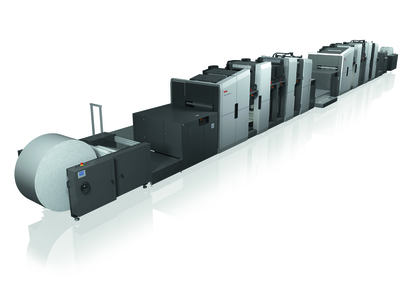

High speed digital inkjet presses for commercial and publishing applications.

The Kodak Prosper 6000 Series was announced to the world in June 2014, complete with new innovations in transport, drying, and writing systems, and advanced press management technology that the company said made the presses a ‘completely new product offering that deliver high levels of reliability, print speed and application flexibility’.

Two models cater for customers in the commercial print market on the one hand, and book and newspaper sectors on the other:

The Kodak Prosper 6000C therefore is ideal for commercial print applications requiring high-ink laydowns; while the Kodak Prosper 6000P is designed specifically for publishing applications which typically use light weight paper and low to medium-ink laydowns.

Both presses are powered by an advanced Intelligent Print System (IPS) that continuously monitors, evaluates and adjusts operations to ensure exceptional quality output. With the improved IPS, the Prosper 6000 presses can monitor and instantly correct colour registration, delivering enhanced registration performance. The 6000 press’s writing system runs on Kodak’s newly formulated nanotechnology inks, offering a greater colour gamut and delivering print quality that the company says rivals offset output on a wide range of uncoated, coated, and glossy papers.

The presses print at speeds of up to 1000 feet, or 300 metres, per minute on matt and uncoated papers, with a duty cycle of 90 million A4 top quality pages per month. This is up to 2.5 times faster than the Prosper 5000XLi press. An enhanced drying capability allows heavy-weight glossy and silk stock to be printed at 650 feet (200 metres) per minute. In addition, saleable prints can be produced at a low cost per page – less than £0.004 per A4 page in colour consumable costs. Kodak said the Prosper 6000 presses also provide customers with long inkjet head life, high operational uptime, and fast job set-up and make-ready time, helping them save both time and money.

The first customer to install the 6000C commercial version was US printer Japs-Olson, a commercial and direct mail print service provider based in Minnesota, and a long-time Kodak user, having started using Versamark imprinting systems more than 18 years ago, before enhancing its offering with the Prosper S-Series imprinting systems. It helped to beta test the press, pushing it to its performance limits.

‘The only way to ensure long-term success in the printing industry is to provide the greatest quality to customers while being laser focused on productivity and efficiency,’ said Michael Murphy, president of Japs-Olson. ‘As we have become familiar with the Prosper 6000C press, we are certain that the future of printing will be tied to this leading innovative product family. The early indications of its production capability and stunning quality are a testament to what the next generation of digital printing can do today.’

Whether your business is in commercial printing or publishing applications such as books and newspapers, Kodak maintains that the Prosper 6000 presses deliver a persuasive economic argument. Printers in the commercial print space, for example, are looking to provide their customers with better response rates for mailings. The Prosper 6000 can produce high-gloss targeted direct mail pieces for an average of 30% less than toner-based systems, according to Kodak, delivering a greater return on marketing spend, as well as improving efficiency and profitability for production runs of up to one million high-quality mail pieces.

In book printing, where printers are looking for ways to enhance revenue potential by shifting to profitable short-run jobs, they can reduce inventory costs and print shorter runs on a just-in-time basis to meet specific orders. The Prosper 6000 makes it feasible and economical to print up to 200 lpi quality books at production run lengths of up to 3000 copies. In addition, it can produce millions of offset-like pages month after month, and reduce the costs associated with obsolescence and warehousing.

Streamlined newspaper print runs and versioned editions to target different readers are benefits for the newspaper market. Digitally printed newspapers can have a high quality appearance that is readily accepted by advertisers and readers. The Prosper 6000 allows multiple newspaper titles to be produced in very short runs, with sufficiently high productivity for medium-sized markets (15,000 to 20,000 newspapers) too.