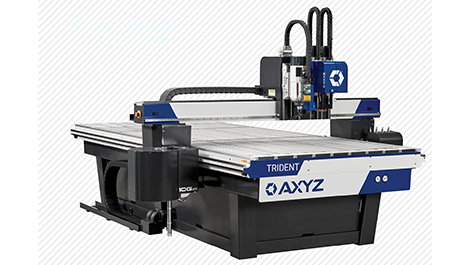

AXYZ Automation Group has introduced an upgraded version of its Trident print finishing system which it says has ‘radically’ improved automation, configurability and productivity capabilities.

The new system incorporates a stronger modular solid steel welded frame construction which better accommodates more vigorous machine operation. It also allows for an expanded range of routing, cutting and creasing tools, including a four-position tangential knife-changer.

Additional enhancements include improved dust extraction and spray mister units for more efficient machine tool lubrication and cooling and increased gantry height to enable the processing of materials up to 125mm thick. It also incorporates an AXYZ Vision System for precise material registration, alignment and routing/cutting accuracy.

The AXYZ Trident is available in four standard sizes, with processing bed areas ranging from 1524 x 1219mm up to 2159 x 3048mm and a processing length of 1259mm, customisable up to 15m if required.

Trident will handle a wide range of flexible, semi-rigid and rigid materials including aluminium and aluminium composites, other non-ferrous metals, acrylic and associated plastics, laminates, vinyl, corrugated boards, cardboard and paper.