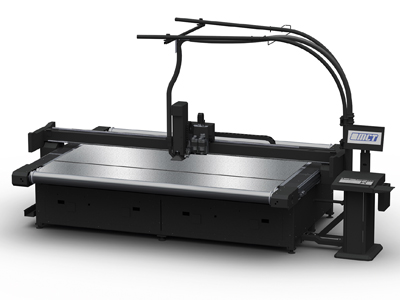

The VersaTech2 is a joint design and manufacturing effort from MCTdigital of the US and Essex-based Blackman & White

Cutting is one of the most basic finishing operations, needed in almost every job and just like the jobs it produces, the devices to do it come in all shapes and sizes. Michael Walker has his work cut out.

Almost nothing comes off a press at the desired size; even routine A4 flyers and magazines from “cut sheet” SRA3 presses need further cutting to reach finished size (and sometimes paper needs trimming to go into litho presses, too), while decals, signage and other wide-format graphics may need complex cutting out to yield shippable products. Then there’s perforation, partial cutting for applications like tickets and vouchers. No surprise, then, that cutting is probably the most common finishing operation. And for all the digital sophistication of the presses and the software that drives them, there are still really only two main ways to cut – with blades or with lasers. Even the routers for use on thick and solid materials printed on wide-format flatbeds use a type of blade.

It’s no surprise either that there is a wide variety of devices for carrying out the necessary cleaving, from guillotines and three-sided trimmers for sheet work to print-and-cut roll-fed wide-format machines to flatbed cutting tales and lasers capable of exotic filigree work that makes cutting a creative part of the job as much as practical necessity. If the basic mechanics of the process haven’t changed greatly, the productivity has, both in terms of physical make-ready through automation and overall throughput and accuracy through integration with presses and other finishing systems.

For the chop

For straightforward guillotining work, Terry Cooper Services (TCS) offers the CCM Premier range, which has CIP4/JDF connectivity at sizes from 780 to 1680mm, suitable for large-format work. Mid-range is addressed by the Challenge family which covers the range 508 to 670mm, with touch-screen programming, while the Graphcut range offers small footprint but with powerful hydraulic clamp and knife action at “competitive” prices, making it suitable for smaller print shops and the shorter runs typical of digital print.

TCS customer litho printer Colprint in Birmingham shares a CCM Premier 780 guilliotine with sister digital print company Set & Match, driven by the need to support shorter-run faster turnaround work in the digital operation. The unit was chosen for its robust build and touch screen set-up, allowing an existing guillotine to be moved in to the litho press area to cut paper for those machines, speeding work through those as well as in finishing digital print.

Rotherham-based security print specialist Secprint installed a Graphcut 52H to help with production of vouchers, tickets and security papers on Xerox, Ricoh and Develop digital presses. General manager Brian Terry comments, ‘Its ability to easily programme and store jobs makes us more productive. It has increased our capacity because we can now complete jobs much faster.’

Polar guillotines sold in the UK through Heidelberg include the Plus, N Pro and Eco series, which cover widths from 56 to 176cm, complemented by two versions of the Digicut laser cutting system. The most recent addition is the Polar D115, a hydraulic cutter for larger formats that’s suitable for both digital print shops as well as litho operations. Automation and JDF networking are being added to the Polar range’s capabilities via the company’s Compucut control system which allows jobs to be prepared and planned in advance; it can be combined with Heidelberg’s Prinect workflows to connect production, MIS and web-to-print. An optional addition to Polar units is the Guillo-crease system which converts them into creaser devices for a cost of around £800.

Colour touch-screen control makes arranging work a visual task on Polar’s guillotines

The Polar Digicut and more automated Digicut Pro laser die-cutters can cut, crease/score, engrave and perforate for production of bespoke stationery, greetings cards, menus, packaging, jigsaws and lanterns. They accept files from Coreldraw or Adobe Illustrator and can create products in paper, board, wood or plastic.

