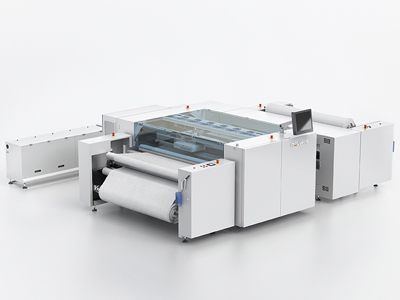

The Mouvent TX801 textile printer – described as “durable, compact and accessible”

Jean-Pascal Bobst introduced his company’s new strategy for digital technology, including a new textile printer, to the world’s media at Wetzikon, Switzerland, writes Sean Smyth.

Bobst is the market leader for printing and finishing in many packaging applications and it has been working to develop a digital system since 2009. It designed a very powerful corrugated printing system using Kodak heads and ink, but this has not proved to be a commercial success at its first installations.

The company will now discontinue its relationship with Kodak and instead has decided to develop totally new systems internally, setting up a new venture called Mouvent to do so. Bobst owns 50.1% of the shares in the new company and the rest are owned by Radex, a group of engineers formerly with Graphtec, the Swiss developer of inkjet systems bought by Domino in 2012.

The team has developed a modular approach, creating what they call an inkjet cluster which uses Fujifilm Samba printheads in an easily scalable unit. Each cluster acts independently, meaning it is much simpler for the developers to scale up a system rather than having to create a series of different print bars for various applications and print widths. They claim it delivers very high quality with a short development and implementation time. The plan is to roll out a range of machines, both web- and sheet-fed, across a variety of applications.

The first machine is the Mouvent TX801 for textile printing, a 1.8m print width 8-colour design that uses a multi-pass scanning mechanism with reactive inks for direct printing at up to 200sqm/hr. There will be further models to follow for the textile sector, promising performance improvements. The other machines presented at the launch were narrow web label presses that will be launched at Labelexpo.

It is refreshing (and incredibly rare) for a company to admit that a technology has not worked as it wanted it to. Bobst quite rightly has a reputation as a premium equipment supplier across pack printing, conversion and finishing. The machines are built to the highest level of Swiss engineering precision, last forever (well, for many, many years), and the company will not provide equipment that does not live up to these very exacting standards. Bobst is the epitome of a conservative Swiss company.

There are not many examples of analogue press suppliers making the successful transition to digital alternative; hopefully this fresh approach with a totally new organisation will prove to be the model to follow.

___

Sean Smyth is group technical editor at Whitmar Publications.