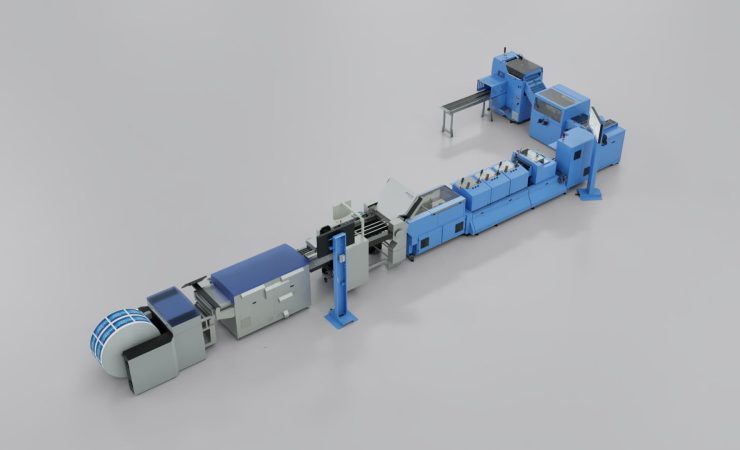

Müller Martini has launched Prinova Digital, a 9000cph roll-fed saddle-stitching line that it describes as an entry-level model for binding both digitally and analogue-printed magazines, brochures and catalogues.

The company says the new system, which was demonstrated at the Hunkeler Innovationdays event at the beginning of March, offers a hybrid solution for products printed digitally, analogue or by a mixture of both, and can support runs lengths down to one. It features a redesigned pass-through folder which provides the link between the digital feeder and the saddle-stitcher. Its new operating technology is complemented by an Asir Pro camera for code reading and/or image comparison, and a completely new infeed that can now also be equipped with creasing.

The stitching machine adapts to the product thickness and controls the stitching wire length fully automatically from product to product. The automated wire feed gear has now been installed outside the stitching centre, improving operability and accessibility. The three-knife trimmer also adjusts automatically to the product thickness. Cutting takes place with the product stationary, for higher cutting quality.

The Prinova Digital’s has a new user interface with context-sensitive displays and an ‘innovative operating concept’ claimed to shorten processes, via a large touchscreen; up to two external screens are supported for displaying production data. In digital production, the workflow view shows the next job on the reel, which formats are pending, or whether wastage has occurred.

The redeveloped feeder section uses individual feeders with servo drives, with up to 14 individual feeders enabling hybrid production. This can be managed by a single operator thanks to a high loading height, and can be tilted, enabling several application options at the same time, such as manual loading or setting the optimal discharge height for signatures.