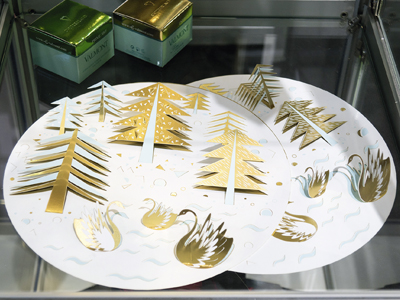

The combination of foiling and laser cutting with Highcon’s Euclid systems brings a new dimension to finished print

In the ten years that Digital Printer has paid attention to what we called “special effects” but the industry now tends to call embellishment, the range of effects has blossomed, while becoming more accessible. Simon Eccles brings us up to date.

Increasingly, digital embellishment is seen as a sales tool in a digital print market where basic CMYK is in danger of meeting the same commoditisation fate as offset. Embellishment effects might include spot clear gloss, raised and textured effects that resemble embossing, spot foiling that can be combined with raised effects to resemble foil blocking, white printing directly onto exotic effects papers and foils to give a show-through image, plus UV-fluorescing toners or films.

Some of these are intended to be eye-catching, for shelf appeal or the relatively new concept of “unwrapping appeal”, but the difficulty of scanning or photographing them also helps to deter counterfeiting. Here we’re looking primarily at embellishment for commercial digital printing, though it’s worth noting that some wide-format inkjets also offer metallic inks, fluorescents, and raised and textured clear inks.

Special inks as effects

Dry toner digital presses with fifth units usually offer spot clear, white and sometimes metallic or fluorescent colours, which can be used by themselves or in conjunction with other embellishment methods.

Opaque white inks are particularly important, as they can be printed over special effects media – especially metallised papers and foils. Holes left in the white image let the effect show through, while the white acts as a reflective undercoat for any full-colour printing on top.

The original digital effects developer was Kodak with its five-unit Nexpress 2100, now with the largest range of effects toners on current Nexpresses – improved gloss, raised Dimensional ink, plus metallic gold as well as security and special colours.

Xerox was next, with the Colour 800i/1000i presses that originally offered clear gloss and have since added metallic silver or gold. The Xerox iGen 5 has a fifth unit that runs white, clear or gamut-boosting colours.

Ricoh originally offered clear and white toners on its Pro C7100x series presses, (also sold by Heidelberg as the Versafire CV). Last year it added neon (UV-fluorescing) yellow and has just added neon pink (see p4).

HP’s current generation of liquid toner presses can have up to seven colour units so can handle multiple effects. White and spot clear are the main ones – there’s no metallic so far but there is a fluorescing pink.

Printing colour on top of white on top of metal foil, as in this Oki example, gives a novel luxury feel

You don’t have to spend a fortune to get five-colour effects. OKI’s range of compact long-A3 desktop toner printers include models with fifth units. In particular the long-A3 Pro 9541 prints CMYK plus white or clear on top, whereas the Pro 9542 can put white down as an undercoat below the colours. These models can print onto thick card, plus metallised substrates, up to 1321mm long. The clear gloss fluoresces under UV light. There’s also a specialised A4 model, Pro6410 NeonColor, which prints fluorescing CMY toners plus normal black or white.

Foiling

Foil-fusing systems apply heat that is selectively absorbed by black toner (or HP Indigo ink), so heat-activated hot foil sticks to it and peels off cleanly everywhere else. In the UK Caslon has long sold the US Foiltech range of dedicated manual or autofeed foil-fusers in formats up to 340mm wide, with prices starting at under £2000.

Vivid adapted its SRA3 format Matrix thermal laminators to work in much the same way, giving machines that could work as standard laminators as well as hot foilers. The Matrix can foil straight onto black toner print, or it can first put a clear protective laminate over normal print from any process. This is then passed through a toner printer then the Matrix can apply hot foil to the resulting black image in a second pass.

Vivid’s Matrix foiling machines provide a range of creative possibilities

You can also run foiled sheets through a toner press or HP Indigo press to get metallic colour on top of the foil – Digital Printer’s distinctive front for the October the issue was produced by Vivid using this method. Vivid has an exclusive deal with Color-Logic, developer of software for creating metallic colour palettes that can be imported into standard design programs.

Other thermal lamination systems have also been adapted to apply hot foil over toner or Indigo ink. For example GMP, a Korean laminator maker, sells a foiling system it calls ‘sleeking,’ now available on six of its laminators from wide format to sheet-fed B2+ formats. This puts metal/solid foil onto black toner or clear high gloss over colour. The UK agent is GMP UK, and Intec Printing Solutions also sells four models as part of its own Colorflare brand name.

