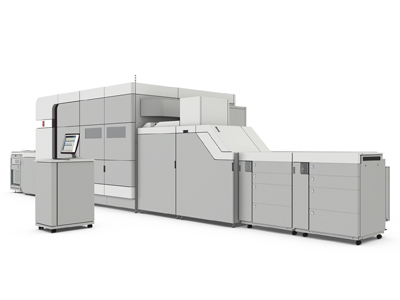

The sheetfed Océ VarioPrint i200 runs at 200ppm but can be upgraded to the 300ppm VarioPrint i300 specification

Fast, reliable toner printers have been the mainstay of most digital printing operations so far but is it time to pass the baton on to inkjet alternatives? Nessan Cleary investigates.

These days digital printers form the backbone of many print operations, able to handle the demands of different substrates and run lengths as well as personalised jobs. The dominant printing method is based around dry toner, which is a mature technology, meaning that even the simplest office multifunctional device is now a highly capable machine, with some able to match the sort of throughput that we expect from a production printer.

But we can reasonably expect a bit more from a production printer. Karl-Friedrich Edenhuizen, product manager for Konica Minolta’s Production Printing Group, says that office printers tend to have an all-in-one finisher, adding, ‘But a production printer in general is much more robust, with higher volume and the finishing is much better, such as a perfect binder.’

Consequently, the market is segmented into light duty machines, typically producing 65-80ppm, mid-range machines, with running speeds of around 100ppm, and heavy duty presses that can go up to 150ppm. The mid-range printers tend to be the most popular but there are plenty of CRDs and smaller printing houses using light duty machines, while the top-of-the-range presses will also offer other features such as spot colours or special effects in addition to sheer speed. Regardless, overall productivity is more important than speed, so look for features such as an inline spectrophotometer, which makes it easier to maintain colour through a run without stopping to check.

Another figure to look for is the average monthly volume that you can reasonably expect from a machine throughout its contract. It’s also important to look for peak volumes, which show the machine’s ability to cope with spikes in demand. The ideal should be to match the printer’s average monthly volume against the amount of work you expect to throw at it. The temptation is to buy a cheaper machine and squeeze more work out of it, but it may simply wear out quicker than expected, leading to more maintenance and unscheduled downtime.

Tried and tested toner

Kodak sells the Nexpress ZX, with a choice between the 100ppm ZX3300 and the 120ppm ZX3900, with an optional feeder that can increase the top speed to 131ppm and can produce sheets up to 1000mm long. It’s a mature system and there are quite a few extra options, such as dimensional textured effects as well as fluorescent and gold toners. Many components can be changed by the operator, which saves on downtime and allows companies to cut costs by using older components on lower quality jobs. The standard model takes coated and uncoated papers as well as synthetics and transparencies up to 350gsm but there’s an option to uprate this to 530gsm. The ZX3900 can handle a monthly duty cycle of 4.4 million pages.

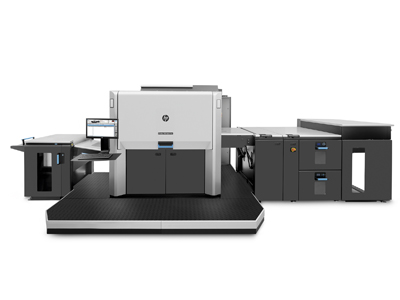

This HP Indigo 12000 is a B2 press, using liquid toner, and able to produce 4600 B2 sheets per hour using CMY or 1725 duplex B2 sheets using CMYK

HP’s Indigo printers cover a huge range of applications, from labels and packaging through to commercial printing. They use liquid rather than dry toner, which gives very good image quality at quite high speeds. They can support up to seven colours, though each additional colour slows the press down slightly. The extra colours can include spots as well as “effects” such as fluorescent inks or even white. The top of the range document printer is the Indigo 12000, which can produce 4600 B2 sheets per hour using CMY only, or 1725 duplex B2 sheets using CMYK. It takes coated and uncoated media up to 400gsm.

Xerox has an enormous range of toner printers, from small office copiers through to high volume beasts. The two most interesting series here are the iGen and the Versant. The current iGen 5 has a top speed of 150 ppm, though there are also 120ppm and 90ppm versions that can be upgraded to the faster specs as volumes grow. It has 2400 x 2400dpi resolution and there are options for orange, green, blue or clear toner alongside CMYK. It can handle a maximum average monthly volume of 3.75 million pages.

For the Versant 180, Xerox offers the sort of finishing options that we might normally expect to see with a more expensive printer

The Versant series includes the 3100 and the 180, both of which offer automated registration as well as advanced feeding capabilities for longer, uninterrupted print runs with inline finishing options including an inserter, and SquareFold trimmer. There’s also a Performance Package for the Versant 180 that includes Xerox’s Automated Color Quality Suite with an inline spectrophotometer for automated colour management.

