CMYUK has sold Kongsberg X24 Edge cutting tables to Kazoo Print and Mailmate, with the latter also taking a pair of Mimaki printers, a roll-fed UCJV300-160 print-and-cut machine and a JFX200-2513 EX UV LED flatbed.

Jersey-based Mailmate initially sought only the cutter to expand the display side of its business, but after its market research had led it to CMYUK’s Shrewsbury showroom, a re-evaluation of Mailmate’s production led to the decision to buy the JFX200 flatbed for direct to board printing and to facilitate a move away from solvent inks. The 1.6m UCJV300 print and cut machine was added to further improve application diversity.

Product support was part of the decision for the Channel Islands printer, which in the 30-plus years since its founding now provides the widest range of print and mailing options in the islands, including marketing services ranging from database management to storage and logistics.

Managing director Neil Faudemer commented, ‘The world is a very uncertain place now, and it’s all about being able to offer a broad range of services. We are finding lots of crossovers – someone may come in for a banner but may then ask for T-shirts and business cards for example, and we can do the lot. We’ve never been frightened to invest in new technology and the evolution of our business over three decades demonstrates this. We moved into wide-format digital printing six years ago, and we also have a heat press and an embroidery machine in-house, so textile printing is also something we offer, which is particularly good for the sporting and charity events that take place on Jersey.

‘Our experience with CMYUK has been a very positive one, and we are looking forward to continuing to build the relationship and working with them more closely.’

The same model cutting table was also bought by. Staffordshire-based Kazoo Print, a business that caters to high street brands, working in a 70/30 trade and direct service split. The Kongsberg unit joins existing EFI Vutek roll printers, also bought form CMYUK, and an existing Zünd cutter. It was added tor elieve post-print bottlenecks that arose thanks to the acquisition of new business during the lockdown periods.

Kazoo managing director Simon Talbot explained, ‘I took the gamble of installing the EFI Vutek GS 3200 in March last year, ready for that influx of work that I was expecting. In the middle of 2021, it all kicked off as I thought it would, and we were super busy. The second six months of last year we matched our pre-Covid turnover, and this year we’ve exceeded our pre-Covid figures by a long way. Our latest Vutek printer [a QS2 Pro] is 10 times faster than the one we swapped out. We’ve had lots of print going through and the Zund just couldn’t keep up with it all.’

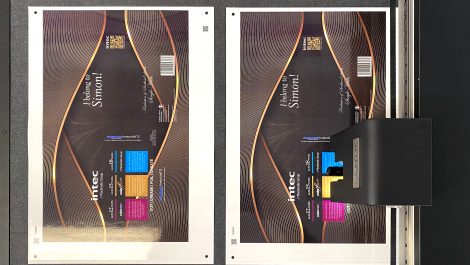

Kazoo Print opted for the Kongsberg model with the MultiCut tool head, which offers greater milling productivity, a camera for accurate registration, and QR code support that enables automated workflow for more efficient throughput. The latter has allowed staff to progress to new roles within the business, and two new staff members – pickers and packers – with no machinery experience who wanted to work with the new cutter were included in CMYUK’s Kongsberg training.

‘They jumped onto it easily. The QR code automation allows them to cut all day long. It’s really quite hard to make a mistake,’ confirmed Mr Talbot.