As part of a major expansion, Berkshire-based Chroma has added UV flatbed printing and cutting capabilities to its wide-format armoury with the purchase of a Yotta flatbed and Sinajet cutting table, both provided by Service Offset Supplies (SOS).

Located in Theale near Reading, the full service print company, which has HP Indigo digital and Ryobi litho presses, moved into wide-format three years ago with a Roland DG print-and-cut roll-fed model, to which a second Roland unit was added last year. Operations director Justin Earl explained the move into flatbed thus:

‘These [Roland] machines have been a big success for us. To date much of our work has required us to mount vinyl to materials such as graphic boards, foam PVC or aluminium composite – so with an increasing workload it made sense for us to look at direct-to-media printing which would allow us to cut out the mounting stage. We were also increasingly being asked to produce work that could only be done on a flatbed machine and we were keen to bring this in-house.’

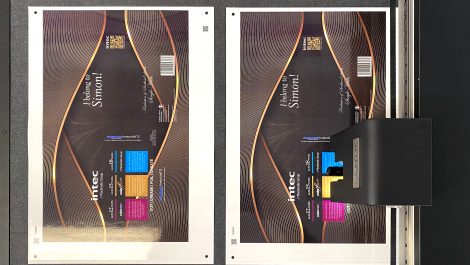

The Yotta Fr2513-R5 supplied by SOS is a 1.3 x 2.5m UV-curing flatbed that can handle material up to 10cm thick and offers white and clear varnish in addition to CMYK plus ‘lights’, all delivered via Ricoh Gen 5 printheads. The Sinajet DK2513 cutter matches the flatbed format and offers a variety of cutting heads to deal with various media up to 25mm thick at speeds of up to 1.8m/sec and with accuracy greater than 0.1mm.

Mr Earl justified the choice of the less well-known equipment, describing the Yotta flatbed as ‘a competitively priced entry-level machine, but it seems to be quicker and more capable than the more expensive alternatives in its class.’ Tests at an existing Yotta site confirmed the quality and performance.

He added, ‘We chose the flexible ink option for the machine as we felt this would enable us to offer the broadest range of end products to our customers. Another feature we really like is the option to increase capacity in future by adding more print heads. Although we will mainly be producing rigid signs and point of sale, we are seeing more demand for packaging including high-end, short-run projects, which is why we also included spot varnish in the spec.’

Of the Sinajet unit, Mr Earl said, ‘The cutter is an amazing piece of kit. Jobs which used to take half an hour to cut by hand can now be completed in minutes and with 180 tooling options it is extremely versatile.’