Ricoh has a fairly comprehensive range of cut-sheet printers. The top of the range is the Pro C9100 series, which includes the Pro C9100 that can run at 110ppm and the Pro C9110 that can reach speeds of 130 A4 ppm, regardless of paper weight. These can handle a maximum monthly volume of up to one million A4 sheets. They can print onto uncoated, textured and coated media from 52gsm to 400gsm as well as speciality media such as super-gloss, magnetic, metallic, transparent or synthetic, with resolution up to 1200 x 4800dpi.

Ricoh also sells the C7100 series – a C7100 that can produce up to 80 ppm and a C7110 that’s capable of 90ppm. They both use the same imaging system, supporting media up to 360gsm and boast a maximum monthly volume of 240,000 A4 pages. Heidelberg rebadges the Pro C9110 as its Versafire CP and the C7110 as the Versafire CV.

There’s also the entry-level Pro C5200 series, again with two models, the C5200s and C5210s, which run at print speeds of 65 and 80ppm. They offer 1200 x 4800dpi, take media up to 360gsm and can print long sheets up to 1260mm. There’s a Fiery front end and various finishing options such as a booklet finisher with saddle stitching and folding capabilities, as well as an optional cover interposer.

Ricoh’s entry-level Pro C5200 series have speeds of 65 and 80 pages per minute

Konica Minolta has a number of Bizhub presses that are available in “Press” configurations for production environments. The flagship models are the Bizhub Press C1100, which runs at 100 A4ppm, and the C1085, which can produce 85 A4ppm. They take paper from A4 to SRA3 up to 350gsm. They use Konica Minolta’s Simitri HD E toner and have 1200 x 1200resolution. There’s a booklet making unit, perfect binding unit and saddle stitching kit and a choice of Fiery and Creo front ends

Canon has a number of sheet-fed toner printers, ranging from multi-functional office devices up to production printers. This includes the ImagePress C10000VP, a 100ppm colour printer that can handle a monthly volume of up to 450,000 A4 sheets. There’s also the C8000VP, based on the same platform but with a lower productivity of 80ppm. These can take paper sizes from A4 to SRA3, up to 350gsm, with 2400 x 2400dpi resolution. There’s a choice of front ends and several finishing options, including a saddle stitcher and a booklet trimmer for booklet production, as well as a perfect binder and paper folding unit.

Inkjet alternatives

For SRA3-format production printers, there’s a clear split between continuous feed, which is now mostly inkjet, while cut-sheet printers still use toner technology. Peter Wolff, senior director for Canon Europe commercial printing division, explains this, saying, ‘We are not developing toner continuous feed technology because inkjet is the one that is boasting highest productivity and full colour.’

For cut-sheet the arguments are more nuanced: inkjet presses are more expensive but they are also capable of higher speeds. Inkjets tend to have lower maintenance costs so it’s possible to avoid click charges, too. But the position of the media relative to the heads is critical to overall image quality with inkjets and this is much easier to control with a continuous web. Further, inkjet presses tend to be fussier about types of paper stock, whereas toner printers are able to cope with a very wide range of different substrates. For these reasons, most vendors are confident that dry toner presses are going to be around for a while.

Nonetheless, there are several sheet-fed inkjet presses. Canon sells two B3 models, the original VarioPrint i300, which was first announced two years ago, and the newer i200. The i200 is slower, designed as an entry-level press, but can be easily upgraded to the i300 specification. Both models use an aqueous pigment ink and can print to uncoated, coated and inkjet treated paper. They use Kyocera printheads printing at 600 x 600dpi but with variable sized droplets to produce an apparent resolution of 1200dpi.

Xerox announced the Brenva HD early last year. It’s meant for light direct mail, transactional and book printing. It can run at 197 A4 ppm and can handle up to 300,000 pages in an average month. It takes uncoated inkjet stocks up to 220gsm. Resolution is 600 x 600dpi with greyscale printheads. It has an inline spectrophotometer complemented by object-oriented colour management to distinguish text, graphics and images, and optimise each accordingly.

Xerox also sells the Rialto 900, which has a fairly compact footprint. It’s a roll-fed model but has an integrated finishing unit that cuts the web into sheets. It runs at 48m/min, which translates to 322 A4 ppm in single-pass duplex mode. It’s good for an average monthly volume of 5 million pages per month.

Clearly there is an argument that an inkjet press could replace several toner printers. But this depends on the target applications for each printing company. In book production, for example, some printers have switched to inkjet for book blocks, but are still printing the covers on toner-based devices. When it comes to cut-sheet printers, people tend to value the flexibility to choose the best substrate for the job and, for now at least, toner technology probably offers the best balance of high image quality across a range of substrates.

Read the full June/July issue here