DIrect-to-textile digital printer manufacturer Kornit Digital has introduced a ‘dry digital softening process’ that aims to restore the hand feel of a wide range of textile types after digital printing, opening up wider opportunities for users of its printers, and reducing the environmental impact of fashion and other garment production.

The NeoPigment Robusto Softener is an addition to the eponymous ink range launched by Kornit at ITMA in summer 2019. Its application requires the use of one channel in each printhead, and it is applied last, after the ‘fix on the fly’ fixation process. The softener is printed only where inks have been applied and so involves no wastage. Kornit CMO Omer Kulka said that the use of the softener adds five to seven per cent to unit print costs, but pointed out that this is more than offset by the reduction in overall processes required, as it’s done in the same pass as the printing and is a dry process, so no water is required or waste produced. There is some scope for trading off the softening effect against cost, if required.

There is no performance penalty either, according to Mr Kulka, and he reported that good results have been achieved on both natural and synthetic fabrics, including both silk and polyester, with no impact on light-fastness. Washability is also said to be good and to only improve the hand feel.

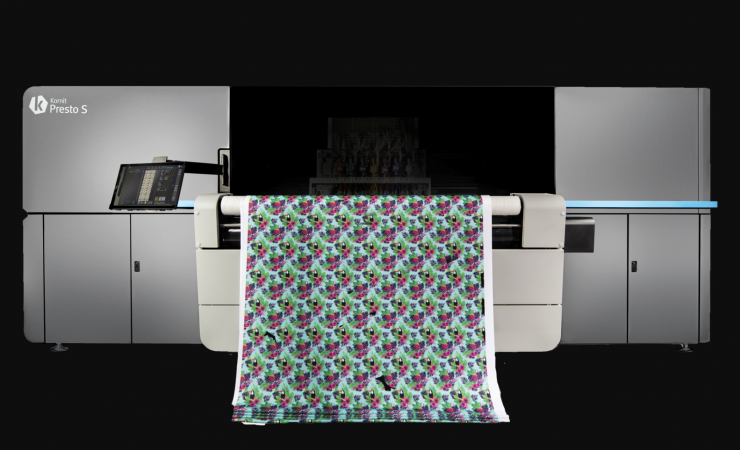

The use of the new softener is most likely to be in Kornit’s Presto 10-channel range of printers, which can support six colour (CMYK plus red and green) print plus fixation and softener. The NeoPigment Robusto inks also work in the Allegro range but Mr Kulka said that these do not have spare channels to accommodate it without losing an existing ink.

‘The new Softener addresses the final sticking point we’ve encountered for high fashion and other markets considering a move to digital printing – and that’s the touch, the physical feel of the finished piece,’ said Kornit CEO Ronen Samuel . ‘Being able to produce precisely and only what is sold, and doing so in a manner that reflects the premium modern consumers place on community and social responsibility, is the key to stability and growth in these uncertain times.’

Commercial availability of the softener was not confirmed but Kornit says that multiple beta sites have been running over the last six months, ‘dozens’ of demonstrations have been made and were instrumental in clinching at least one sale for a high street women’s wear brand. The company is intending to exhibit at the rescheduled Fespa 2020 in Madrid in October and will be demonstrating the technology there.