Meteor’s Dan Harvey reports increasing interest in 3D printing

Following two years of exceptionally strong growth, systems integrator Meteor Inkjet has moved into new and larger premises in Harston near Cambridge.

The Global Graphics subsidiary, acquired in December 2016, develops control electronics and software for a wide range of inkjet printheads used in wide-format and single-pass printers. The firm’s sales have more than doubled in the last two years, largely due to strong export sales, with 98% of business going outside the UK. China is a particularly strong market but 19 other countries have also availed themselves of Meteor’s expertise.

The new facilities at Harston Mill have space for the growing team as well as purpose-built labs for developing, testing and demonstrating electronics, software and components.

‘We were getting very tight on office, lab and stockroom space at our previous location,’ explained managing director Clive Ayling, ‘and we lacked sufficient room to host an increasing number of customer visits. In many respects our expansion marks a new beginning as we move out of the premises where the company was founded by TTP Group 12 years ago into a space that we’ve designed to suit our specific requirements.”

Meteor works with all the major printhead manufacturers to develop components for printing devices that are used markets including ceramic tiles, packaging, commercial print, textiles, product decoration, signs, displays & décor, labelling, functional print and 3D.

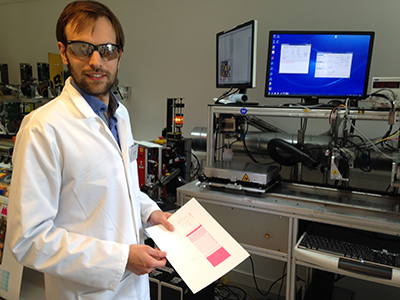

Meteor electronic engineer Dan Harvey told Digital Printer that the company has seen increased interest in 3D print from its customers and a shift in focus from working primarily with printer vendors to cooperation with printhead manufacturers to produce “ready to go” printhead and control electronics packages that the printer manufacturers can incorporate into their products and so shorten their development time.