Pitney Bowes’ “print to mail” tag might not have caught on but the technology delivers

Ever since high speed full-colour inkjets became technically feasible in the late 2000s, the idea of ‘white paper mailing’ has gone from a concept to growing reality, says Simon Eccles.

The ‘white paper mailing’ phrase comes from the idea of starting with unprinted document paper and blank envelopes or enclosures, rather than the previously common method of printing black-only variable information on pre-printed coloured “shell” letterheads, one-piece mailers and envelopes.

It can apply equally to transactional and utility mailings as to more colourful direct mail promotions.

Ten years ago all the talk was of transpromo, ie bank and utility statements that would incorporate full-colour personalised marketing messages. That hasn’t really taken off, except for store card statements and offers, often with personalised coupons, taking advantage of dynamic perforating units.

Instead of transpromo we’re seeing more hybrid mail, where a big mailing house such as Capita or GI Solutions can put several documents from different customer sources into the same envelope, and then print them in mailsort order. Digital Printer reported on this at Capita’s advanced Mansfield site in the July 2015 issue.

Pitney Bowes’ concept of the White Paper Factory (which carries a trademark) certainly put the ideas into general circulation. It calls the same idea ‘print-to-mail,’ which hasn’t caught on so much. It works closely with HP, selling and supporting the T-series inkjets, which it renames IntelliJets, though there’s a wide choice of other suitable fast roll-fed full-colour inkjets from Canon/Océ, Fujifilm, Kodak, Ricoh, Screen and Xerox. All these companies work closely with paper transport manufacturers and downstream mailing system makers.

Pitney Bowes itself can configure inserting lines with roll feeds for digitally-printed paper, with bar code readers to synchronise document gathering and envelope printing; the latter can be a separate white paper roll with inkjet print-on-demand. PB can track every document and mail piece throughout the system. Last year it introduced the Clarity solutions suite, a SaaS-based system that can integrate and organise data collected from sensors on production mail machines to show real-time status, predictive analytics and prescriptive maintenance.

Other mailing system makers also offer white paper lines, or components to add on to other lines. CMC Machinery is a big name here. Its JWR system can start with blank rolls with an inline digital printer, or alternatively can feed pre-printed rolls. It forms envelopes that are wrapped around contents, then glue sealed and separated into individual mail pieces with a high speed rotary cutter. There are two models, for 20,000 and 30,000 mail pieces per hour. It can be combined with a separate roll- or sheet-feed line for digitally printed documents and synchronise the two, so that appropriate addresses are printed, a process that CMC calls One-to-One Envelope.

Bell & Howell’s Inveloper line handles the complete envelope-forming process from white paper rolls to finished and addressed mail pieces with insertion. There are two models, for either 20,000 or 30,000 pieces per hour.

Transport on a roll

Hunkeler and Tecnau are key vendors providing paper roll transport that links these production components, usually unwinders and rewinders or nearline systems, but with conveyors and bridging units for inline work.

Inserters on a white paper production workflow come in various configurations, but tend to be roll-fed with cutters at the input end, with folders, perforators, cameras and possibly inkjet overprinters.

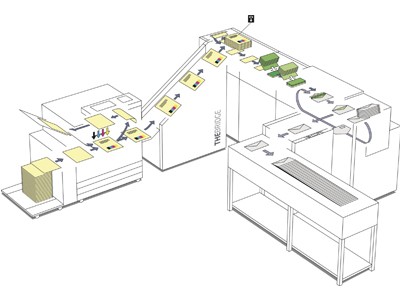

At a more modest cost and performance level, Böwe Systec has teamed up with sheetfed inkjet printer maker Riso on a white paper solution. It has developed a Bridge conveyor to take printed colour documents from the Riso ComColor 9150 X-Jet Pro A4 duplex printer into a Böwe Vario folder-inserter. This compact combination can handle window envelopes at a rate of 8200 pieces per hour. A downstream code reader and printer can add personalised full colour graphics to each envelope. The Mini Bridge system is similar with a lower-cost folder-inserter running at 4200 pieces per hour.

Böwe Systec and Riso have combined an A4 duplex printer with a folder-inserter via the Bridge conveyor

Any mailing line must ensure data integrity, so that the name and address on the envelope/wrapper matches that of the documents, and if hybrid mail is used that all the right pieces go in together. It is particularly important for anything financial, legal or medical to ensure that documents do not get put into the wrong envelopes.

In physical terms, data integrity assurance relies on cameras and/or bar code readers at important points on the line, with diverters to chuck out any “wrong-uns”, but verifying this and re-ordering replacements is handled well upstream by the document management software.

For example, AMS offers an add-on Read & Print system that will work with any of its inserters, combining cameras, Codesort software and an envelope printer. It works with up to four personalised documents enclosed in the same envelope.

Getting a handle on paper

Paper handling systems are vital to white paper mailing lines, especially unwinders, rewinders, sheeter-cutters and dynamic perforators. Hunkeler, Kern, Müller and Tecnau are significant players here. For instance, Hunkeler can offer configurations before and aft of a digital press that can be either roll-to-roll, roll-to-fanfold (some mailing systems still use punch hole tractor feeds), roll-to-stack and roll-to-sheet, each intended to work with nearline mailing solutions rather than inline.

Dynamic punching, vertical and cross perforation is performed by Hunkeler’s DP8-II-P punching and perforation module. Its CS8 cutting module produces full-bleed documents. Rather more exotically, Hunkeler also has a laser punch and perforating unit called HL6 that can change patterns from document to document lines running at up to 150 m/min two-up, on paper weights from 40 to 200 g/m2.

Kern offers unwinders and sheeters with much the same capabilities as Hunkeler and Tecnau. For instance the Unwinder 100 for the 3500 Inserting System runs at up to 240 m/min with automatic threading. Its top 999 high performance cutter can separate this into sheets at a rate of 80,000 two-up cuts per hour. Müller offers unwinders, rewinders, dynamic perforators and a card affixing system.

Tecnau (formerly Lasermax Roll Systems) offers similar roll-to-roll, roll-to-stack and roll-to sheet options, the last two with inline cutters. Unusually, it has a twin-roll feed with splicer for uninterrupted production. Its range of dynamic perforators include the top-end TC 1550 PLUS P unit, which offers dynamic punching and perforating with two to six independent cross-perforation devices, and two to four independent punching tools for two-up work. Its fast TC 8300 dynamic perforator can run at up to 240 m/min.

Over time, more and more mail is being printed digitally in full colour as a matter of course. In future attention will mainly be on software, for creating documents and monitoring results and “white paper” hardware will actually become the mainstream norm.

Read the full May issue here