Konica Minolta has released five new digital front-ends (DFEs) based on the EFI Fiery FS500 Pro platform, the first to reach the market, and reported that installations of its KM-1 B2 UV press now account for 10% of the global market.

The new Fiery DFEs drive KM’s AccurioPress models across the revamped toner print range from the entry-level C4080/4070 and AccurioPrint C4065 introduced in December 2020, through the 100/90ppm light production C7100/7090 launched in June 2021 and up to the 140ppm production models C14000/12000 that arrived in October 2019.

The Fiery FS500 platform was announced by EFI in October 2021 and is claimed by EFI to be up to 36% faster than previous generations on image-intensive jobs such as photobooks, while reducing errors and waste through the inclusion of Fiery Preflight tools, supported by Fiery JobExpert ‘intelligent’ automation and native Adobe PDF Print Engine 5.5 workflow.Colour accuracy and consistency are said to be improved via a new version of Fiery Spot Pro for optimisation of spot colour reproduction via standard CMYK presses.

Inline finishing processes via Konica Minolta’s TU-510 inline four-edge trimmer and creaser are supported in the Fiery Finishing Designer module, supplied with the Fiery Command Workstation software. This provides a visual interface showing cut, crease and perforation marks against the job content.

‘The Fiery FS500 Pro new platform offers advanced speed, higher automation and more capability than other digital front ends,’ said John Henze, vice president of sales and marketing, EFI Fiery. ‘Intelligent automation solutions in these new EFI Fiery DFEs also save customers labour cost and time by minimising the need for manual inspection of print jobs, improving automated management, and eliminating the need to print a test file to determine where to place finishing lines.’

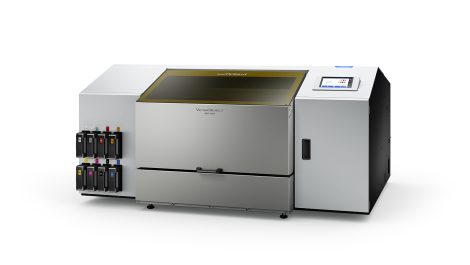

Meanwhile, Konica Minolta has also continued to sell its AccurioJet KM-1e B2 inkjet press. The company claims to have tripled its installed base to reach 10% of the global market share of B2 digital presses, and says it has ‘close to’ 30 installations in Europe, though no global total was given.

KM said its customers are ‘significantly’ increasing average page volumes every year, across a wide range of applications that includes book printing, packaging, direct marketing, commercial printing or offset replacement. The press has INGEDE de-inking accreditation for both uncoated and coated papers, which includes recycled grades.

Hidetoshi Omo, Head of Centre of Competence, KM-1 at Konica Minolta Business Solutions Europe, commented, ‘Opportunity is everywhere. Working closely in partnership, we are helping customers to ignite print possibilities in a sustainable way through injecting new-found creativity in their continued digital transformation. Our own customer experience is that inkjet is very much a growth market in which printers want to invest.

‘However, for us it is not just about machine sales – we accompany our customers on their digital transformation journey and are always there when they need us. Thinking of service engineers as just one example, we are proud to have 45 dedicated KM-1 and KM-1e service engineers across 17 countries in Europe,’ he added.

Digital Printer will be looking detail at B2 presses – both inkjet and toner – in the forthcoming May/June issue. If you are not already registered to receive the magazine, you can do so free of charge here.