Digital Printer explores the benefits of enterprise software systems as drivers of profitability – and success.

In an economic landscape of tighter margins, rising costs, and a growing skills gap, printers are being forced to rethink how they operate – and more importantly, how they manage their business intelligence. Enterprise resource planning (ERP) and management information (MIS) systems, long seen as back-office admin tools, are stepping into the spotlight as enablers of lean, responsive, and more resilient print businesses.

And with user-centric cloud-native platforms, real-time analytics, and AI-enabled features now joining the conversation, the implementation pain once associated with “enterprise” systems is finally starting to fade.

The case for smarter systems

For Lee Ward, managing director of Tharstern (part of eProductivity Software) and product owner of Nubium, the power of a modern MIS solution lies not just in efficiency, but in the way it uses its data.

“You could argue any business that hasn’t got a handle on what its costs are, where it could save, and where it might be better off spending its sales efforts, is putting itself at risk,” he says. “Margins are being squeezed on jobs all the time with raw material and costs going up. So, there must be other ways to increase profitability.”

A properly implemented MIS, Mr Ward explains, does more than just automate quotes or process orders. It helps businesses “analyse what your business is doing and where your strategic direction should take you.”

“In my experience, I see a lot of printers implement MIS, but not necessarily interrogate the data that it can give you comprehensively,” – Lee Ward, managing director of Tharstern

That kind of joined-up thinking is particularly valuable for printers facing the twin pressures of economic uncertainty and a skills shortage. According to the Office of National Statistic, between 2006 and 2021, the number of skilled professionals in the print industry declined by 73%. “So, people need to have tools and systems that are simpler to run and easier to implement,” says Mr Ward.

Data as a strategic asset

One of the most overlooked aspects of MIS adoption, according to Mr Ward, is that many printers fail to interrogate the data these systems can generate.

“In my experience, I see a lot of printers implement MIS, but not necessarily interrogate the data that it can give you comprehensively,” he says. “It’s almost like its own topic in its own right – business intelligence and strategic thinking around the data that you’ve got.”

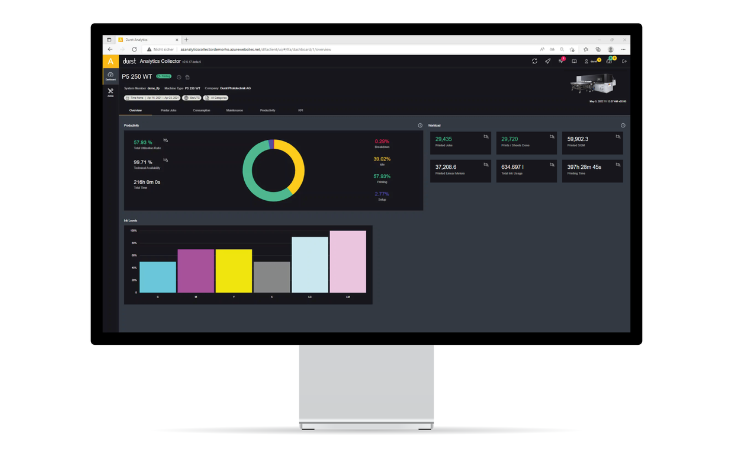

This sentiment is echoed by Durst, whose Lift ERP and Durst Analytics platforms aim to bring operational data into sharper focus. “Durst Analytics transforms operational data into a strategic asset,” says Christian Schowalter, head of global sales at Durst. “It enables data driven decisions that enhance equipment uptime, streamline maintenance planning, and improve overall production efficiency.”

Lift ERP offers detailed job lifecycle tracking, accurate job costing based on substrate, ink, and machine specs, and real-time production oversight. For Durst customers, it’s an antidote to disconnected spreadsheets and manual data re-entry, replacing them with “a single, intelligent platform.”

Unified software as an economic driver

Minna Philipson, CMO of Gelato, believes that the fragmentation of the print industry makes smart software even more crucial. “We actually did a study with McKinsey on this, interviewing 100 printers, and on average they have four software tools,” she says. “So, they’re paying four software fees and then they’re also paying to kind of plumb them together, however ineffectively, in their own facility.”

That cobbled-together approach leads to inefficiencies, risk, and cost. “Modern software comes at a source fee that you know will significantly undercut the costs that you currently have,” she says. “Almost every one of our customers report back a wide range of different types of savings,” she adds. “That can be savings on logistics costs, it can be better prices on procurement, cuts of 50% in packaging time, a decrease in 30% in waste of paper… and all of these things they add up.”

Nubium puts actionable data within easy reach for PSPs

In other words, software is not just an operational convenience – it is a multiplier of margins.

Real-rime responsiveness

Where older ERP platforms offered static reports and rigid processes, today’s cloud native tools are dynamic, responsive, and scalable. Durst’s Analytics dashboard, for example, offers live monitoring of job progress, errors, and production volumes. Historical metrics allow for performance benchmarking and preventive maintenance, helping operators spot trends before they become problems.

Similarly, Nubium from EPS is designed for agility. “It’s a new technology that’s kind of been in development for five or six years,” Mr Ward explains. “True cloud technology that’s very intuitive to use and very intuitive to implement.”

That last point matters. Historically, one of the biggest barriers to ERP adoption has been implementation time. “It’s like open-heart surgery to any business,” Mr Ward says. “When you’ve got to take out what you’re previously using and put something new in, it’s always a really difficult job to convince people to move away from it.”

With Nubium, EPS has tried to reduce that fear factor. “Typically, for most MIS or ERPs you’re talking about six, nine, or even 12 months implementation time. With Nubium, you’re talking days and weeks as opposed to months.”

Nubium includes “smart help” tools that guide users through con figuration without needing expensive consulting time. “It reduces the amount of time it takes to implement, but also the cost in terms of implementation because you rely on the customer to be self-sufficient,” Mr Ward adds.

Preparing for disruption

Ms Gelato’s Minna Philipson sees software as not just an efficiency driver, but a survival strategy. “The print industry has not yet been disrupted, but it can’t be far away,” she says. “It’s an industry that’s facing a generational shift, and the people that are coming in – perhaps looking to take over the family business – will be looking at new ways of doing things.”

She compares the current state of print to other sectors like hospitality or taxis – industries transformed not simply by hardware, but by platforms. “You look at other manufacturing industries and some have achieved over 99% automation. The print industry is sort of hovering around the 50% mark. You just think – what if you could be completely automated? What if you could run your entire business on one piece of software?”

Lean, automated, and resilient

What emerges from EPS, Durst, and Gelato is a shared belief that enterprise software is no longer a luxury – it is a necessity. From automated inventory and procurement to AI-supported data analysis and live production dashboards, ERP and MIS platforms are helping printers stay lean, agile, and pro table.

The goal is to do more with less. To gain insight without spreadsheets. And to adapt quickly in an industry that’s increasingly shaped by automation, online ordering, and shrinking job run lengths.

As Ms Philipson puts it: “Change is always scary, but I think for this industry it’s also an enormous opportunity.”