EFI’s Productivity Suite is much more than a new umbrella term for the company’s increasingly diverse range of software; it aims to guarantee workflow integration and to optimise overall print company productivity from marketing through to post-production.

EFI has been on a software buying spree for over a decade now. Since the 2003 acquisition of Printcafé, the digital imaging company has bought more than 25 other software developers and programs, 16 of them in the last five years. These include Radius Solutions with its packaging-focused software, regional MIS/ERP players like Prism Group Holdings in Australia, Metrics Systemas de Informaçao in Brazil, Belgium-based GamSys and DiMS! in the Netherlands, together with developers of complementary technologies such as Metrix (imposition), Polymeric Imaging (thermoforming inks) and DirectSmile (cross-media).

In 2014, EFI’s software division was responsible for 20 per cent of the company’s US$790 million turnover, so it would be a substantial concern on its own, even without the Fiery digital front end, wide-format inkjet, ceramic printing and consumables businesses that it supports and complements.

Alongside a series of record quarterly results and the burgeoning product line and user base, EFI’s annual customer conference Connect has been growing by leaps and bounds. This year’s event, held in Las Vegas in January, saw a double-digit increase in attendance over the previous year and sold out, hosting some 1500 delegates.

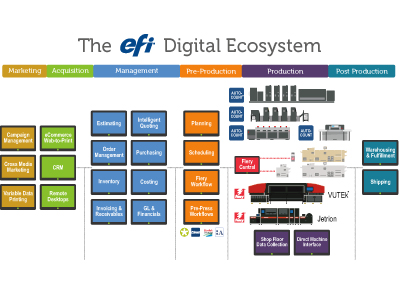

One of the most significant announcements at Connect was the EFI Productivity Suite. Presented as the next step in the evolution of EFI’s product portfolio, Productivity Suite is a reorganisation and integration of the existing offerings that builds on their strengths to provide business automation, optimisation and new revenue generation capabilities that address the printer’s business as a whole, from the customer’s desktop to the printer’s administration, production floor and delivery services.

Holistic approach

Productivity Suite shifts the emphasis away from specific admin tasks, production operations or software packages to a holistic view that underpins a comprehensive portfolio of print business performance-enhancing tools and capabilities.

To support this model, EFI has organised its software range into four areas based around business functions common to all print enterprises: new revenue generation; efficiency and profitability; pre-production; and production; all of which link into EFI’s core MIS/ERP platforms.

The new revenue generation group includes cross-media marketing with DirectSmile, e-commerce via the popular Digital StoreFront web to print software, customer relationship management (CRM) and warehousing and fulfilment tools. Efficiency and profitability relate to MIS-type functions such as estimating as well as production management tasks like scheduling and resource optimisation, planning and layout optimisation, plus higher level business intelligence tools.

Pre-production and production cover the obvious Fiery-centred processes – pre-flighting, imposition, integration with prepress workflows from other vendors like Kodak, Agfa, Heidelberg and Esko, colour management, DFE and job management – but also version planning, shop floor data collection via manual methods or direct machine interface (DMI) and shipping operations.

The central MIS/ERP provides the familiar functions: estimating, order management, internal or external business portal, reporting and analysis, purchasing, receivables and inventory tracking, costing and other financial data.

Going global

To make all these elements work together automatically such that the business as a whole is optimised requires some ingenious software. While you would expect that some kind of consistent branding would need to be applied to all those acquired companies and products, if only to make life easier for EFI’s sales and marketing people, the conceptual basis for Production Suite is much more substantial and significant than that.

The EFI Productivity Suite is founded on a principle called the theory of global optimisation (TGO), developed over many years by Udi Arieli, previously with Printcafé and now EFI’s senior director of Product Management.

The problems facing the print industry are familiar – decreased profitability because of changing demand, changing production processes, shorter runs, lower prices yet higher costs, shorter lead times, increased numbers of make-readies with too much waste, and an increased variety and complexity of products to be produced. An obvious solution is to increase throughput using existing resources, but it is not as simple as just trying to do each bit faster. Indeed, measuring performance in individual cost centres often works against optimisation of the business as a whole.

Mr Arieli saw that modern print shops have multiple interdependent processes, some of which can only be done serially in a set sequence and some of which may be carried out in parallel, making manual decision-making for maximum overall efficiency nearly impossible. Successful manufacturing philosophies such as the ‘lean’ principle pioneered at Toyota or the Theory of Constraints model developed by Eliyahu Goldratt contributed some useful ideas, but it became apparent that neither could fully address the unique workflows and complexities of print.

