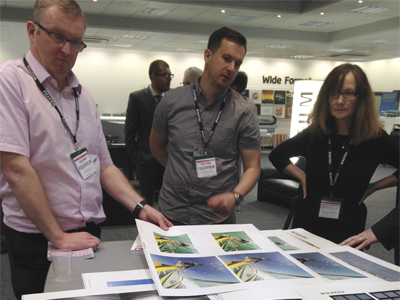

Full-gamut printing on the JetPress 720S gives more vibrant primary colours than available with offset

A series of open days and individual company visits has seen Fujifilm’s JetPress 720S B2 inkjet demonstrated continuously this month and are likely to have secured at least one sale.

The last three Thursdays have been JetPress open days at Fujifilm’s demonstration facility in Bedford, drawing in 120 people in total, and every other working day this month has hosted company visits as part of a campaign to demonstrate the B2 inkjet press to customers and prospects.

The demonstrations showed how the JetPress 720S, which combines a Ryobi chassis with Fujifilm Samba printheads and is driven by a high performance scalable RIP based on the APPE Mercury architecture, could image one side of a B2 sheet in 1.3 seconds. While slow compared to typical litho B2 press performance, that does allow for every sheet to be different – as when collated calendar or book jobs are printed, for example – and at a quality that in some aspects surpasses offset.

JetPress solutions manager Steve Freeman explained how for very short runs the near-zero make-ready time of the JetPress meant that its 2700 sheets per hour speed could be maintained even when running different jobs back-to-back. A barcoding option ensures correct front/back matching in work-and-turn operation, including anything with variable data content, across as many jobs as required.

Wide-gamut printing was also demonstrated, showing how more vibrant colours could be printed as an alternative to matching typical offset standards such as Fogra 39. Mr Freeman said that around 80% of Pantone colours could be matched, compared to 55 to 60% for standard four-colour offset, and that it as possible to match these while maintaining Fogra standard colour for other content in the same job. He showed how the press could yield impressive results on cheaper stocks, matching litho print on an expensive uncoated paper, or even able to provide better colour intensity, thanks to the way that the inks sit on the primed paper rather than sinking into it.

In addition to showing packaging work on light cartonboard, Mr Freeman said that customers had shown interest in running back-lit and synthetic media. The determining factor for this is whether the media can withstand the heat in the dryer section without cockling; Fujifilm will test media at its Brussels site to confirm this.