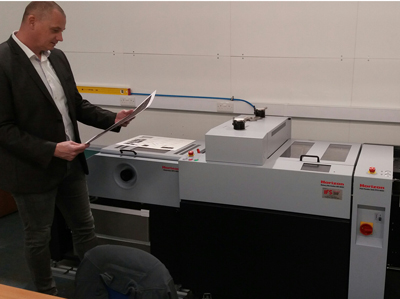

SML Corby’s Julian Wall with the Horizon RD-4055

SML Corby has installed SML Group’s 15th Horizon RD-4055 worldwide. Supplied by Intelligent Finishing Services the system was chosen to unify RFID tag and label production and increase productivity.

The Horizon RD-4055 was identified by SML’s head office as the part of its global procurement strategy established to ensure global production quality is consistently maintained.

The company works with numerous household names including Next, Tesco, Matalan, Burberry and the Arcadia Group. It produces short to medium runs on an HP Indigo and two Konica Minolta Bizhubs.

Julian Wall, operations manager at the Corby plant, said the decision to invest was prompted by three drivers, ‘We were winning more and more orders for RFID tags and labels and our flatbed system was very labour intensive. Also, we had a fire in July and moved into a temporary building. Since then we have been phasing in new systems.’

The RD-4055 is designed to meet the growing demand for short run die-cut products. Running at a speed of up to 6000 cycles per hour, it can die-cut, crease, perforate, slit, hole punch and round corner in one process for digital and offset printed sheets up to 0.5mm.

Its repeat-register function enables the running of multiple up imposed applications with a smaller die to reduce die cost (Up to 5 repeats in a single pass).