In an exciting endorsement of the local textile printing market, Kornit Digital has established a UK entity devoted exclusively to serving the British market, the largest in the EMEA region. Charlie Kortens sat down with the company’s EMEA managing director, Chris Govier, to find out what this means for Kornit, the country and the wider textile printing market

The British textile industry remains the fifth largest in the world, worth more than £9 billion per year. The nation’s online retail sales are also going from strength to strength, now being valued at more than £76 billion per year, making the UK the world’s third-biggest e-commerce market, after the USA and China.

No wonder that Kornit thought the time had come to solidify its presence on these shores. ‘The UK market is the largest within the EMEA region,’ said Chris Govier, who became Kornit’s EMEA managing director in April 2019. ‘We expect further acceleration across the region and the time was right to set up a UK office that would bring us closer to our customers.’

This in particular is key for the company, as Mr Govier explains, ‘As a start-up company we had a partner network across the EMEA region which we utilised as we grew. This included a partnership with Adelco, who had represented us in the UK for 17 years, but our growth plans simply didn’t match any more. We are both customer- and market-driven and an integral part of our global growth strategy is getting closer to our customers.It should be noted that our other UK partner, Amaya remain a key part of our go-to-market strategy here in the UK to give us depth and reach across the market.

‘As part of the new UK operation we can now invoice and bill in Sterling and will be offering a British distribution hub for inks and consumables. This will be based in the middle of the country, near Coventry, allowing us to offer same-day delivery.’

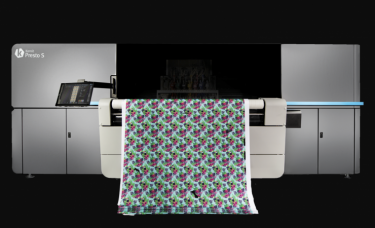

Kornit’s 10-channel Presto textile printer, to which the company added a ‘dry digital softening process’ earlier this year

The pandemic

Of course no discussion of growth strategies can be complete without discussing that largest of elephants in the room, the Coronavirus pandemic. Mr Govier was understandably careful with the words he used to explain, ‘With the virus… globally it has accelerated and increased trends we were already addressing. Shopping malls and the high street, any retail in bricks and mortar, has gone through a meltdown. At the same time e-commerce has boomed and, correspondingly, investment has increased.

‘Companies that already have established e-commerce capabilities have been inundated with orders and I feel this has been a real inflection point, changing the way firms look at their offerings. In fact, in a three month period from March to June we saw a growth rate in the US and Europe equivalent to the previous 10 years of ‘normal’ trading.’ The managing director points out that this shouldn’t be too surprising as, unlike many aspects of commercial print, the demand for clothing won’t be affected by the pandemic or lockdowns.

One side effect of the pandemic which Mr Govier said has had an impact was the postponement of a slew of industry events. ‘Exhibitions were a crucial platform for us,’ he says. ‘It was always great to have attractive technology on a stand. Still, we’ve worked in a different, virtual way and are confident we can maintain that momentum.

‘There will be plenty of products to come, along with enhancements as we test systems in the actual marketplace so look out for new developments early next year. There will be further innovation with things like the Poly Pro platform, for printing onto polyester such as sportswear, where we are really pushing boundaries.’

Customers

So who exactly are these customers that Kornit is so keen to get closer to? Is there a large amount of overlap with other digital printing markets? ‘We generally look at this in two ways,’ Mr Govier continues. ‘First of all there is the direct to garment (DtG) sector, which comprises personalised shirts, hoodies and the like. Then there is direct to fabric (DtF), which is a market we are relatively new to, but where we are seeing big changes now being addressed by brands and designers.

‘In all the areas we work across, run lengths are dropping and we have the benefit of no minimum order quantities. At Kornit we are convinced that if we can capture this transitioning market, these customers will be ours for some time’

Mr Govier suggests that there is plenty of scope for Kornit to work with printers looking to move into the textiles world, as well as for people already involved in textiles to add digital capabilities. ;There are plenty of commercial printers that already have the online elements in place,’ he says. ‘Think of promotional printers, their client base is almost a captive audience, so all they have to do is add new DTG products to their offering.

