Pureprint Group has announced a major new round of investment to increase its digital and on-demand print capacity. The decision was made to address growing demand from publishing, brand, and e-commerce clients.

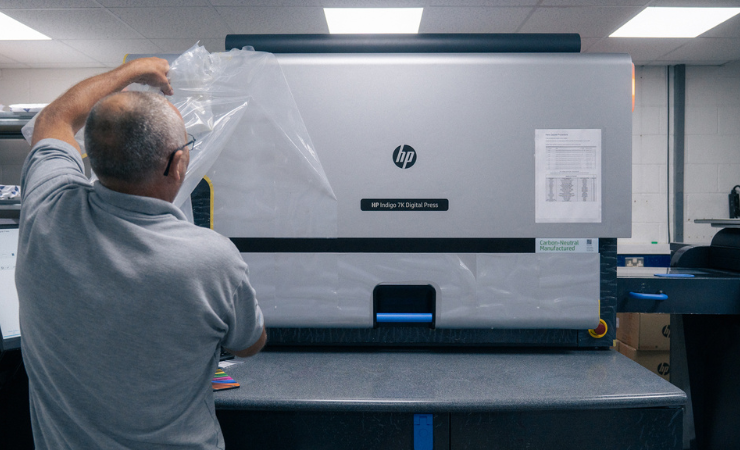

Unwrapping the HP Indigo 18k

The investment includes upgrades to the company’s Uckfield digital plant and the relocation of digital print and binding equipment to its Ashford Colour site in Gosport. Both operations are now connected via Pureprint’s technology platform, enabling on-demand production and intelligent job routing across the network.

A central part of the expansion is the addition of three new HP Indigo presses – two 7Ks and one 18K – at Uckfield, alongside upgrades of two existing HP Indigo 100Ks to 120K models planned for early 2026. Two Indigo 7900 presses and a Horizon BQ-470 PUR binding line have also been relocated to Gosport, bringing the Group’s total Indigo fleet to seven devices.

New finishing equipment has been installed to complement the digital expansion, including a Horizon BQ-500 PUR binder with HT1000 variable trimmer, Autobond 76 Mini Laminator, Zeno 360 IND case making and casing-in systems, and a Duplo 648 with inline folder.

“These investments support growing volumes from our roster of on-demand publishers, brands, and web-to-print partners,” said Mark Handford, CEO of Pureprint Group. “We’re particularly interested to see how AI and HP’s new productivity tools will help shape the future of our operations. The new devices have bedded in well and are fully operational ahead of the peak season.”

This investment follows earlier enhancements at Pureprint Imprint’s Newcastle site, including new Durst printers and PlastGrommet banner lines, and last year’s major Uckfield upgrade featuring a new Heidelberg litho press. Together, the developments highlight Pureprint’s ongoing commitment to innovation, capacity and sustainable growth across its UK operations.