Plastic card manufacturer Nitecrest is implementing the Tharstern MIS to help streamline its workflows and increase productivity in its litho and digital production operations.

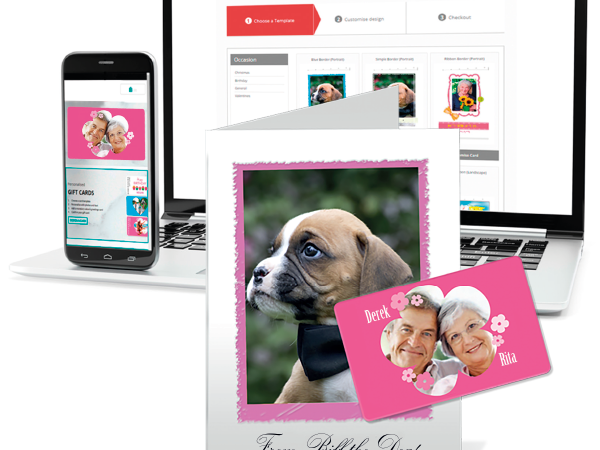

Working with many high street retailers, the Lancashire-based company has been producing gift, loyalty and membership plastic cards for 25 years and produces over 5 million cards a day, exporting to more than 140 countries. .

One of the factors driving the decision was the lack of responsiveness from the existing MIS. The Tharstern system is expected to be more responsive and to eradicate repetition. Nitecrest researched various MIS providers, but felt that Tharstern’s stood out; positive comments from other Tharstern MIS were also influential in reading the decision.

The visibility of projects and milestones in one place, instead of using different packages, will increase interdepartmental communication and speed up the process from estimating through to final production.

‘We are excited about how Tharstern will help to ensure we are working in the most efficient and productive manner as part of our 5s lean management programme. We were very impressed with how structured and professional our Tharstern customer experience was throughout the whole process, from initial contact, to discovery visit, to various other meetings discussing the potential implementation, it was relaxed but very productive,’ said Lee Moran, Nitecrest’s customer services manager.