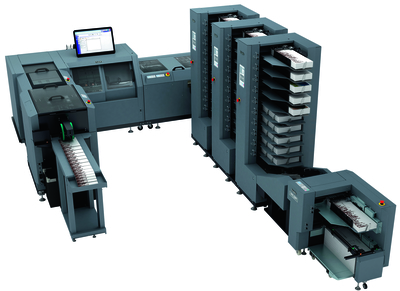

A fully automated, intelligent and flexible saddle stitcher.

The uniqueness of the Duplo iSaddle lies in the fact that the system can suit both the traditional offset commercial printer as well as the typical digital printer. In short time (from 30 to 60 seconds, depending on the job’s format), the operator can switch from an offset printed job to a digitally printed job, requiring multiple sheet feeding or custom feed sequence, thanks to the PC-controlled intelligence incorporated into the system.

This was a key aspect that persuaded Leicester company Flexpress to invest in an iSaddle, alongside the saddle stitcher’s ability to produce A4 landscape books – a growth market for the company.

Booklets already comprise almost half of the Flexpress turnover, and this is expected to rise by another 20% in 2015, so that it will account for £2 million of its business. It wanted to upgrade from an ageing finishing system, and was on the lookout for a modern, automated system, with individual fan-controlled collator bins, which would enable it to independently adjust for litho and digitally-printed jobs. It also wanted a finishing system that was easy enough for the majority of its workforce of 26 to use, and one that was more environmentally and economically friendly to run.

It found the answer in Duplo’s iSaddle, investing in a system with an intelligent collator tower configuration that can have up to four collating towers. It includes four staple heads and a cutter trimmer for two-up production. Other benefits included a PC controller, and full automation that has led to dramatically improved make-ready times and quick size changes.

Steve Wenlock, managing director of Flexpress, said: ‘We are conscious that in an increasingly digital world, people work in hours, not days, which is where Duplo has really helped us. The results from the iSaddle system have been phenomenal. Not only has the A4 landscape option increased our ability to win contracts by around 30%, but the productivity has been superb thanks to the ease of use and fast make-ready speed, which is as little as five minutes, a two-thirds reduction on the previous system.

‘Overall, I’d estimate that there’s a 60% time saving for jobs on the iSaddle System. We’re down from four cuts to just one, plus the central cut enables us to double the speed, with A4 spec jobs now running at 2750 an hour. I have been really impressed by the outstanding quality; the books are twice as flat as those from our old system.’

The Duplo iSaddle comes in three different configurations: the iSaddle System, which consists of up to four collating Towers (DSC10/60i) of 10 stations each; the iSaddle Digital System, which can be connected to a Sheet Feeder (DSF2200); and the iSaddle Duetto System, which will accept both the collating towers and a Sheet Feeder.

It can produce booklets from CD inserts to A4 landscape, and can run booklet thicknesses up to 120 pages. The folding wheels are automatically positioned to produce flatter books. Although the maximum output is 4500 books per hour, the addition of the optional DKT-200 trimmer and gutter cut knives, increases this to 9000 per hour. Stored jobs can be recalled almost instantly, with set up time taking 60 seconds or less.

Each suction tower of 10 bins comes with AMS+ (Air Management System Plus), which manages the high power fans that create air flow and vacuum independently for each bin, enabling reliable feeding. They also include IMBF (Intelligent Multi Bin Feeding), which allows the operator to select each bin independently if required, and to feed single or multiple sheets from each bin – a huge benefit when producing variable data publications.

Printers have a choice of two, three or four heavy duty Hohner wire stitching heads in both flat and loop stitch configurations, and precise control of the book is maintained along the spine, using motor driven stops and twin drive belts.

Robin Greenhalgh, chairman of Duplo International said: ‘Complementing Duplo’s existing line of quality fully automatic bookletmakers, the iSaddle System offers printers a wealth of features that will allow them to grow and improve the profitability of their business.’