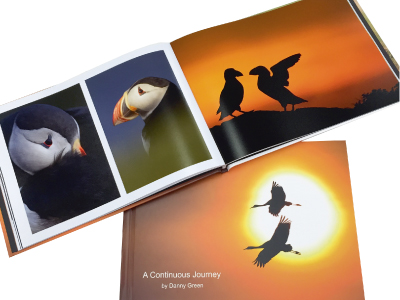

2M Professional produced 1000 copies of a photobook on its Canon DreamLabo

A market exists and the technology is available to produce short run coffee table books but at the moment the price is not right, finds Simon Eccles.

Since the turn of the century, digital cameras together with high quality digital printing technology and associated fast makeready binding, have facilitated the emergence of a whole new market for one-off photobooks. Now we’re starting to see high volume digital inkjet web presses expand from the long-standing monochrome books market into medium-quality, longish run colour books. But is there a gap in the middle, for high quality colour books in quantities of high tens to low hundreds?

These might classed as ‘coffee table books’, covering art, photography, travel, and enthusiast/hobbyist subjects.

However, today the costs are high. All the online photobook and self-publishing ordering sites such as Blurb and Lulu.com switch to silly price mode for full-colour books with a decent number of pages – say 60 to 80. They’ll offer modest discounts for quantities of 50 or 100, but even so it is hard to get the unit price below £30 or £40 each, and that’s before you add margins for the author and retailer.

Harrier’s new target

That is not for the want of trying. Harrier in Newton Abbott is a very large photobook and photoproducts facility, handling its own Truprint and Snapfish brands plus work for others such as Tesco. It introduced a medium run books facility about three years ago, concurrent with its installation of a Kolbus casemaking and casing-in line. This can switch sizes very quickly. Six SRA3 format HP indigo presses handle printing. ‘We always ran orders of one, but we then print in batches of 50 of similar size,’ says business development manager Julian Marsh. ‘When we put the Kolbus in we started thinking about larger markets, initially through our trade services. Looking at our recent orders, we have had quantities of tens and hundreds.’

The problem with digital is that unit cost does not fall much with higher numbers, he says. ‘They are not cheap books,’ Marsh admits. ‘We charge the publisher £30 to £40 for small runs, and they put their own prices on top. Once you get to about 20 copies our economy of scale is fairly small. We tend to heavily discount the make-readies, especially if they’re prepared to wait a week or two. We’ll wait to get a number of orders together and run them concurrently.’

Higher volumes may allow some leeway on the pricing in future, he feels. ‘If we do not do it, somebody else will. If there’s going to be disruption we would rather be part of it.’

East Anglian experience

2M Print in Norwich, a smaller print operation that has specialised in B2C, B2B and trade photobooks since it was set up in 2007 tells a similar story. It has an HP Indigo 5500 and a new Ricoh Pro 9100C digital press (the latter with long sheet capability up to 790 mm). It also has the UK’s only Canon Dreamlabo 5000, a high quality but slow roll fed inkjet press designed to print photoproducts, including books in formats up to 300 x 300 mm. The business is split into two, a B2C offering Smileyhippo for ordering of template-based photobooks via its Taopix-driven website, and 2M Professional a B2B service that offers bespoke book manufacturing, often in runs of 25 to 50 copies.

Two years ago 2M invested more than £300 000 in automated finishing kit. ‘We now have the capability for about 2500 books per day,’ says director Mark Hipperson, ‘though we have never got to that yet.’

Corporate event books for Chrysler are another short run colour application for 2M Professional

The biggest order to to date has been for 1000 books for wildlife photographer Danny Green, produced on the DreamLabo. Larger orders don’t lead to significantly lower costs though. ‘Digital is only way to do it with 25 or 50 copies, Mr Hipperson points out ‘But that pushes up the unit cost, and if you are selling-on, that is a problem. With an 80 page book you are looking at more than £35 to £40 per book.’

Press choice

Digital presses that are good enough for one-off colour books are equally suited to 50 or 150-off, though speed may become an issue. Sheet-fed HP Indigo and Kodak NexPress machines have been widely used for photo books. You could use many of the colour presses on the market, with a suitable silk or matt paper. Canon, Konica Minolta, MGI, Ricoh/Heidelberg, and Xerox toner presses are all suited to decent quality book work.

The growing popularity of mid-range ‘long-SRA3’ models with sheet lengths ranging from 660 mm to 1200 mm has significance in the colour book market, as these allow larger format landscape covers and lay-flat sections beyond A4 to be printed. B2 presses also have a ‘long sheet’ advantage as well as double width.

Final assembly

Binding is the key part of book production. Ashgate International sells the Finnish-made Fastbind range of modestly priced and easy to use manual glue binding, casemaking and layflat equipment into the short run and high quality photobook market. The Unibind range is another popular entry level binding system, which offers a range of pre-made covers called Planos, incorporating a steel spine strip and heat-activated adhesive to hold the blocks. You can also make your own cases if the size is unusual.

Perfect Bindery Solutions sells equipment from On Demand Machinery (ODM) that represents a step up, with a range of larger capacity assisted manual, motorised or full auto case making, gluing and layflat binding systems. Whether you’re making soft or hardbound books, PUR binding is a good idea for the coated papers and toners used in digital print. PUR is no longer a pernickety high-end option, with single clamp binders now available from the likes of Duplo, Horizon and Morgana at £20000 to £30000.

You can pay less than that: Duplo sells an attractive little bench top PUR binder, DB-280, for under £8000. It can handle manually fed books up to 320 x 400 mm and up to 40 mm thick, at a claimed maximum of 200 per hour. If you have already got a hotmelt binding system it may be possible to convert it to PUR. Futuregrafic converts existing lines to PUR using components from Meler Giuing Solutions in Spain. Fully automated high volume binding lines, especially from Muller Martini and Kolbus, can vary block sizes and thicknesses with ‘zero makeready,’ frequently without stopping. These cost many hundreds of thousand pounds and take up a lot of floor space. Only the largest short-run high volume colour book operations could afford this, such as Harrier.

Large format books may benefit from the ultimate strength of thread sewing. For instance Smyth in Italy has sewing lines for digital books printed in pre-collated order. Its entry level Digital-88 (from £56,000) sold via Perfect Bindery Solutions is hand fed and takes flat sheets up to 640 x 520 mm, or pre-folded sections for huge books up to 510 x 550mm So, the equipment is there, the market is there in potential, but so far the economics don’t add up. Digital works well for nice thick beautifully produced books, but the costs are likely to keep them at the luxury level for the foreseeable future.