Lean manufacturing focuses on reducing work in process at every stage, but counter-intuitively, running larger queues in print businesses can improve the utilisation of their capacity by allowing jobs that require the same substrate, ink set, printing or finishing device to be batched and run together, minimising set-ups and wastage. Constraints-based thinking cannot distinguish between a bottleneck like this which may actually improve overall throughput, and a genuine ‘weakest link in the chain’ constraint, such as poor finishing which could potentially eliminate all the value added in the printing stage. TGO, by comparison, recognises that profitability is created by the sum of all jobs, not the theoretical profitability of individual jobs.

Mr Arieli’s work was developed initially into the PrintFlow Dynamic Scheduling capability found in EFI’s MIS and ERP offerings. This can take into account the entire workload, including outsourced operations, and apply both production logic and business rules to optimise workflow. Examples of production rules are quite obvious – a colour job is not run on a mono press; if a job requires inkjet overprinting and there are four inkjet heads that can be used on six binding lines, the job is scheduled to be sent to the binding lines only when the inkjet heads will be available, for example. Business rules are less immediately apparent but address factors such as parallel cost centre load balancing and employee skill sets.

This capability has become indispensable for customers running complex production schedules with thousands of jobs each day. The same logic has subsequently been applied and extended to cover the whole business’s ‘ecosystem’ in the Productivity Suite.

Certified to work

This TGO-based end-to-end automation is complemented by certified workflows. These are groups of EFI (and sometimes third-party) products that have been extensively tested to work together which can therefore offer ‘out of the box’ integration. This allows data to flow seamlessly throughout the business, eliminating the need to re-key, recreate or re-interpret information generated by the salesperson or customer at the outset of a job. Eliminating non-chargeable communication-related work yields an immediate cost benefit but also improves office efficiency and shopfloor performance.

The certified workflows are supported by synchronised product update cycles, so that all the key components remain in step, ensuring that the integration does not break over time. Automated upgrade mechanisms for most products should ensure that new revisions are implemented seamlessly and so avoid disruptive sequential upgrade processes.

For litho-based commercial and publications printers, mailing and fulfilment houses, there is an Enterprise Print Suite based around EFI Monarch MIS/ERP. Packaging customers producing labels, flexible packaging and folding cartons using a mix of litho, flexo and digital print technologies are served by the Enterprise Packaging Suite centred on EFI Radius ERP.

Commercial printers with digital capability are likely to find the EFI Pace-based Midmarket Suite the best fit, especially if they also have wide format printers or carry out fulfilment operations.

The Productivity Suite is designed to let the printer or packaging business select the components required to address their current ‘pain points’ with the flexibility to grow the system as their needs, market and product mix change. This makes it a long-term solution that avoids the need to start over as the business evolves.

Upgradeability is built in to the Productivity Suite at all its levels so that all users can benefit from the evolution of the product portfolio as it expands in both breadth and depth over the coming years. EFI will be expanding its cloud-based offerings and software as a service (SaaS) options and will develop additional end-to-end workflows for specific markets and printed products, aiming to incorporate business process ‘best practices’ as it does. The Suite will also be augmented with an expanded range of services from EFI, including business process consulting, enabling Suite users to maximise the benefit of their software.

The productivity proposition

Whichever Suite is appropriate for a print business, it is intended to deliver the same benefits. All versions of Productivity Suite provide tools to help generate new revenue through better customer management and an expanded service offering to existing and prospective customers. The certified workflows are designed to give the highest level of end-to-end automation without compromising flexibility, in order to maximise predictability and profit through optimal use of resources.

Detailed business-wide analysis of operations with real-time display enables informed, proactive decision-making, allowing schedulers to manage the workflow in advance, increasing transparency, accountability and communication throughout the business. Because it is designed specifically for printers, the EFI Productivity Suite will scale to support both planned growth and opportunity-driven diversification.

EFI has shown very strong and sustained financial performance and the company has many market-leading products across a growing number of complementary sectors within print of all kinds. Its history of innovation and statements of intent to continue investing in further development provide compelling reasons why printers who want to make the most of their existing resources and develop their businesses should consider it as a partner.