‘Similarly digital printing offers huge potential for people working in textiles and they are becoming more and more aware of this. They know that customers are moving away from the high street, are now looking online and the short runs, personalisation and environmental advantages of digital are all huge selling points.’

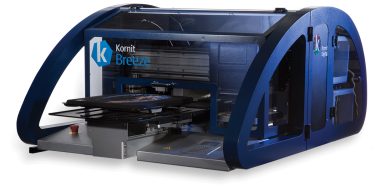

Kornit Breeze is designed specifically for small to mid-sized digital T-shirt printing businesses, online and retail shops

The Zedders

Mr Govier, who built his reputation over a long and distinguished period with Xerox, explained how the shopping habits of young people in particular are driving change in textiles markets. ‘Gen Zedders are way, way ahead of the curve,’ he expounds. ‘They aren’t necessarily concerned with technology, they care about standards and credentials. Is the cotton ethically sourced? Are labour practices moral? We’ve seen from the growth of veganism and concerns about sustainability that young people are often prepared to pay up to 15% more to do the right thing.

‘Just look at platforms like Tik Tok and extrapolate where young people are headed. A twenty year-old designer with an interest in sustainable production can build their own following online. They need local, sustainable and ethical production and manufacturing to complete their value proposition and so our job is to connect the dots and help build the end-to-end eco-system. We are on the verge of a whole new way of doing things in this sector.

He also adds that younger customers, rather than valuing fashion trends in the manner of previous generations, prefer custom garments and designs that are unique to them. ‘Previously, retailers used to order products a year, 18 months, even two years in advance, but that sort of supply chain has collapsed – exacerbated by the pandemic. As part of this, companies are onshoring production, meaning products that used to be produced elsewhere in the world are being made in countries like Britain again, as this allows for such a fast turnaround and an ability to be dynamic and react to consumer demand.

‘Obviously, some clothing will still be made using traditional methods and practices, but it is the ability to personalise and customise and ultimately self expression that will be driving demand going forwards.’

Sustainability

The environmental sphere is another area where Kornit believes it can offer customers unique value. ‘Digital can offer huge environmental benefits and we are very green in terms of our credentials,’ Mr Govier says. ‘We don’t use acids or add to water pollution. Our systems aren’t designed to make products and then to sell them so there are no wastage or landfill issues. Instead they allow our customers to sell applications and then to produce them.’

These are all key selling points for Kornit as its customers, and everyone in the textiles sector more broadly, are looking at being more responsible and are aware that the textiles/fashion industry is one of the biggest polluters in the world. ‘Water consumption and wastage is phenomenal in the textiles world,’ Mr Govier adds. ‘Chemical usage causes untold problems and when you think about the shipping and freight impact, it’s horrific.

‘Part of the reason clothing production is coming back to the West is the wastage from products that just aren’t needed. About 30% of clothing produced is never sold, often heading straight to landfill, and the 70% sold obviously retails for a higher price to make up the difference. Another reason is concerns over labour practices and I wouldn’t be surprised to see designers, printers, brands and manufacturers all move toward being more responsible and even offering open costings in the future.

‘Kornit is in the vanguard of a change to a greener, more ethical industry and giving consumers and that choice.’

The Kornit Avalanche Poly Pro, the company’s ‘game-changer’ for printing polyester

Excitement

Of course the interview couldn’t possibly have been called complete without finding out what aspect of the textile printing market Mr Govier is most enthusiastic about. ‘There are loads of exciting aspects to the market,’ he concluded. ‘There are a cluster of companies based around Lake Como pushing the boundaries of personalisation driven by our technology. As a result, high-end brands like Gucci and Louis Vuitton are looking seriously at digital and how it can add value to their brands and customers whilst moving to a more sustainable way of working. As this continues, others will follow.

‘I think DTF is creating a huge opportunity for us. Turning existing processes and methodologies on their head is a real game changer. Sustainability is here to stay, brands and fashion retailers need to address this growing concern for their customers and governments need to prioritise how they set standards and provide clarity for the consumer. We really can help to bridge the old world and the new. Brands know they need to change, and the advantages of digital will eventually lead to a tipping point where the floodgates will open and then we won’t look back.’ There are exciting times ahead.