At drupa 2016 Leonhard Kurz, a large German metal foil manufacturer, showed DM-Liner Toner, a self-standing machine that applies metal foil over black toner or HP Indigo ink print as with similar rivals. There are B2 and SRA3 models and one of each size has now been installed in UK customers. The B2 speed is 2400sph.

Kurz also talked about DM-Liner UV-Ink, a 390mm wide inkjet model that prints UV-cured clear ink over pre-printed media and applies cold foil over that. Autobond offers a hot foil unit for its thermal laminators, but can also fit a cold foil system inline with its SUV clear UV varnishing inkjet unit.

At drupa last year, MGI announced Unlimited Colors, an option that puts a hot foiling unit inline with any of its current MGI Meteor sheet-fed toner presses for sheets up to 1200mm long.

Last year Landa showed a new digital technology called Nano-Metallography, which applies metal particles to a printed varnish. This process has now been sold to investor Altana, which is commercialising it via a German company, Actega Metal Print, under the new process name EcoLeaf.

Digital embossing

Kodak’s Dimensional clear dry ink for its five-unit Nexpress models was announced at drupa 2008 and is still available on today’s models. This produces a raised and/or textured image up to 28 microns high. No other toner press can do this. However, HP introduced a multi-layer raised image facility for some of its liquid toner Indigo models in 2012. This can build up ink by multiple passes of the impression cylinder, but each pass counts as a chargeable click, so raised images can be expensive.

Dedicated spot clear inkjets can apply thicker, higher-gloss clear UV ink. The first to be announced was the MGI JETvarnish at drupa 2008, which went on to be developed into a range of models with different sizes and capabilities. These include the B2 JETvarnish 3D Evolution, which can create raised and textured embossed effects and can be combined with an inline foiler. A smaller B3 format 3DS for long B3 sheets (up to 364 x 1020mm) is sold exclusively through Konica Minolta.

Scodix first showed its raised 3D system at Ipex 2010 and today’s models can apply up to 250 microns of clear coating. Foiling, glitter powder and other effects can be applied. The range starts with the B2 S75 and progresses to the forthcoming high speed but high priced E106 for the ‘industrial’ carton market, currently in Beta.

Earlier this year Duplo launched its DuSense DDC-810 Sensory Coater. This prints clear UV spot varnish with the option of raised and textured finishes. It takes long B3 sheets up to 364 x 740mm.

Filigree finish

Distinctive finishing effects can also have a huge impact. Laser cutters in particular can create fantastically elaborate, fine cuts referred to as “filigree”. This can’t be done with conventional metal rule dies or digital cutting tables.

There’s quite a choice of auto-feed laser cutters which achieve high throughput by moving sheets (or rolls) continuously under the laser heads. Established models include the US LasX Lasersharp models which are nominally B2 and can run inline with digital presses, knife folders and robot stackers; the German mediahouse motioncutter, a belt-fed B2 model again with inline options; and the Austrian B2 format Trotec Laser GS1200 that includes a flat pile feeder, automated paper path and sheet stacker.

There are also China-built Hans Gronhi LC models distributed by Printers Superstore. Models include the LC340S (autoload 483 x 340mm); LC660S (autoload 660 x 470mm); and the manual feed 660 x 470mm LC660T.

If quantities are small, you might consider a cabinet or table-style hand-fed laser. Epilogue, HPC Laser and Trotec are major names here, offering machines from entry level small formats up to 2210 x 3210mm for the largest Trotec SP table. You can dip your toe in the water with a £1920 HPC LS3230 LSCT desktop A4 model, or pay even less if you want to risk a cheap Chinese model from eBay. Polar, best known for its guillotines, sells the hand-fed B2 DigiCut at about half the price of an autofeed model.

What lasers can’t do terribly well is crease: at best they score by half-cutting. One solution (used by LasX) is to run inline with pairs of digitally-controlled knife folders, but Highcon Euclid models can form true creases alongside laser cuts. The company currently supplies three models, primarily for folding carton work: the B1 format Euclid III (recently speed-bumped up to 2250sph), B2 Euclid IIIS (2750sph), the high speed but pricier B1 Euclid Beam (5000sph) and the B2 Pulse (2000sph).

Whether it’s clear or fluorescent inks, textured builds, foiling or fancy cutting, there are many routes to adding effects or “embellishment” that give digital print an edge over other digital media, and add value to both the end-user and to the printer.

Read the full October issue of Digital Printer here. Subscribe to the magazine for free – register your details here.