John Brailsford Printers has become the first UK print business to install a Morgana ColorCut SC6000 digital die-cutting and creasing machine, debuted by Morgana at the 2023 Hunkeler Innovationdays.

The ColorCut SC6000 is a free-standing, on-demand digital sheet cutter and creaser, with no physical cutting dies or set-up costs. It is targeted at those seeking an affordable, high-capacity device, capable of unattended cutting.

John Brailsford Printers, a Rotherham shop-fronted business, reviewed several potential products. Company owner John Brailsford remarked, ‘We had looked at a variety of potential solutions, but nothing was quite suited to our needs. Either they were too expensive, were overly complex, or they still needed dies to be produced. The previous Intec machine, the SC5000 was close, but not quite large enough to handle the range of stock that we needed to process. We thought we were just going to have to stick to outsourcing any work that required die cutting.

A call from Ray Hillhouse at Morgana introduced the SC6000 to Brailsford, which overcame the limitations of the smaller model. The SC6000 is a hybrid automated cutter that blends flatbed and sheet-fed technologies, to give a maximum working area of 340 x 710mm, plus a range of updated features.

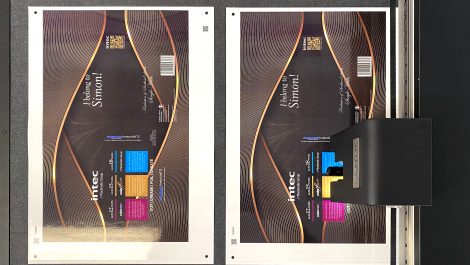

Mr Brailsford added, ‘We introduced the SC6000 to our studio people initially. They were able to easily understand the ‘front-end’ of the machine. The output from the studio, including cutting requirements and run length, is encapsulated in a QR code, meaning that all the people at the post-press end of the factory need to concern themselves with is selecting the right stock and scanning the QR code printed on the job.

‘This machine is quite amazing. The results have been quite superb. We keep thinking up new ways of using it – with labels, for example, we are now running through our stock of pre-cut labels, and then we can simply use the SC6000 to kiss-cut the labels for us on plain adhesive-backed stock. That means any sized, or shaped, self-adhesive label is possible, and we don’t need to have the expense of holding any stock of various sized at all.’

Mr Brailsford said, ‘The feeder is a critical element for such a machine, and this one is amazing! It will feed virtually any stock, it seems, eliminating any static issues, and the potential for any doubles.’

Accordind to Morgana, particular attention was paid to the feeding system to ensure good performance levels for card, vinyl labels, or even laminated sheets. The SC6000’s auto feeder accepts up to 900 sheets, raising or lowering as required.

‘We had been sending work such as short-run boxes, pocket folders, and various other cut-outs, to an external supplier. That kind of work has definitely been on the increase, so this really was the right time for us to bring such tasks in-house – it’s going to cut our outwork bill significantly, and therefore will pay for itself in no time,’ added Mr Brailsford.