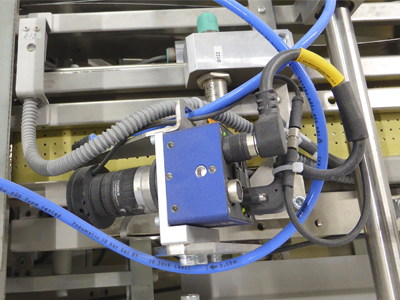

The camera technology supplied by Matrix Vision makes monitoring of folded production on the Le Mans system a safe exercise for MBO’s operators

To check and adjust the sheets being processed on its Le Mans folding system without removing the noise hoods that protect the operator, MBO has installed an industrial camera manufactured and supported by Matrix Vision.

At its maximum, the fully automatic Le Mans folding system manufactured by MBO can produce up to 23,000 A4 folded sheets per hour.

Three cameras are required to monitor the parallel fold, cross-fold and three-fold processes that can be performed on the system. The requirements for the system were also quickly established, and in addition to traceability in the event of faults, the safe monitoring of on-going production was also important.

In operation, software displays live images from multiple cameras simultaneously as thumbnails that are continually refreshed. When the operator selects a thumbnail an enlarged version of the image is displayed at the correct refresh rate. In addition, the operator is able to view the last few seconds of production in slow motion if required.