Galloways has invested close to £2 million in Heidelberg equipment, including a Versafire EV digital press as well as Speedmaster CX 102 B1 litho model, in a move intended to strengthen the company’s position as it heads towards its 150th anniversary next year.

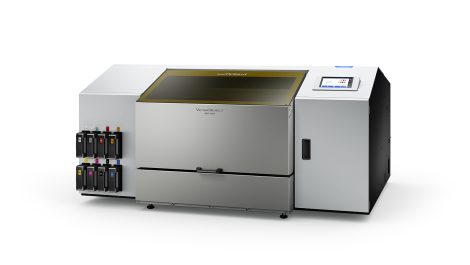

With digital now accounting for 25-30% of its turnover, the Cheshire-based company has purchased a Versafire EP digital press. The new machine can produce 3500 A3 simplex pages an hour, compared to the 1000 an hour from Galloways’ existing Linoprint. It also extends the stock range with its ability to handle up to 470gsm board.

Galloways has also added a B1 Speedmaster CX 102-5+L, litho press with a fifth unit for special colours and a coater. The company will be making use of Heidelberg workflow software which will allow it to send print jobs to either press. This is seen as key to higher output and maximum efficiency at its Poynton plant where the presses will be installed.

Director Matt Galloway explained the significance fo the Prinect workflow: ‘When we visited Germany to look at the CX 102 we were shown the workflow and process control that was now possible. We recognised that this is the key to maximising efficiency and the Production Manager will link prepress, press and MIS seamlessly and give us even greater colour control. It works across both litho and digital so we simply have to decide which output device to send the work to. We have bought Production Manager on a subscription deal which also means we get regular updates. With this investment we are putting ourselves in a very competitive position by being cost-effective for a range of commercial work, and some packaging.’