IFS offers both the Perfecta guillotine range and Horizon trimmers for book work. The Perfecta line has LCD control displays with soft-keys for creation and recall of cutting programmes, and a slotless cutting table that is designed to prevent the build-up of dust and paper debris in the mechanism. London trade print finisher and book binder Cliftons has taken two Perfecta lines to increase flexibility and remove production bottlenecks.

Managing director Tim Clifton explains, ‘Guillotining is such an essential part of the production chain and it is really important to get that right. Now we have two larger format systems we can be much more flexible.’

The Perfecta 115 guillotine line will cut paper, board, film and foils, rubber, leather and even sandpaper, in single sheets or stacked

On the trimmers side, the Horizon portfolio includes the HT-30, a three-sided trimmer that can change over in less than 60 seconds making it ideal for short runs and on-demand books. The HT-1000V is variable three-edge trimmer that can be run inline or offline and can read barcodes to set itself up for fully variable trimming, with each book different if required; running at up to 1000 books per hour, books of the same size can be stacked automatically. The HT-80 provides a JDF interface via Horizon’s pXnet bindery control software which helps to minimise downtime during makeready, reducing waste and increasing staff flexibility.

Duplo’s range includes guillotines, trimmers and booklet-makers (both stand-alone and inline), cutter-creasers which offer perforation and rotary die-cutters as well as the multi-function DC746IFS launched this summer (see September issue p53). An interesting development in terms of integration and automation with digital presses was the company’s participation with HP at drupa last year in a “Direct-to-Finish” demonstration where near-line integration of the DC-646i finishing unit with HP Indigo 7900 and 10000 digital presses was demonstrated.

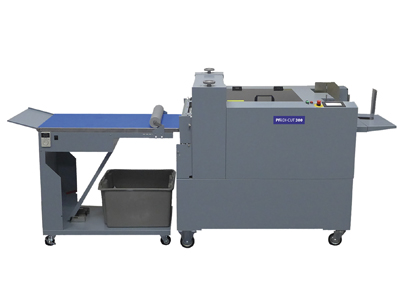

Duplo’s PFi DI-CUT 300 rotary die cutter can also kiss cut, crease, perforate, slit, hole punch and round corners in one process

This allowed the DC-646i to perform a range of finishing operations including cutting, perforating and creasing in a single pass, with automatic set-up via a job ticket created in HP’s SmartStream Production Pro workflow software. A further aspect to the electronic integration was connection between Duplo’s e-Tandem remote servicing technology and HP’s PrintOS cloud-based print production operating system. Real-time data fed from Duplo’s remote monitoring system can be combined into HP’s dashboard to provide a more complete overview of both print and finishing operations, that also extends to Duplo coaters, sheet-feeders and saddle stitchers.

Cards on the table

For those whose workload includes wide-format as well as regular cut-sheet press output, a flatbed cutting table may be a good choice. Morgana offers the Valiani Mat Pro Ultra models which provide working areas of 1215 x 815mm (model V120) and 1515 x 1051mm (V150). In addition to cutting they crease, perforate, emboss, plot, write and draw, with tool changes for the different applications being possible in 30 seconds or less.

Personalised whisky miniatures set cut on Morgana equipment at a recent Print2Finish event

There’s also the Valiani Optima range which includes the even larger V250. At 2520 x 1230mm it’s big enough to gang up 15 SRA3 sheets, and one has been in use at a Minuteman Press franchise in Bath since the start of 2017. Sales and marketing director Dave Dixon said, ‘Short-run packaging, shaped business cards, folders and flyers, plus signage work were the initial areas we had in mind, but we are already discovering a host of other possibilities.’ These have included cut tabs within a report and cut lettering from rigid PVC as well as test cartons.

Another digital cutting table is the Zünd G3, which comes in a variety of sizes, built around lengths of 1600, 2500 and 3200mm and five different widths from 1330 to 3200mm, with a variety of cutting tools for print and industrial applications, including a recently-added laser cutter for use in display and soft signage applications that cuts and simultaneously seals the edges of polyester fabrics.

