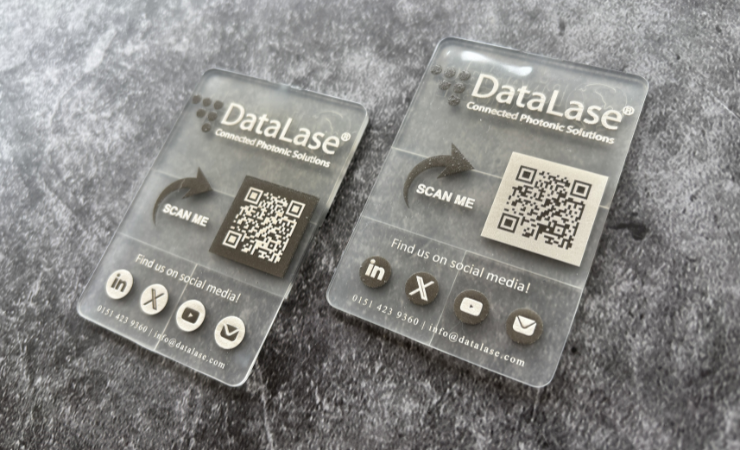

DataLase has unveiled a new dual-colour masterbatch pigment technology aimed at enhancing laser marking on clear plastic substrates. The innovation allows for a colour transition from clear to both black and white using a single pigment and a single pulsed fibre laser source.

The development enables high-contrast inline code verification directly on packaging and other applications, providing a cost-effective alternative to traditional labels, adhesives, and other consumables. Removing the consumables simplifies recycling and reduces waste, while supporting personalisation, digital product passports, and promotional messaging.

“This dual colour masterbatch represents a significant step forward in our pigment technology,” said Ally Grant, chief technology officer at DataLase. “By enabling both black and white colour transitions from a single pigment and laser source, we’re helping our customers achieve superior code visibility on clear plastics, while also supporting their drive for greater sustainability and efficiency. This advancement opens up new possibilities for packaging design, production flexibility and supply chain connectivity.”

The solution is compatible with a variety of plastics, including PET, PP, PE and PVC, and can be used in both rigid and flexible packaging formats. Liquid masterbatch dosing is recommended to reduce haze, though pellet formats are also available.

Available now, the pigment technology is part of DataLase’s patented portfolio and targets brand owners and packaging producers looking to improve traceability and meet sustainability goals.