out within an ever-shrinking window of time to meet print engine speed. Any slower, and the job isn’t going to finish on schedule. Your options are to schedule extra RIP time, which isn’t usually practical, or split the files across multiple redundant RIPs, which is costly. Or you can redesign the file to simplify ripping, which is risky – you break it, you own it. And whatever you do, you have to hope it doesn’t affect the final results.’

Steps to optimize PDF/VT

Fortunately there are a number of simple measures designers and users of VDP can take to streamline the PDF workflow, as a new independent guide to optimizing PDF files explains. Do PDF/VT Right: How to Make Problem-Free PDF Files for Variable Data Printingis a concise (68 pages plus covers, A5), readable, independent guide that provides objective information and advice to anyone with a stake in VDP print: graphic designers, print buyers, production managers, press operators, print company owners, and digital press DFE developers.

The guide, which is available free of charge, is edited by Martin Bailey, chief technology officer for Global Graphics and the primary UK expert on the ISO committees that maintain and develop PDF and PDF/VT.Do PDF/VT Rightis sponsored by a number of other leading vendors in the VDP sector – DirectSmile, Global Inkjet Systems, HP Indigo, HP Inkjet High-Speed Production Solutions and Screen. The content is rigorously vendor-independent which is why the guide is also endorsed by the PODi and Xplor industry associations.

The elephant and the mouse

Martin Bailey says the main aim of the guide is to promote one simple maxim: ‘Don’t force your digital press front end to swallow an elephant if it only needs a mouse! In other words, don’t ask the workflow to do more than it needs to if there’s no benefit for the designer, marketing department or recipient of the printed piece. There’s no intention of reducing the freedom of the designer to achieve the visual effects they want to – just to ensure their design can be encoded into a PDF file as efficiently as possible.’

The content of the guide is organized so that readers can easily find concise, practical and, importantly, actionable information relevant to their role in VDP projects. The first two sections, for example – ‘Why PDF for VDP?’ and ‘Why does optimisation of VDP jobs matter?’ – provide an overview of the key issues for less technical readers. The content then turns more technical for those with a more ‘hands-on’ involvement, covering topics including optimising images (for example, by matching the effective image resolution to the output resolution of the digital press), and optimising transparency.

Mr Bailey says that transparency is a key area where improvements can be made. ‘The very rich and flexible support for live transparency in PDF is an incredibly useful aspect of the format, and is one of the key reasons for selecting PDF over other page description languages for production print. On the other hand, compositing transparent regions in a PDF file is much more processor-intensive than handling opaque areas of a page. For example, we see PDF files where images have drop shadows attached to them – even though they’re on a solid black background and the shadow can’t be seen. Simply gaining a better understanding of what’s happening inside the PDF can have major benefits.

‘Another common example is a high resolution image placed at a very small size, so it has an effective resolution several times higher than the press it will be printed on; that needs a lot more processing, but doesn’t increase the quality of the printed image at all.’

To download a free copy of ‘Do PDF/VT Right: How to make problem-free PDF files for variable data printing’go to: www.globalgraphics.com/doPDFVTright.