Imprint’s installation at MRP will track a wide range of in-house print and finishing operations

Nottingham-based Midland Regional Printers (MRP) is installing an Imprint MIS-based system to handle multiple job types from commercial digital to labels and packaging.

The project has been in development since a meeting between MRP and Imprint at The Print Show in 2015 and has now come to fruition as an approach to handling the diversity of the former’s workload has been developed.

Stephen Bates, managing director at MRP, says, ‘The three main reasons we chose Imprint were firstly, the multiple function estimating – our estimators are dealing with hundreds of estimates a week; one could be for 1000 four-page A4 brochures, the next for 50,000 bespoke labels and the next one could be 5000 bespoke carton bases and lids. To be able to produce quotes within the one system will save us masses of time and make the department far more efficient.

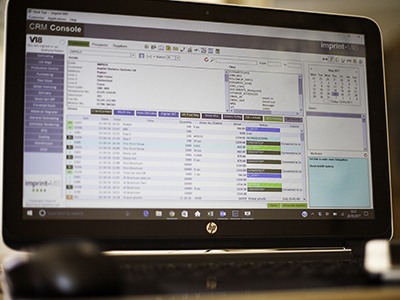

‘The second reason is job traceability. The production planning board is very easy to use and with shop floor data collection the whole company can see exactly where a job is in production, all from their desks. And thirdly was the flexibility of the system. We want our MIS to work the way do and not have to change the way we work to suit the MIS, and Imprint will do exactly that.’

The Imprint solution supports multiple job bag formats to address the differing production requirements and will provide live updates via its Production Control interface, fed by shopfloor data capture and SentinelNet machine monitoring capability. A job record card system will help support the large volume of repeat jobs at MRP. Installation began in July and the system is expected to be fully live later in the autumn.