One user of the G3 is signage and exhibitions graphics provider RMC Digital in Hull, which added a second and larger Zünd unit early in 2017 after the arrival of a new Durst flatbed printer created a bottleneck in its finishing department. The company uses the newer system to cut Dibond and ACM hoarding material via the 1kW router module and has also taken the upgrade to the G3’s creasing tool to allow foam board or card material to be folded. Operations director Nicole Spencer comments, ‘We have to react quickly to changes in demand, so having the second Zünd allows us to pre-press the job just once and we know it will be finished accurately.’

Rise of the robots

Automation is a big theme with Esko, whose Kongsberg wide-format cutting tables offer plenty of options, including robotic loading and unloading systems. Director of solutions management Jan de Roek explains, ‘Operating a cutting table can be a complex manual task. Job setup can easily take up to 30 minutes and result in hours of equipment idle time, especially when many short-run jobs, sometimes hundreds, must be processed each day. Finding the right cutting or creasing tool for a given material is not always easy, and quality often depends on the skill level of individual operators.

Leicester-based Data Image Group has reduced its lead times, improved management of short runs, reduced material waste and optimised equipment output following the purchase of a Kongsberg C automated robotic production solution with a Kongsberg Robotic Cell to speed loading and unloading. Director Robert Farfort explains, ‘Automation in our finishing department is really important to the future of our business. By automating loading and unloading of materials, we gain greater efficiencies from our cutting operation.’ The company also uses Esko’s Device Manager software to monitor job status as well as managing job queues for all connected devices.

Complete bundled systems including wide-format RIPs, printers and Summa cutting systems are offered by Art Systems. For flatbed cutting the Summa F1612, F1330 and F2630 offer various sizes of working area from 1.3 to 2.6m long, while roll-fed cutting capabilities come from the SummaCut D series and S-Class tangential cutters. Both types have a wide array of cutting tool options and according to Art Systems’ Andrew Edwards have ‘solid build quality and reliability’ without the ‘price premium’ of competitors. The company keeps the 1.6m model in stock for rapidly delivery and provides installation and applications support.

Beyond the cutter, Art Systems offers various software products from RIP developer Onyx, which allows cutting data to be sent to the cutter via the latter’s Summaflex Pro software so that the correct tool can be assigned automatically, as well as providing MIS integration for job tracking and costing. If the cutter has Summa’s barcode reading system, it can read codes, configure itself and cut all jobs in the queue without user intervention.

Winner of an SGIA award last year, the “all in one” MCTdigital VersaTech2 features full conveyor automation, including motorised roll unwinding or automatic board loading for all tools, including lasers, routers or tangential knives. Available in the UK through joint developer and manufacturer Blackman & White, the cutter is supported by tools for nesting and tiling at the artwork preparation stage, dedicated software for producing boxes and PoP/PoS displays, plus TigerVision’s machine control and vision capabilities. Other products in the Blackman & White portfolio include the Orion, Genesis and MasterCut ranges which feature flatbed and conveyor models.

Laser cutting of suitable large format materials is also possible with Trotec’s SP series which enable laser cutting with camera registration at up to 2210 x 3210mm. Both the SP2000 and the larger SP3000 offer access to all four sides and a Tandem Assist feature for loading and unloading work while the machine is running. Both models feature a fully enclosed laser so can be operated as Class II lasers without requiring additional safety measures; the SP3000 also has roll extension options with conveyors or an unloading table. The JobControl software is compatible with all major graphics design software packages.

Smaller cut-sheet work (with a cutting/marking area of up to 500 x 500mm) can be handled by the Trotec GS1200 which can swap between different jobs without tooling costs or much manual intervention. Productivity features include a flat pile input feeder and output sheet stacker, plus JobControl Vision camera registration software for throughput of up to 1800 sheets per hour. Other laser cutter options come from LasX, mediahouse, Hans Grohni and others.

Whether it’s business cards or point-of-sale, increased productivity and automation are the key trends in cutting, joining up this essential part of the finishing process with the production stages that come before and after; cutting is no longer cut off.

Read the full October issue of Digital Printer here. Subscribe to the magazine for free – register your details here.